- Home

- >

News

X-ray crystal orientation analyzers are vital for developing high-performance optoelectronic materials like those in LEDs and solar cells. They enable precise control of crystal structure during growth and thin-film production, ensuring optimal quality. Essential for R&D, they bridge fundamental science and industrial manufacturing, supporting innovation in next-generation devices.

The Physical Foundation of X-ray Diffractometer (for Stress Measurement): In-depth Derivation of Diffraction Geometry and the Stress-Strain Relationship

A premier X-ray crystal analyzer enabling precise exploration of material microstructures. Its advanced PLC control, modular design, and robust 5KW output ensure high reliability for global R&D and industrial quality control applications.

Dandong Tongda's multifunctional residual stress meters provide high-precision testing for aerospace, automotive, and new energy industries. Featuring multi-material compatibility and portable designs, they ensure component safety and durability, gaining global recognition with full international compliance and support.

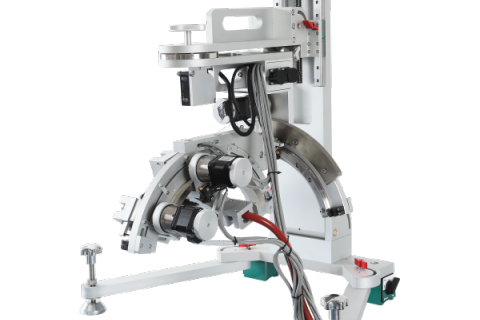

Amidst ongoing breakthroughs and technological innovations in global materials science, China's scientific instrument manufacturing industry is steadily rising to prominence. The TDF Series X-ray Crystal Analyzer, developed by Dandong Tongda Technology Co., Ltd., represents a leading example of domestically produced high-end analytical instrumentation. It is gaining traction in global scientific research and industrial sectors precisely due to its exceptional performance and reliable precision. The TDF Series X-ray Crystal Analyzer is a major analytical instrument designed for investigating the internal microstructure of substances. Its key applications encompass crystal orientation, defect inspection, lattice parameter determination, and residual stress measurement. Whether analyzing the structure of plates and rods, or deciphering the structure of unknown materials and single crystal dislocations, this equipment delivers accurate and reliable data support. In modern fields like materials science, semiconductor manufacturing, new energy development, and pharmaceuticals, a deep understanding of material microstructure has become the cornerstone of technological progress. The TDF Series is engineered for this purpose – empowering scientists and engineers worldwide to unlock the secrets of material properties. Vertical Tube Housing & Four-Port Design The TDF Series X-ray Crystal Analyzer incorporates a unique vertical tube housing design with four usable ports simultaneously. This innovative design significantly enhances operational efficiency, allowing users to switch rapidly between multiple experimental channels and save valuable research time. Precision Control with PLC Technology Equipped with an imported PLC control system, the TDF Series X-ray Crystal Analyzer demonstrates outstanding performance in control precision and anti-interference capabilities. This system not only enables precise control of high-voltage switching and lifting operations but also features an automatic X-ray tube training function, effectively extending the service life of both the X-ray tube and the entire instrument. For experimental scenarios requiring long-term, continuous operation, this reliability substantially reduces the risk of equipment failure and potential data loss. Powerful and Stable High-Voltage Generation System The high-voltage generator of the TDF Series performs exceptionally well, offering a tube voltage adjustable from 10 to 60 kV and a tube current range from 2 to 80 mA, with a rated output power of up to 5 kW. The stability of tube voltage and current reaches 0.3‰, ensuring highly reproducible experimental data. The system is also equipped with multiple protection functions (e.g., no voltage, overvoltage, no mA, over-power, no water, X-ray tube overtemperature), providing comprehensive safety assurance. Versatile X-Ray Tube Configurations To accommodate diverse analytical needs, the TDF Series offers a choice of various target materials, including Cu, Co, Fe, Cr, Mo, and W. With a rated power of 2.4 kW and focal spot options of point focus (1×1) and line focus (1×10), users can select the most suitable configuration based on sample characteristics and analytical objectives. Comprehensive Safety Protection Design Safety performance is another standout feature of the TDF Series X-ray Crystal Analyzer. Utilizing high-density, high-transparency lead glass for the X-ray protective shielding, the external radiation leakage is maintained at ≤ 0.1 μSv/h – a level well below international safety standards – ensuring reliable protection for operators. Configurations for Diverse Application Scenarios The TDF Series X-ray Crystal Analyzer supports various X-ray cameras, including Laue cameras (large/small powder), flat panel cameras, 3D sample stages, and Multiwire cameras (US-made). This flexible configuration scheme enables the instrument to adapt to a wide range of requirements, from fundamental research to high-end materials analysis. For applications demanding high-precision positioning, the TDF Series X-ray Crystal Analyzer offers a maximum positioning speed of up to 1500°/min, ensuring fast and accurate data acquisition. Whether for analyzing unknown materials in scientific research or for quality monitoring in industrial production, the TDF Series provides a dependable solution. As cutting-edge fields like new materials, new energy, and semiconductors continue to develop rapidly, the demand for material microstructure analysis is growing, and the required precision is constantly increasing. The TDF Series X-ray Crystal Analyzer will continue to evolve and upgrade to meet the latest needs of the global scientific and industrial communities. Dandong Tongda Technology Co., Ltd. remains committed to its philosophy of technological innovation and quality first. We will continue to provide global users with superior products and services, working hand-in-hand with scientists and engineers worldwide to jointly advance materials science and enhance industrial quality standards. We invite global partners and users to inquire and discuss collaboration opportunities. Discover more about the technical details and application cases of the TDF Series X-ray Crystal Analyzer. Let's join hands to explore the mysteries of the microscopic world of materials and jointly drive technological innovation and industrial progress!

The multi-functional residual stress analyzer developed by Dandong Tongda Technology Co., Ltd. is designed to meet the needs of fast and accurate measurements in both laboratory and field environments. Based primarily on the X-ray diffraction principle, it enables non-destructive testing of the residual stress state inside materials. Versatile All-in-One Analysis This analyzer integrates multiple material analysis functions, significantly enhancing equipment utility and efficiency: Residual Stress Analysis: Supports various measurement modes such as standard同倾法 (omega-inclination), standard侧倾法 (psi-inclination), and standard摇摆法 (oscillation), capable of determining principal stresses and shear stresses for a comprehensive stress state evaluation. Retained Austenite Analysis: Employs the four-peak method for retained austenite testing, with fully automated data calculation for quick results. Diffraction Phase Analysis: Used to analyze crystal structures, chemical composition content, and distribution, helping researchers gain deeper insights into material constitution. Grain Size Analysis: Supports grain size evaluation from nanoscale to sub-micron scale, particularly suitable for fine grains ≤200 nm. Technical Features and Performance This instrument boasts multiple technical features aimed at ensuring precision, stability, and ease of use: High-Precision Measurement and Control: Utilizes a high-precision fully closed-loop vector drive servo system to ensure measurement accuracy and repeatability. Efficient Data Acquisition: Equipped with a multi-channel silicon strip linear array detector, which provides noise-free performance, high-intensity measurement, and rapid data collection to enhance detection efficiency. Portable Design: Features a lightweight construction, making it suitable not only for laboratory environments but also for on-site rapid measurements, adapting to various testing scenarios. User-Friendly Operation: Integrates Windows OS or automation functions, supporting one-click testing and real-time result display, lowering the operational barrier. Modularity and Safety: Employs a PLC control system with modular design for ease of operation and stable performance. Safety-wise, its low-power X-ray design complies with relevant safety standards, with radiation levels significantly below the annual public dose limit. Broad Application Fields Dandong Tongda’s multi-functional residual stress analyzer has extensive applications, covering almost all industrial sectors and research institutions requiring evaluation of material mechanical properties: Manufacturing Quality Control: Used to detect residual stresses in stamped, cast, and rolled parts during processing. Automotive Industry: Tests residual stresses in critical components such as camshafts and connecting rods to ensure reliability and durability. Aerospace: Evaluates working loads in critical areas of aerospace materials to assess safety. Materials Science Research: Applicable to various metal materials (e.g., carbon steel, alloy steel, titanium alloy, nickel-based materials), glass, and composite materials for residual stress, retained austenite, phase, and grain size analysis. Dandong Tongda Technology Co., Ltd.’s multi-functional residual stress analyzer demonstrates the company’s technical expertise in the field of material testing by integrating multiple analytical functions. This instrument provides engineers and researchers with a window into the intrinsic stress state of materials, helping to control product quality at the source, optimize process parameters, and thereby enhance product reliability and durability.

In the field of modern technology, many high-tech products—from smartphone screen substrates to core components of laser generators—rely on a fundamental material: synthetic single crystals. The precision of the cutting angle of these crystals directly determines the performance and yield of the final products. The X-Ray Orientation Analyzer is an indispensable instrument in the precision manufacturing of crystal devices. Utilizing the principle of X-ray diffraction, it accurately and rapidly measures the cutting angles of both natural and synthetic single crystals, including piezoelectric crystals, optical crystals, laser crystals, and semiconductor crystals. Dandong Tongda Science and Technology Co., Ltd. offers a range of reliable X-Ray Orientation Analyzers tailored to the research, processing, and manufacturing needs of the crystal materials industry. 01 Versatile Machine for Diverse Crystal Orientation Needs Dandong Tongda's X-Ray Orientation Analyzers primarily include models such as the TYX-200 and TYX-2H8. The TYX-200 model boasts a measurement accuracy of ±30″, with a digital display and a minimum reading of 10″. The TYX-2H8 model is an improved version of the TYX-200, featuring enhancements in the goniometer structure, load-bearing track, X-ray tube sleeve, support body, and an elevated sample stage. These improvements enable the TYX-2H8 to handle samples weighing 1–30 kg with diameters of 2–8 inches. It retains a digital angle display and a measurement accuracy of ±30″. 02 Advanced Technical Features for User-Friendly Operation Dandong Tongda's X-Ray Orientation Analyzers are designed with practicality and reliability in mind. Their user-friendly operation requires no specialized knowledge or advanced skills from the operator. The instrument features a digital angle display, ensuring intuitive and easy-to-read measurements while minimizing the risk of misreading. The display can be zeroed at any position, allowing direct reading of the wafer angle deviation. Some models are equipped with dual goniometers for simultaneous operation, significantly improving detection efficiency. A special integrator with peak amplification enhances measurement accuracy. The X-ray tube and high-voltage cable adopt an integrated design, improving high-voltage reliability. The detector high-voltage system uses a DC high-voltage module, and the vacuum suction sample stage further enhances measurement accuracy and speed. 03 Dedicated Sample Stage Designs for Various Testing Needs To meet the measurement requirements of samples with different shapes and sizes, Dandong Tongda offers a variety of specialized sample stages: TA Sample Stage: Designed for rod-shaped crystals, it features a load-bearing track and can test crystal rods weighing 1–30 kg with diameters of 2–6 inches (expandable to 8 inches). This stage can measure reference surfaces of rod-shaped crystals as well as surfaces of wafer-shaped crystals. TB Sample Stage: Also designed for rod-shaped crystals, it includes a load-bearing track and V-shaped support rails. It can test crystal rods weighing 1–30 kg, with diameters of 2–6 inches (expandable to 8 inches) and lengths of up to 500 mm. It measures end faces of rod-shaped crystals and surfaces of wafer-shaped crystals. TC Sample Stage: Primarily used for detecting the outer reference surfaces of single-crystal wafers such as silicon and sapphire. Its open-design suction plate avoids X-ray obstruction and positioning inaccuracies. The stage's suction pump securely holds wafers sized 2–8 inches, ensuring precise detection. TD Sample Stage: Designed for multi-point measurements of wafers such as silicon and sapphire. Wafers can be manually rotated on the stage (e.g., 0°, 90°, 180°, 270°) to meet specific customer measurement needs. 04 High-Performance Model for Large Sample Challenges For large and challenging sample detection, Dandong Tongda's X-Ray Orientation Analyzers demonstrate exceptional performance. The TYX-2H8 model, for example, is particularly suitable for orienting sapphire crystal ingots and rods. This instrument supports measurements of sapphire A, C, M, and R crystal orientations, with an adjustable measurement range of 0–45° via electric automation. Its technical specifications are impressive: Copper-target X-ray tube with grounded anode and forced air cooling. Adjustable tube current: 0–4 mA; tube voltage: 30 kV. Operation via computer or touchscreen control. Synchronized movement of the X-ray tube and detector; electric-driven rotary table. Total power consumption: ≤2 kW. Most notably, its sample handling capacity includes crystal ingots weighing up to 30–180 kg, with maximum dimensions of 350 mm in diameter and 480 mm in length. These capabilities make it suitable for large sample detection in most industrial scenarios. 05 Broad Applications Supporting Multiple Industries Dandong Tongda's X-Ray Orientation Analyzers are widely used across various industries involved in the research, processing, and manufacturing of crystal materials. In the semiconductor industry, they enable precise orientation cutting of silicon wafers. In the optoelectronics field, they are used for precision processing of sapphire substrates, optical crystals, and laser crystals. In the piezoelectric materials sector, they ensure accurate cutting angle measurements for stable end-product performance. The instruments are particularly well-suited for sapphire materials, which are in high demand due to their hardness, high light transmittance, and excellent physicochemical stability. Sapphire is widely used in LED substrates, consumer electronic screens, and optical windows. Dandong Tongda's X-Ray Orientation Analyzers have become essential tools in China's crystal material research and manufacturing fields, thanks to their reliable performance, diverse configurations, and strong adaptability. Their modular design and variety of sample stage options allow users to select configurations that meet specific needs, ensuring high detection accuracy while improving work efficiency. Whether for research institutions or manufacturing quality control and process optimization, these instruments provide robust technical support, empowering users to achieve breakthroughs in precision manufacturing.

Dandong Tongda's X-ray Crystal Analyzer adopts advanced X-ray diffraction technology, enabling non-destructive detection of microstructural information in various materials. Whether it's single crystal orientation, defect inspection, lattice parameter measurement, or residual stress analysis, this instrument provides accurate and reliable test data, offering solid support for material research and quality control. The instrument is equipped with a highly stable X-ray generator that delivers exceptional performance. The tube voltage can be precisely adjusted within the range of 10-60kV, and the tube current can be regulated from 2-60mA, with a stability of no more than ±0.005%. This ensures highly repeatable and accurate test results, providing researchers with dependable data assurance. Dandong Tongda's X-ray Crystal Analyzer integrates intelligent control and comprehensive safety protection. It features an imported PLC automatic control system, enabling unattended automatic timed measurements. The multi-level safety protection system includes no-pressure, no-current, over-voltage, over-current, over-power, no-water, and X-ray tube over-temperature protections, ensuring the safety of operators. The TDF series X-ray crystal analyzer adopts a vertical tube housing with four windows that can be used simultaneously. It utilizes imported PLC control technology, which offers high precision and strong anti-interference capabilities, ensuring the reliable operation of the system. The PLC controls the switching and adjustment of high voltage and includes an automatic training function for the X-ray tube, effectively extending the service life of both the X-ray tube and the instrument. The instrument's radiation protection enclosure is constructed with high-density, high-transparency leaded glass, with external radiation leakage far below national safety standards, allowing researchers to conduct experimental studies in a secure environment. As a national high-tech enterprise, Dandong Tongda Technology Co., Ltd. has a comprehensive quality management system and a technical R&D team. Its products not only meet domestic market demands but are also exported to numerous countries and regions, demonstrating the strength and capability of China's scientific instrument manufacturing. Dandong Tongda's X-ray Crystal Analyzer, with its outstanding performance and reliable quality, has become a powerful assistant in the field of material analysis. It helps researchers and engineers unveil the layers of the material world and explore more unknown possibilities.

X-ray crystal analyzer operates on Bragg's law, measuring diffraction patterns to determine crystal structure. Key components include X-ray tube (2.4kW, multiple targets), spectroscopic crystal, detector, and goniometer. TDF series features 4-window operation, PLC control, and automated tube training. Widely used in materials science, chemistry, biology, and geology for structural analysis.

The TDF series X-ray crystal analyzer is a large-scale analytical instrument and X-ray instrument used to study the internal microstructure of materials. It is mainly used for single crystal orientation, defect inspection, determination of lattice parameters, determination of residual stress, study of the structure of plates and rods, study of the structure of unknown substances, and single crystal dislocations.

The TDF series X-ray crystal analyzer delivers exceptional performance in microstructure analysis, supporting single crystal orientation, defect detection, and stress measurement. Featuring a vertical tube design with multi-window operation and imported PLC control, it ensures high precision, safety compliance (radiation <0.1 µSv/h), and adaptability across industries. Backed by ISO certification and global exports, this instrument empowers scientific and industrial advancements worldwide

Product Spotlight: Dandong Tongda's X-Ray Crystal Analysis Solutions Dandong Tongda Science and Technology introduces its advanced X-ray crystal analysis equipment, delivering precision and reliability for industrial applications. The TDF Series X-Ray Crystal Analyzer combines powerful analytical capabilities with industrial-grade reliability. Featuring four operational windows and PLC control technology, it serves high-end manufacturing sectors including semiconductor wafer inspection, aerospace component stress evaluation, and laser crystal processing. Our X-Ray Crystal Orientators (TYX-200/TYX-2H8) enable rapid, precise measurement of crystal cutting angles with accuracy up to ±30 arcseconds. Capable of handling samples up to 30kg, these instruments support directional cutting of piezoelectric, optical, laser, and semiconductor crystals. Both product lines utilize non-destructive X-ray diffraction technology, replacing traditional radioactive methods while improving processing efficiency and accuracy for crystal material research and manufacturing.