TD-RSD X-ray Residual Stress Analyzer

Chinese version residual stress measurement and analysis software supports both linear and elliptical fitting methods. It employs complete stress equations without assuming zero shear stress, along with the elliptical fitting method, allowing simultaneous measurement of normal stress and shear stress values. Each measurement uses more than 9 ψ angles. Peak profile fitting includes Gaussian, Lorentzian, Pearson VII, parabolic, etc. Measurement results can simultaneously display normal stress values, shear stress values, as well as information such as peak intensity, integral width, and full width at half maximum (FWHM).

- Tongda

- Liaoning,China

- 1—2 months

- 100 units per year

- Information

Features & Performance

Power:3kW

Detectors: 2 high-speed, symmetrically arranged, fiber-optic-based solid-state detectors.

X-ray Optical Vertical Alignment Mechanism

Diffraction Geometries Dual-detector Omega (Ω) method、Dual-detector Psi (Ψ) method、Rocking Curve Method

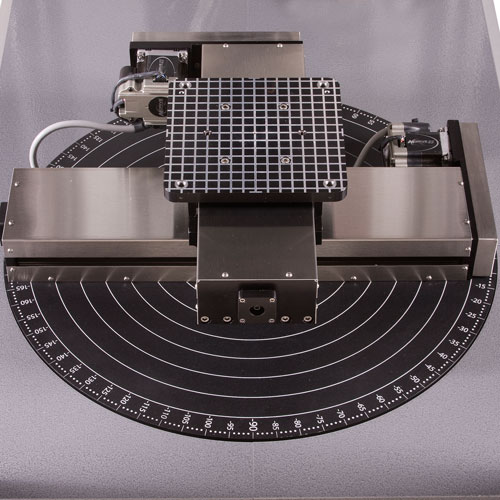

Travel of X, Y, Z Axes:240、240、500mm,ϕ - axis:360°,Stage Load Capacity: 50 kg (100 kg optional)

Dimensions: 1300 x 1400 x 1880 mm, customizable.

Software: Complete 3D stress analysis module with elliptical fitting and linear fitting capabilities, capable of analyzing stresses under nearly all complex conditions.

Measurement Accuracy & Repeatability (on Stress-Free Iron Powder):Standard deviation of stress over 5 consecutive measurements is less than ±7 MPa.

Conforms to the latest international and domestic standards, including: European Standard EN 15305:2008, American Standard ASTM E915-21, Chinese National Standard GB/T 7704-2017, and the Ministry of Industry and Information Technology Specification JJF (Mechanical) 1083-2023.

User-Friendly Software

Performs linear and elliptical fitting methods. Utilizing complete stress equations that do not assume zero shear stress, along with elliptical fitting, it measures both normal and shear stress values simultaneously, with each measurement employing over 14 ψ angles. Peak profile fitting includes Gaussian, Lorentzian, Pearson, parabolic, etc. Measurement results can simultaneously display normal and shear stress values, as well as information such as peak intensity, integral width, and full width at half maximum (FWHM).

Goniometer and Accessories:

Fully automatic computer control, compatible with both the omega (Ω) inclination method and the psi (Ψ) inclination method, and capable of simultaneous rocking curve measurement.

- Fine-focus ceramic X-ray tube, with multiple target materials optional.

- Two symmetrically arranged, high-speed, fiber-optic-based solid-state detectors.

- Manual and automatic focusing and collimation, with laser positioning.

Triaxial Sample Stage:

The automated X, Y, and ϕ axes enable the mapping of stress contours, from which the magnitude and direction of principal stresses are calculated.

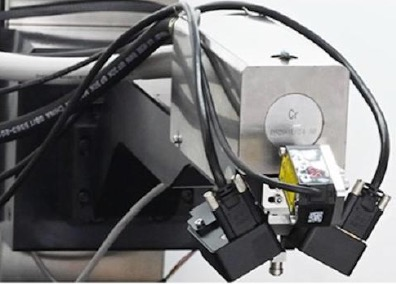

Detector:

The core component is a solid-state position-sensitive detector with an optical fiber sensor. Its length is not less than 1m, and its width is not less than 25°. The acquisition time is less than 8 seconds. It will not experience radiation saturation under prolonged X-ray exposure, has a lifespan of over 10 years, and is shock-resistant, waterproof, and moisture-proof. Options include: single-channel, linear array, and area array detectors.

X-ray Tube:

Fine-focus ceramic X-ray tube, with a built-in sealed self-circulating cooling system, meets the requirements for continuous 24-hour non-stop X-ray operation, and features automatic over-temperature protection. Multiple target materials are optional, including Cr, Cu, Mn, Co, V, Ti, Fe, Mo, etc.