- Home

- >

News

The TDM-20 X-ray Diffractometer (Benchtop XRD) is primarily used for phase analysis of powders, solids, and paste-like substances. Based on the principle of X-ray diffraction, it enables qualitative and quantitative analysis, as well as crystal structure analysis, of polycrystalline materials like powdered samples and metal samples. It is widely applied in industries including industry, agriculture, national defense, pharmaceuticals, mineralogy, food safety, petroleum, and education/research. Core Principle: X-ray Diffraction, the Key to the Microscopic World The TDM-20 X-ray Diffractometer operates on the principle of X-ray diffraction. When X-rays illuminate a sample, they interact with the atoms in the sample and diffract. Different crystal structures produce unique diffraction patterns, much like individual fingerprints. By analyzing these patterns, the instrument precisely reveals key information about the sample's crystal structure, phase composition, and more, uncovering the secrets hidden at the microscopic level. Performance Breakthrough The TDM-20 X-ray Diffractometer (Benchtop XRD) surpasses the previous international standard of 600W, undergoing a comprehensive upgrade to 1200W. The instrument features simple operation, stable performance, and low energy consumption. It can be equipped with either a proportional detector or a new high-speed array detector, resulting in a significant leap in overall performance. Device Features Compact size and lightweight design High-frequency, high-voltage power supply design for lower overall energy consumption Supports rapid sample calibration and testing Simplified circuit control for easy debugging and installation Full-spectrum diffraction angle linear accuracy reaches ±0.01° Rich Accessories The TDM-20 can be paired with various accessories, including a 1D array detector, proportional detector, 6-position automatic sample changer, rotating sample stage, among others. Conclusion The TDM-20 X-ray Diffractometer (Benchtop XRD) , with its outstanding performance, user-friendly operation, and broad range of applications, has become an indispensable tool across numerous industries and research fields. It acts like a "detective" of the microscopic world, helping us unravel the mysteries of material structure and driving progress in various domains. If you too seek to delve deeper into the microscopic secrets of matter, consider the TDM-20 to embark on a journey of precise and efficient research and production.

The TDM-10 desktop X-ray diffractometer is a compact and high-precision phase analysis device. The following is a detailed introduction to the product: 1. Core functions and applications of TDM-10 desktop X-ray diffractometer (1) Phase analysis Suitable for qualitative and quantitative analysis of powder, solid, paste like materials, and thin film samples, it can identify the crystal structure, phase composition, and crystallinity in the samples. (2) Crystal structure analysis It can measure grain size, crystal orientation, macroscopic/microscopic stress, and structural properties of materials. (3) Industrial and Research Applications Widely used in fields such as geology, materials science, chemistry, biology, medicine, and nuclear industry, suitable for rapid laboratory testing and teaching demonstrations. 2. Technical characteristics of TDM-10 desktop X-ray diffractometer (1) Compact design and efficient performance Small size, light weight, low power consumption, easy to operate, suitable for desktop environments. Equipped with high-frequency and high-voltage power supply, the power can reach 1200W (refer to TDM-20 model), ensuring X-ray stability. (2) High precision measurement The measurement accuracy of diffraction peak position reaches 0.001 °, with excellent angular repeatability, meeting the requirements of high-precision analysis. By using the principles of Debye Scherrer geometry and Bragg's law, the crystal reflection signal is recorded through conical surface diffraction, achieving accurate phase identification. (3) Intelligent Control and Data Processing Computer controlled data acquisition, supporting real-time data acquisition and processing under Windows system, with an intuitive operating interface. Can be paired with array detectors (referring to the high-performance detector technology of TDM-20) to improve detection efficiency and sensitivity. 3. Applicable scenarios of TDM-10 desktop X-ray diffractometer (1) Research field Universities and research institutes are used for material research and development, crystal structure analysis, and characterization of nanomaterials. (2) Industrial applications Mineral identification, drug composition analysis, food safety testing (such as crystal impurity screening), etc. (3) Teaching Demonstration Easy to operate desktop device, suitable for student experimental teaching, covering the basic theory and practical operation of phase analysis. 4. Technical parameters of TDM-10 desktop X-ray diffractometer (1) Measurement accuracy: diffraction peak position accuracy of 0.001 ° (2) Control method: Computer control (Windows system) (3) Power supply: Low power design, high-frequency high-voltage power supply (4) Detector: Supports array detectors or proportional detectors (refer to TDM-20 accessories) (5) Sample stand: can be paired with a rotating sample stand or an automatic sample changer (optional accessory) 5. Product advantages of TDM-10 desktop X-ray diffractometer (1) High cost-effectiveness: Domestic equipment has outstanding performance and is much cheaper than imported equipment, making it suitable for laboratories with limited budgets. (2) Quick detection: Optimize calibration process, shorten testing time, and improve experimental efficiency. (3) Scalability: Supports multiple accessories (such as low-temperature cooling systems, in-situ battery accessories, etc.), which can be extended to special scenario analysis. 6. Related series and comparison of TDM-10 desktop X-ray diffractometer TDM-20 model: TDM-20 is an upgraded version of TDM-10, with higher power (1600W), new high-performance array detectors, support for automatic sample changers and other accessories, suitable for more complex industrial and scientific research needs. Other models: The Dandong Tongda TD series also includes high-resolution diffraction instruments such as TD-3500 and TD-3700, as well as TDF series crystal analyzers, covering multidimensional analysis needs. The TDM-10 desktop X-ray diffractometer has become the preferred equipment for laboratory phase analysis due to its compact design, high-precision measurement, and intelligent operation. It has a wide range of application scenarios, especially suitable for scientific research and industrial environments that require fast and accurate detection. If higher configuration is required, TDM-20 or other models in the same series can be considered.

X-ray irradiator is a scientific research equipment that uses X-rays to irradiate biological samples, materials, or small animals, and is widely used in fields such as biology, medicine, and materials science. 1. Core functions and technical principles of X-ray irradiation equipment (1) Functional positioning Biological research: used for DNA damage, cell mutagenesis, stem cell differentiation induction, tumor mechanism research, immunology and gene therapy experiments, etc. Medical applications: radiation disinfection, blood product processing, analysis of tumor cell apoptosis, pre-treatment for organ transplantation, etc. Materials and Environmental Science: Nanomaterial Modification, Food Radiation Quarantine, Soil Pollutant Analysis, etc. (2) Technical principles By accelerating electrons with high voltage to collide with metal targets, X-rays are generated; After optimization through filters, beam limiting devices, etc., the sample is irradiated to achieve targeted intervention by precisely controlling the dose rate, irradiation time, and range. 2. Key technical parameters of X-ray irradiation equipment (1) Radiation performance Tube voltage: 30-225kV (different models vary). Dose rate: 0.1-16Gy/minute, supporting precise and stepless adjustment. Dose uniformity: ≥ 95% (industry-leading level). Radiation angle and coverage area: The maximum radiation angle is 40 degrees, and the coverage diameter is up to 30cm. (2) Operation and Safety Design Intelligent control: touch screen operation interface, data export function (compatible with Excel). Safety protection: lead shielded cabinet, environmental dose<20 μ R/h (5cm away from equipment), multiple interlocks and fault alarms. Cooling system: Closed loop cooling technology extends the lifespan of X-ray tubes (up to 2000 hours). (3) Applicable sample types Cells, tissue organs, bacteria, mice, rats, etc., support irradiation of small animals in a conscious or anesthetized state. 3.Typical products and manufacturers of X-ray irradiation equipment Domestic representative: Dandong Tongda Technology Co., Ltd Advantages: Localization reduces procurement costs, simplifies operations (without the need for complex X-ray knowledge), and meets national safety standards. 4. Expansion of application fields for X-ray irradiation equipment (1) Biology and Medicine Cell research: inducing gene mutations, cell cycle regulation, signal transduction analysis. Tumor research: irradiation of tumor cell models to explore apoptosis mechanisms or radiation sensitivity. Preclinical studies: Whole body irradiation of small animals (such as mice) for research on hematopoietic system, immune response, etc. (2) Materials and Environmental Science Nanomaterial modification: changing the crystal structure or surface properties of materials through irradiation. Food quarantine: Non destructive detection of foreign objects, residual preservatives, or microbial inactivation. Nuclear waste disposal: Assist in analyzing the distribution of radioactive materials to ensure safe disposal. (3) Agriculture and Breeding Mutation breeding: Irradiating plant seeds or insects to accelerate gene mutations and screen for superior traits. 5. Development trends and challenges of X-ray irradiation equipment (1) Technical upgrade direction Intelligence: Combining AI algorithms to optimize dose distribution and experimental design. Safety: Reduce environmental radiation leakage and improve protection standards. Multi functional integration: such as integrating CT imaging and irradiation functions to achieve "detection processing" integration. (2) Industry challenges High precision dose control and stability require continuous optimization. More basic data is needed to support the differences in radiation sensitivity among biological samples. Overall, X-ray irradiation equipment is an indispensable tool in scientific research and industry. The X-ray irradiation equipment produced by Dandong Tongda Technology Co., Ltd. achieves a balance between performance and cost and is widely used in multiple fields. In the future, with technological iteration, its application scope will further expand to cutting-edge directions such as precision medicine and new material research and development.

The TDM-20 desktop X-ray diffractometer is a compact desktop device mainly used for material phase analysis and crystal structure research. 1. The core functions of TDM-20 desktop X-ray diffractometer Phase analysis of TDM-20: TDM-20 can perform qualitative/quantitative analysis on polycrystalline samples such as powders, solids, and paste materials. Crystal structure analysis of TDM-20: Based on the principle of X-ray diffraction, TDM-20 supports the analysis of crystal structures of metal samples, minerals, compounds, etc. 2. Technical characteristics of TDM-20 desktop X-ray diffractometer The high power and performance of TDM-20: using high-frequency high-voltage power supply, the power is increased to 1600W. Equipped with new high-speed array detectors or proportional detectors to improve data acquisition efficiency and accuracy. Convenient operation of TDM-20: The device is small in size and light in weight, suitable for compact laboratory spaces; Supports fast calibration and testing, with simple circuit control and easy installation and debugging. The accuracy and stability of TDM-20: the angle repeatability is as high as 0.0001 °, and the full spectrum diffraction angle linearity is ± 0.01 °. Scalability of TDM-20: TDM-20 can be equipped with a 6-digit automatic sample changer, a rotating sample stage, a low-temperature cooling system, and in-situ high/medium low temperature accessories to meet diverse testing needs. 3. Application scenarios of TDM-20 desktop X-ray diffractometer The research fields of TDM-20 include crystal structure characterization and phase transition analysis in materials science, geology, and pharmaceutical research. Industrial applications of TDM-20: pharmaceutical industry drug consistency assessment, mineral identification, petrochemical catalyst analysis, food safety testing (such as crystal composition determination). Education and National Defense of TDM-20: Rapid Phase Identification in University Teaching Experiments and National Defense Material Development. 4. Manufacturers and accessories of TDM-20 Manufacturer: Dandong Tongda Technology Co., Ltd. Optional accessories: one-dimensional array detector, proportional detector, 6-digit automatic sample changer, rotating sample stage, graphite bent crystal monochromator, etc. Overall, TDM-20, with its high power, high precision, and compact design, has become an efficient tool for laboratory phase analysis and is widely used in scientific research, industry, and teaching fields.

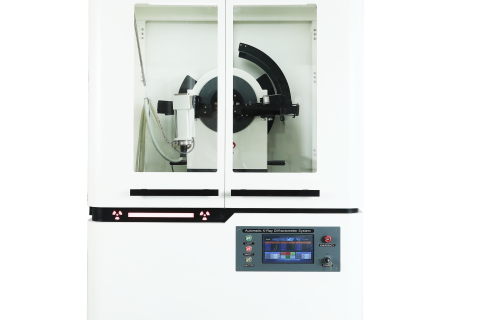

The TD-3500X-ray diffractometer (TD-3500XRD) is a high-performance analytical instrument produced by Dandong Tongda Technology Co., Ltd. It is mainly used for the analysis of crystal structure, phase composition, and material properties. 1. Core technical parameters of TD-3500X-ray diffractometer The X-ray source of TD-3500 diffractometer: Provide Cu K α or Mo K α target material selection, with adjustable tube voltage range of 10~60kV and tube current range of 2~80mA, supporting high-frequency and high-voltage solid-state generators or power frequency generators. Equipped with an imported Siemens PLC control system, it achieves automated light gate switching, tube pressure/flow regulation, and X-ray tube training functions with high stability. Angle measurement system of TD-3500X-ray diffractometer: Adopting a θ -2 θ vertical structure with a diffraction circle radius of 185mm (adjustable to 285mm), it supports testing of liquid, sol, powder, and block samples. The angular resolution reaches 0.0001 degrees, the step accuracy is 0.0001 degrees, and the angle measurement range is -5 °~165 ° (2 θ), suitable for high-precision crystal analysis. Detector of TD-3500X-ray diffractometer: Optional proportional detector (PC) or scintillation detector (SC), with a counting linear range of ≥ 700000 cps and background noise ≤ 1cps. Equipped with dual crystal monochromator technology, effectively suppressing the K α 2 component and improving the monochromaticity of the radiation. Control and software of TD-3500X-ray diffractometer: A human-machine interaction system based on imported PLC and true color touch screen, supporting parameter setting, real-time monitoring, and fault diagnosis. The software has functions such as phase diagram matching, stress analysis, and grain size calculation, and can generate standardized reports. 2. Technical characteristics and advantages of TD-3500X-ray diffractometer High precision and stability of TD-3500X-ray diffractometer: The angle measuring instrument adopts imported high-precision bearings and a fully closed-loop servo drive system, with automatic correction of motion errors and repeatability better than 0.0006 °. PLC modular design has strong anti-interference ability, supports long-term fault free operation, and can expand multiple functional accessories. Safety and protection of TD-3500X-ray diffractometer: The electronic lead door interlocking device achieves dual protection, with the light gate and lead door interlocked to ensure safe operation. Equipped with a circulating water cooling system (split or integrated), it automatically controls the water temperature and monitors the temperature of the X-ray tube to avoid blockage. Intelligent operation of TD-3500X-ray diffractometer: The touch screen displays the instrument status in real-time, supports parameter settings (such as scanning range, step size, sampling time), and remote fault diagnosis. Preset scanning modes (θ -2 θ, single crystal diffraction, thin film analysis) to meet different sample requirements. 3. The main application areas of TD-3500X-ray diffractometer Material analysis of TD-3500X-ray diffractometer: Qualitative/quantitative analysis of phases, identification of crystal structure, determination of grain size and crystallinity. Phase composition and stress analysis of materials such as semiconductors, ceramics, metals, polymers, etc. Research experiment of TD-3500X-ray diffractometer: Analysis of film orientation, phase transition research of catalyst/battery materials, and characterization of nano material structures. Biological crystals, macroscopic/microscopic stress measurement, and material temperature evolution analysis (requiring the use of a thermal analyzer). Typical user case of TD-3500X-ray diffractometer: Wuhan University of Technology (New Material Structure Research), Beijing Institute of Technology (Oxide Semiconductor Phase Transformation Research), Tongji University (Titanium Alloy Structure Analysis), etc. 4. Key points for operation and maintenance of TD-3500X-ray diffractometer Operation process of TD-3500X-ray diffractometer: Start up and preheat for 10-15 minutes → Sample preparation and fixation → Set scanning parameters (such as 2 θ range, step width, tube pressure/flow) → Start scanning → Data analysis. Support the combination of SEM and EDS to achieve comprehensive characterization of micro/nano structures and components. Widely used in materials science, chemistry, physics and other fields, it is the preferred tool for crystal structure and phase analysis.

The TD-3700 X-ray diffractometer is a high-performance and high-resolution X-ray analysis device, characterized by fast analysis, convenient operation, and strong safety. 1. Technical characteristics of TD-3700 X-ray diffractometer (1) Core configuration of X-ray diffractometer Equipped with a high-speed one-dimensional array detectoror SDD detector, using mixed photon counting technology, there is no noise interference, and the data acquisition speed far exceeds traditional scintillation detectors (with a speed increase of more than a hundred times), and it has high dynamic range (24 bits) and excellent energy resolution (687 ± 5 eV). Equipped with an imported programmable logic controller (PLC), it achieves automated control, low failure rate, strong anti-interference ability, and ensures stable operation of the high-voltage power supply for X-ray tubes. (2) Angle measuring system of X-ray diffractometer Adopting a θ/θ vertical angle measuring instrument structure, the sample is placed horizontally and supports testing of various forms of samples such as liquid, sol, powder, and block, to avoid samples falling into the bearing and causing corrosion. The scanning range of 2 θ angle is -110 °~161 °, with a minimum step of 0.0001 °, a repeatability of ± 0.0001 °, and an angle linearity of ± 0.01 °, suitable for high-precision structural analysis. Supports both conventional reflection mode and transmission mode, with the latter having higher resolution and suitable for trace samples (such as powders with low yields) and structural analysis. (3) The X-ray generation system of X-ray diffractometer The rated power can be selected from 3kW or 5kW, with a tube voltage range of 10~60 kV, a tube current of 2~80 mA, and a stability of ≤ 0.005%. Standard Cr/Co/Cu target material, suitable for different material analysis requirements. 2. Software and Control of TD-3700X-ray Diffraction Instrument (1) Control software for X-ray diffractometer Full Chinese interface, supports Windows XP system, can automatically regulate tube pressure, tube flow, and light switch, with X-ray tube aging training function. The application software provides processing functions such as peak searching, background subtraction, K α 2 stripping, integration calculation, spectrum comparison, etc. It supports inserting text annotations and various scaling operations. (2) Operation safety of X-ray diffractometer Dual protection system (linkage of light gate and lead gate), X-ray leakage rate ≤ 0.1 μ Sv/h, in compliance with national standards. Equipped with a circulating refrigeration system (split or integrated), automatic temperature control and monitoring of water flow rate, refrigerant pressure, etc., to avoid X-ray tube blockage. 3. Application scenarios of TD-3700X-ray diffractometer (1) The core function of X-ray diffractometer Qualitative/quantitative analysis of phases, analysis of crystal structure, determination of grain size and crystallinity. Macroscopic/microscopic stress detection, material orientation analysis (such as thin films, bulk samples). (2) Applicable fields of X-ray diffractometer Materials Science: Ceramics, Metals, Polymers, Superconducting Materials, etc. Environment and Geology: Soil, Rock, Mineral Analysis, and Petroleum Logging. Chemical and Pharmaceutical: Identification of Pharmaceutical Ingredients, Crystallinity Testing of Chemical Products. Other: food inspection, electronic materials, magnetic materials, etc. 4. Product advantages of TD-3700X-ray diffractometer (1) Modular design: The hardware system is modular and supports multiple accessories (such as optical accessories and special function software) that are plug and play, without the need to manually adjust the optical path. (2) Efficient and safe balance: One click operation simplifies the process, while reducing the risk of failure through PLC control, protection system, and automatic alarm functions (such as overcurrent protection and overtemperature warning). (3) Localization breakthrough: The TD series is the only XRD equipment in China that uses programmable controller technology, with performance comparable to imported models (such as D8 ADVANCE) and significantly reduced failure rates. The TD-3700X-ray diffractometer is a powerful and widely used X-ray diffractometer. Its high-performance detector, precise angle measuring system, powerful software functions, and wide range of application fields make it an important tool in scientific research and industrial production.

Special corrugated ceramic tubes, metal ceramic tubes, and glass tubes for analytical instruments, suitable for various models of XRD, XRF, crystal analyzers, and orientation instruments at home and abroad. An X-ray tube is a vacuum electronic device that generates X-rays by high-speed electron impact on a metal target material. Its structure, principle, and application involve various technical characteristics. 1. Basic structure of X-ray tube (1) Cathode (electron emission source) Composed of tungsten filament, X-ray tube heats up and emits electrons after being powered on, and is wrapped around a focusing cover (cathode head) to control the direction of the electron beam. The filament temperature is about 2000K, and the electron emission is regulated by current. (2) Anode (target material) Usually high melting point metals (such as tungsten, molybdenum, rhodium, etc.) are used to withstand high-energy electron bombardment and generate X-rays. Contains anode head (target surface), anode cap, glass ring, and anode handle, responsible for heat dissipation (through radiation or conduction) and absorption of secondary electrons. (3) Vacuum shell and window Glass or ceramic shell maintains a high vacuum environment (not less than 10 ⁻⁴ Pa) to avoid electron scattering. Window materials require low X-ray absorption, commonly using beryllium sheets, aluminum, or Lindemann glass. 2. Working principle of X-ray tube (1) Electron Acceleration and Impact The electrons emitted by the cathode filament are accelerated by high voltage (in the range of kilovolts to megavolts) and collide with the anode target material. The process of converting electronic kinetic energy into X-rays includes: Bremsstrahlung: Continuous spectrum X-rays released when electrons decelerate or deflect. Characteristic radiation: X-rays (such as Kα and Kβ lines) released by electron transitions in the inner layer of the target material. (2) Energy Conversion and Efficiency Only about 1% of the electron energy is converted into X-rays, and the remaining is dissipated in the form of heat, requiring forced cooling (such as a rotating anode design). 3. Classification and application scenarios of X-ray tubes (1) By generating electronic means Inflatable tube: an early type that relies on gas ionization to generate electrons, with low power and short lifespan (now obsolete). Vacuum tube: Modern mainstream, high vacuum environment improves electronic efficiency and stability. (2) By purpose In the medical field, diagnostic (such as dental and breast examinations) and therapeutic (such as radiotherapy) X-ray tube often use rotating anodes to increase power density. Industrial testing: non-destructive testing, material structure analysis, etc., with a focus on high penetration (hard X-rays). (3) According to the cooling method Fixed anode: simple structure, suitable for low-power scenarios. Rotating anode: The target surface rotates at high speed (up to 10000 revolutions per minute) to improve heat dissipation and support high-power output. 4. Performance characteristics and limitations of X-ray tubes (1) Advantages Low cost, small size, easy operation, suitable for routine medical and industrial testing. Flexible adjustment of target materials (such as tungsten, molybdenum, copper) to meet different energy requirements. (2) Limitations Poor brightness and collimation, large X-ray divergence angle, requiring additional collimators. The energy spectrum is continuous and contains characteristic lines, requiring filtering or monochromatization (such as using nickel filters to remove Kβ lines). 5. Comparison between X-ray tubes and synchrotron radiation sources (1) Brightness and flux X-ray tube: Low brightness, suitable for routine testing. Synchrotron radiation light source: with a brightness 106~1012times higher, suitable for cutting-edge research such as nanoimaging and protein crystallography. (2) Spectral characteristics X-ray tube: Discrete characteristic lines+continuous spectrum, energy range limited by acceleration voltage. Synchrotron radiation: wide continuous spectrum (from infrared to hard X-rays), precisely tunable. (3) Time characteristics X-ray tube: Continuous or microsecond level pulses (rotating target). Synchrotron radiation: Femtosecond level pulses, suitable for studying dynamic processes such as chemical reactions. 6. Technical parameters of X-ray tube (1) Optional target material types: Cu, Co, Fe, Cr, Mo, Ti, W, etc (2) Focus type: 0.2 × 12mm2 or 1 × 10mm2 or 0.4 × 14mm2 (fine focus) (3) Larger output power: 2.4kW or 2.7kW Overall, X-ray tube dominate in fields such as medical diagnosis and industrial testing due to their practicality and economy, but are limited by performance bottlenecks. For scenes that require high resolution and high brightness (such as cutting-edge scientific research), advanced technologies such as synchrotron radiation sources need to be relied upon. Future development directions include improving energy conversion efficiency, optimizing heat dissipation structures, and developing miniaturized X-ray sources.

Dandong Tongda's Parallel Optical Film Measuring Accessory is a specialized component for X-ray diffractometers, significantly improving thin-film sample testing performance. Its elongated grating design effectively suppresses scattering interference, enhancing signal clarity for ultra-thin and nanomultilayer films. The accessory supports small-angle diffraction analysis (0°–5°), enabling precise measurement of film thickness and interface structures. Compatible with TD-3500, TD-5000, TD-3700, and TDM-20 diffractometers, it ensures consistent performance across platforms. Widely applied in semiconductor inspection, optical coating evaluation, and new energy material research, this tool addresses challenges like weak signals and background noise. As nanomaterials and semiconductor industries advance, the accessory is poised to play an increasingly critical role in cutting-edge research and quality control.

XRD and FTIR fiber accessories provide complete material characterization solutions. XRD units analyze crystal structure and orientation, while FTIR systems identify composition through micro-imaging and ATR technology. Accessories include small-angle diffraction, parallel beam thin-film, and in-situ temperature stages for nanoscale analysis. Automated sample handling enhances efficiency. Applications span material research, industrial quality control, and scientific studies of polymer dichroism. These tools continue to evolve, driving innovations in fiber science and industrial applications.

X-ray absorption fine structure spectrometer (XAFS) is a powerful tool for studying the local atomic or electronic structure of materials, widely used in popular fields such as catalysis, energy, and nanotechnology. The basic principle of X-ray absorption fine structure spectrometer (XAFS) is that when the energy of X-rays resonates with the energy of an inner electron shell of an element in the sample, a sudden increase in electrons is excited to form a continuous spectrum, which is called the absorption edge. Near the absorption edge, as the X-ray energy increases, the absorption rate monotonically decreases as the penetration depth of the X-ray increases. When the spectrum is extended beyond a specific edge, fine structures can be observed, where X-ray absorption near edge structures (XANES) regions appear as soon as peaks and shoulders with a width exceeding 20 to 30 electron volts pass through the starting point of the edge. The fine structure located on the high-energy side of the edge where energy decays to several hundred electron volts is called X-ray Absorption Fine Structure (XAFS). The main features of X-ray absorption fine structure spectrometer (XAFS) are: Sensitivity to short-range ordering: It depends on short-range ordering and does not rely on long-range ordering, making it possible to measure a wide range of samples. It can be used for amorphous, liquid, molten, catalyst active centers, metal proteins, etc., as well as for structural studies of impurity atoms in crystals. Strong elemental characteristics: The X-ray absorption edge has elemental characteristics, and for atoms of different elements in the sample, the atomic neighbor structure of different elements in the same compound can be studied by adjusting the incident X-ray energy. High sensitivity: Fluorescence method can be used to measure samples of elements with concentrations as low as one millionth. Comprehensive acquisition of structural information: able to provide parameters that determine the local structure, such as the distance between absorbing atoms and neighboring atoms, the number and type of these atoms, and the oxidation state of absorbing elements. Sample preparation is simple: no single crystal is required, and under the experimental conditions, the data collection time is relatively short. Using a synchrotron X-ray source usually only takes a few minutes to measure a spectral line. The main advantages of X-ray absorption fine structure spectrometer (XAFS) are: Core advantage: highest luminous flux product Photon flux exceeding 1000000 photons/second/eV, with spectral efficiency several times higher than other products; Obtain data quality equivalent to synchrotron radiation Excellent stability: The stability of monochromatic light intensity of the light source is better than 0.1%, and the energy drift during repeated collection is less than 50 meV 1% detection limit: High luminous flux, excellent optical path optimization, and excellent light source stability ensure that high-quality EXAFS data can still be obtained when the measured element content is>1%. 4. Application areas of X-ray absorption fine structure spectrometer (XAFS) : Energy field: such as research on lithium batteries and other secondary battery materials, fuel cell research, hydrogen storage material research, etc. XAFS can be used to obtain the concentration, valence state, coordination environment, and dynamic changes of core atoms during charge discharge cycles and electrochemical reactions. Catalysis field: used for research on nanoparticle catalysis, single atom catalysis, etc. Obtain the morphology of the catalyst on the support, the interaction form with the support, and its changes during the catalytic process through XAFS, as well as the neighboring structures of metal ions with extremely low content. In the field of materials science, X-ray absorption fine structure spectrometer (XAFS) is used for the characterization of various materials, the study of complex systems and disordered structural materials, the research of radioactive isotopes, the study of related properties of surface and interface materials, and the study of dynamic changes in materials. In the field of geology, X-ray absorption fine structure spectrometer (XAFS) can be used for element valence state analysis of ore materials in geological research. Environmental field: XES can be used for valence state analysis of Cr/As elements, etc. In the field of radiochemistry, X-ray absorption fine structure spectrometer (XAFS) can be used for valence state analysis of Ce, U elements, etc. The X-ray absorption fine structure spectrometer (XAFS) plays an important role in modern scientific research due to its unique working principle, significant characteristics, and wide application fields. It provides a powerful means for people to gain a deeper understanding of the microstructure and chemical state of matter, promoting the development and progress of multiple disciplinary fields.

The main purpose of NDT portable X-ray welding testing machine is to inspect the processing and welding quality of materials and components such as ship hulls, pipelines, high-pressure vessels, boilers, aircraft, vehicles, and bridges in industrial sectors such as national defense, shipbuilding, petroleum, chemical, mechanical, aerospace, and construction, as well as internal defects and the inherent quality of various light metals, rubber, ceramics, etc. The principle and application of NDT portable X-ray welding testing machine: NDT portable X-ray welding testing machine utilize the acoustic, optical, magnetic, and electrical properties of materials to detect the presence of defects or unevenness in the tested object without damaging or affecting its performance. They provide information such as defect size, location, nature, and quantity. Compared with destructive testing,it has the following characteristics. The first is non-destructive, as it does not compromise the performance of the detected object during testing; The second is comprehensive, as the detection is non-destructive, it is necessary to conduct a 100% comprehensive detection of the tested object, which cannot be achieved by destructive detection; The third is comprehensive, and destructive testing is generally only applicable to the testing of raw materials, such as tension, compression, bending, etc. commonly used in mechanical engineering. Destructive testing is carried out on manufacturing raw materials, and for finished products and in use items, destructive testing cannot be carried out unless they are not intended to continue to serve.on the other hand, it does not damage the performance of the tested object. So,it can not only perform full process testing on manufacturing raw materials, intermediate processes, and even final products, but also test equipment in service. Characteristics of NDT portable X-ray welding testing machine: The X-ray generator has a small volume, with an anode grounded and forced cooling by a fan; ◆ Lightweight, easy to carry, and simple to operate; Work and rest in a 1:1 ratio; Beautiful appearance and reasonable structure; ◆ Delayed exposure to ensure operator safety; Visual inspection range of NDT portable X-ray welding testing machine 1. Inspection of surface defects on welds. Check the welding quality such as surface cracks, incomplete penetration, and leakage of the weld seam. 2. Status check. Check for surface cracks, peeling, pulling, scratches, dents, protrusions, spots, corrosion, and other defects. 3. Internal cavity inspection. When certain products (such as worm gear pumps, engines, etc.) are working, perform endoscopic testing according to the specified technical requirements. 4. Assembly inspection. When there are requirements and needs, use the same 3D industrial video endoscope to inspect the assembly quality; After assembly or a certain process is completed, check each component.Whether the assembly position of the components meets the requirements of the drawings or technical specifications; Is there an assembly defect. 5. Excess item inspection. Check for residual debris, foreign objects, and other debris inside the product cavity.

The WBK-01 X-ray irradiator generates high-energy X-rays to irradiate cells or small animals. X-ray irradiator is used for various basic and applied research. Throughout history, radioactive isotope irradiators have been used, which require transporting samples to a core irradiation facility. Today, smaller, safer, simpler, and lower cost X-ray irradiator can be installed in laboratories for convenient and rapid irradiation of cells. Various samples can be directly irradiated in the laboratory without affecting fertility or safety. The X-ray irradiator is easy to use for personnel without professional X-ray training, and there are no expensive license applications or safety or radiation source maintenance costs. This device is easy to operate, safe, reliable, and cost-effective, and can replace radioactive isotope sources. 1. Principle of X-ray irradiator: The X-ray tube in the X-ray irradiator generates high-energy electrons, which produce X-rays when they collide with the target material (usually tungsten). Accelerating electrons through a high-voltage electric field to obtain sufficient energy to generate the required X-ray wavelength and intensity. Then, the X-rays are adjusted and optimized through a series of collimators, filters, and other devices, and finally irradiated onto the sample. The main components of an X-ray irradiator are: The X-ray irradiator mainly includes X-ray tubes, high-voltage generators, control circuits, cooling systems, safety protection devices, and sample rooms. Among them, the X-ray tube is the core component responsible for generating X-rays; The high-voltage generator provides the required high voltage and current for the X-ray tube; The control circuit is used to control parameters such as the generation, intensity, and irradiation time of X-rays; The cooling system ensures that the equipment will not be damaged due to overheating during operation; The safety protection device ensures the safety of operators and the usage environment. 3. Application areas of X-ray irradiator: The X-ray irradiator can be used in the field of biology: it can be used for cell culture and division inhibition research, gene change induction, stem cell research, small animal irradiation, T-B cell research, blood cell research, bone marrow transplantation irradiation, transplantation immunity, immunosuppressive therapy, radiation sensitivity research, DNA damage research, etc. The X-ray irradiator can be used in the medical field: in tumor treatment, it can be used to locally irradiate the tumor site, kill cancer cells or inhibit their growth; The X-ray irradiator can also be used as an auxiliary diagnosis for certain diseases, such as helping to determine the condition by observing the imaging changes of tissues and organs through X-rays. The X-ray irradiator can be used in the food industry: it can be used for food irradiation preservation, killing microorganisms in food through X-ray irradiation, inhibiting enzyme activity, thereby extending the shelf life of food while maintaining its original taste and nutritional content. The X-ray irradiator can be used in the industrial field: it can be used for material performance testing and modification, such as cross-linking treatment of polymer materials to improve their strength and stability; It can also be used for non-destructive testing to detect defects and cracks inside materials. In summary, X-ray irradiator is an important scientific and industrial device with broad application prospects and value.