- Home

- >

News

A single-crystal X-ray diffractometer reveals 3D atomic structure by analyzing X-ray diffraction patterns (Bragg's Law). Through data collection, Fourier transformation, and model refinement, it generates electron density maps to determine molecular configurations.

A quality single crystal for X-ray diffraction requires optimal solvent choice (moderate solubility/volatility), proper growth method (evaporation/diffusion), high sample purity, and a vibration-free environment to ensure well-defined morphology and minimal defects.

This article details a comprehensive three-pronged strategy to eliminate higher-order diffraction interference in X-ray single-crystal analysis. The methods involve hardware filtration at the source using monochromators and slits, parameter optimization during data collection to suppress detection, and software correction algorithms for residual effects in data processing. This combined approach ensures high-precision crystal structure determination by controlling intensity errors.

The TD-5000 X-ray single crystal diffractometer is mainly used to determine the three-dimensional spatial structure and electron cloud density of crystalline substances such as inorganic, organic, and metal complexes, and to analyze the structure of special materials such as twinning, non commensurate crystals, quasicrystals, etc. Determine the accurate three-dimensional space (including bond length, bond angle, configuration, conformation, and even bonding electron density) of new compound (crystalline) molecules and the actual arrangement of molecules in the lattice; It can provide information on the crystal cell parameters, space group, crystal molecular structure, intermolecular hydrogen bonding and weak interactions, as well as structural information such as molecular configuration and conformation. X-ray single crystal diffractometer is widely used in analytical research in chemical crystallography, molecular biology, pharmacology, mineralogy, and materials science. Single crystal XRD is a high-tech product under the National Major Scientific Instrument and Equipment Development Project of the Ministry of Science and Technology, led by Dandong Tongda Technology Co., Ltd., filling the gap in the development and production of single crystal x-ray diffractometer in China.

X-ray single crystal diffractometer is mainly used to determine the three-dimensional spatial structure and electron cloud density of crystalline substances such as inorganic,organic,and metal complexes,and to analyze the structure of special materials such as twinning, non commensurate crystals,quasicrystals,etc.Determine the accurate three-dimensional space (including bond length, bond angle,configuration,conformation,and even bonding electron density) of new compound (crystalline) molecules and the actual arrangement of molecules in the lattice;Single crystal X-ray diffractometer can provide information on the crystal cell parameters,space group,molecular structure,intermolecular hydrogen bonding and weak interactions,as well as structural information such as molecular configuration and conformation.Single crystal XRD is widely used in analytical research in chemical crystallography,molecular biology,pharmacology,mineralogy,and materials science. Single crystal XRD has high precision: 2θ angle repeatability accuracy: 0.0001°; Minimum step angle: 0.0001°; Temperature control range:100K-300K Control accuracy: ±0.3K Single crystal angle measuring instrument selects four concentric scanning circles. Single crystal XRD adopts low-temperature configuration. The company's technical personnel have completed the installation and debugging of the foreign single crystal X-ray diffractometer,and the test results have greatly satisfied foreign users. At the same time,the functionality,stability,and after-sales service of the instrument have received unanimous praise from foreign users. Overall, X-ray single crystal diffractometer plays an irreplaceable role as an important scientific instrument in research and application in multiple disciplines. With the continuous advancement and innovation of technology, we believe that in the future,single crystal XRD will demonstrate their unique value and potential in more fields.

The TD-5000 X-ray single crystal diffractometer is mainly used to determine the three-dimensional spatial structure and electron cloud density of crystalline substances such as inorganic, organic, and metal complexes, and to analyze the structure of special materials such as twinning, non commensurate crystals, quasicrystals, etc. Determine the accurate three-dimensional space (including bond length, bond angle, configuration, conformation, and even bonding electron density) of new compound (crystalline) molecules and the actual arrangement of molecules in the lattice; Single crystal X-ray diffractometer can provide information on crystal cell parameters, space group, crystal molecular structure, intermolecular hydrogen bonding and weak interactions, as well as structural information such as molecular configuration and conformation. Single crystal XRD is widely used in analytical research in chemical crystallography, molecular biology, pharmacology, mineralogy, and materials science. The single crystal diffractometer adopts the four circle concentricity technique to ensure that the center of the angle measuring instrument remains unchanged regardless of the rotation, achieving the goal of obtaining the most accurate data and obtaining higher integrity. Four circle concentricity is a necessary condition for conventional single crystal scanning. The company's technical personnel have completed the installation and debugging of the foreign single crystal X-ray diffractometer, and the test results have greatly satisfied foreign users. At the same time, the functionality, stability, and after-sales service of the instrument have received unanimous praise from foreign users.

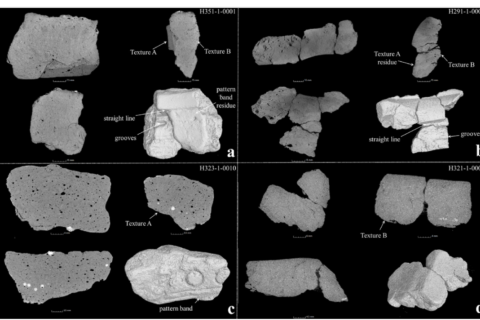

Micro-ct technology has significant advantages in the characterization of ceramics, which can reveal the composite structure inside the material without damage, and restore the key technology in the production of ceramics.