A Key to Safer High-End Equipment: The Multifunctional Residual Stress Meter

2025-10-29 16:22Amid the global manufacturing industry's accelerated pursuit of higher precision and reliability, residual stress testing has become crucial for ensuring the safety and durability of core components in sectors like aerospace, automotive, and new energy.

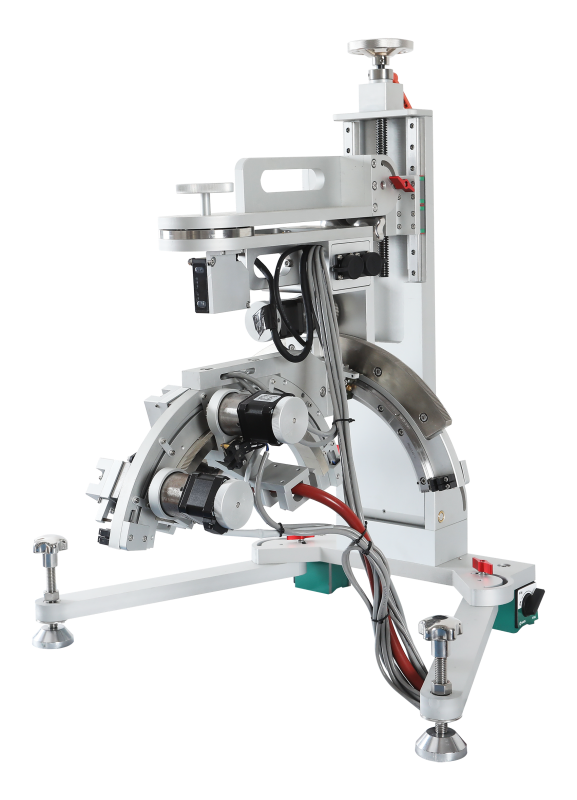

Dandong Tongda Science and Technology Co., Ltd.'s series of multifunctional residual stress meters, with their exceptional technical performance and flexible adaptability, are steadily gaining international market recognition, offering a robust solution for global industrial quality control.

Technological Leadership: High Precision and Multifunctional Integration

Tongda's multifunctional residual stress meters cover multiple models, including the TDTC-150, TD-RSD, and the porable TD-Mini, catering to diverse testing scenarios. Core innovations include:

High-Precision Measurement System: Uses a fully closed-loop vector drive servo system, achieving goniometer angle control accuracy of 0.001°. The 2θ range is 45°–170°, and the ψ angle extends to -57° to +57° (TD-RSD model), enabling stress analysis on complex surfaces.

Multi-Target Material Compatibility: Supports various target materials (Cr, Cu, Mn, Co, V, Ti, Fe, Mo), allowing optimal excitation source selection for steel, titanium alloys, nickel-based materials, and composites.

Advanced Micro-Area Analysis: A minimum slit diameter of 0.1mm, combined with laser positioning, allows precise residual stress measurement in tiny areas, ideal for welds and coatings.

High-Efficiency Detection: Incorporates a high-speed array photon counting detector with a count rate exceeding 1×10⁹ cps, reducing single-point measurement time to 2–4 minutes.

Functional Diversity: Four Core Detection Modules

The instruments integrate four key functions: residual stress analysis, residual austenite measurement, diffraction phase analysis, and grain size analysis. The software supports:

Stress Contour Mapping: Automatically generates visual stress distribution maps.

Rapid Austenite Measurement: Calculates residual austenite content automatically using the four-peak method in a single exposure.

Multi-Parameter Output: Displays normal stress, shear stress, peak intensity, integral width, and FWHM in real-time, complying with ASTM E915-21, EN15305-2008, and GB/T 7704-2017 standards.

Expanding Applications: From Lab to Factory Floor

Tongda's multifunctional residual stress meters serve critical roles in:

Aerospace: Evaluating stress and optimizing processes for engine blades and landing gear.

Automotive: Monitoring tensile orientation and welding residual stress in transmission shafts and gears to improve fatigue life.

New Energy & Electronics: Analyzing micro-area stress in battery films and semiconductor coatings to prevent interface failure.

Field Use: The portable TD-Mini, being lightweight and compact, enables rapid testing in the field and on production lines.

Global Support: Service Network and Localization

Tongda Technology has established a strong global after-sales framework:

Service Commitment: Offers a 1-year warranty (extendable), 72-hour on-site repair, and free on-site training and technical consultation.

International Compliance: Products are exported internationally, hold CE certification, meet various national safety standards, and feature multi-language software interfaces.