Thin Film Diffraction

thin film attachment enables precise XRD analysis of nanometer/micrometer films, ideal for semiconductors, coatings and polymers. It enhances signal, reduces substrate interference and supports high-speed scanning, widely used in R&D and quality control with TD series diffractometers.

- Tongda

- Liaoning, China

- 1—2 months

- 100 units per year

- Information

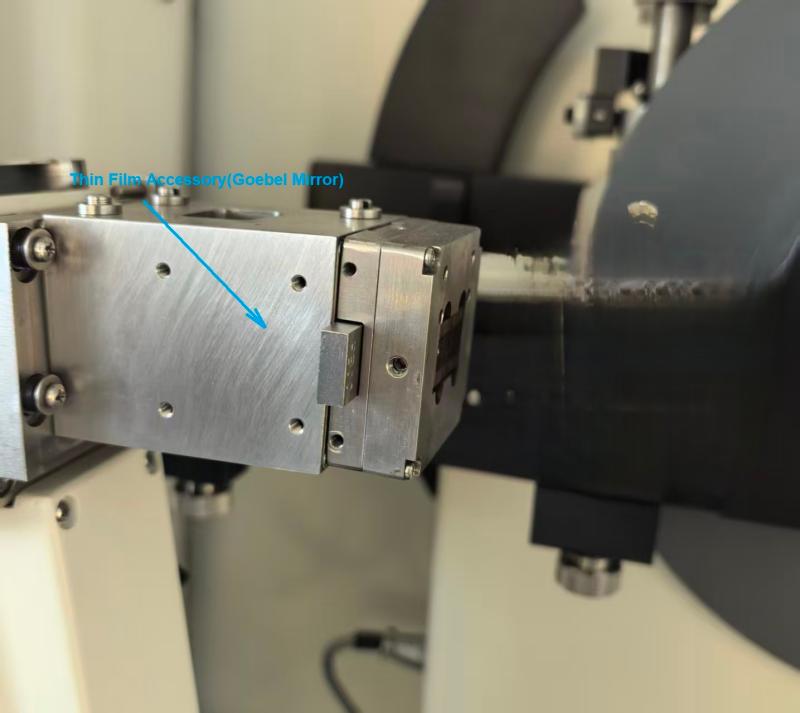

Introduction to Thin Film Attachment

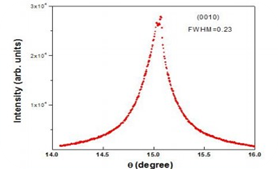

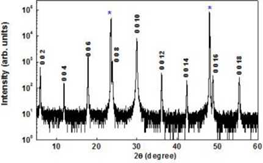

X-ray testing techniques are widely employed in the characterization of various thin film materials. Thin film materials differ from conventional powder XRD analysis due to their structural particularities and limitations. For instance, when a thin film exhibits strong preferred orientation, only diffraction signals from specific crystal planes can be observed, making characterization significantly more challenging compared to powder samples. The thin film attachment enhances characterization accuracy by incorporating longer collimator slits to effectively filter scattered radiation, reduce substrate interference, and intensify the diffraction signal from the thin film itself. Specifically designed to address low signal intensity and high background noise in thin film materials, this attachment is suitable for analyzing samples with thicknesses ranging from nanometers to micrometers.

Applications of Thin Film Attachment

The thin film attachment serves as a standard tool for semiconductor material characterization and is extensively used in R&D and quality control across materials science, nanotechnology, and semiconductor materials and devices. It is suitable for testing various thin film samples, particularly for structural analysis of epitaxial thin films and single crystal wafers, enabling phase identification, orientation degree analysis, and stress testing. Specific applications include:Metallic and Ceramic Materials: Evaluating the texture of rolled sheets, ceramic orientation, and residual stress (e.g., wear resistance and machinability analysis).

Multilayer and Functional Films: Analyzing coating structures such as magnetic films, surface-hardened metal layers, and high-temperature superconducting films, as well as interface characteristics of multilayer films on glass, silicon wafers, and metal substrates.

Polymer and Special Materials: Investigating orientation and stress in macromolecular materials like paper coatings and optical lens films.

Advantages of Thin Film Attachment

High-Efficiency Data Acquisition: Supports high-speed scanning and rapid data processing, enhancing testing efficiency and suitability for high-throughput experimental environments.

User-Friendly Operation and Stability: The attachment’s structural design simplifies calibration procedures, enabling quick sample positioning and testing. Its core components are optimized for extended service life and compatibility with mainstream equipment such as the TD series X-ray diffractometers.

Powerful and Intelligent Functionality: Integrates multiple measurement modes (e.g., transmission/reflection pole figure testing, stress analysis) and enables automated control and data analysis via software, significantly improving detection accuracy and operational intelligence.

Through technological innovation, the thin film attachment addresses key challenges in thin film material characterization and delivers a reliable solution for advanced material R&D and quality control.