News

The rotating sample holder in an X-ray diffractometer is a key component used for precise adjustment and fixation of the sample position,the sample can rotate within its own plane, which is beneficial for errors caused by coarse grains. For samples with texture and crystallography, rotating sample holder ensures good reproducibility of diffraction intensity and eliminates preferred orientation. Working principle of rotating sample holder: When the X-ray diffractometer is working, high-energy X-rays generated by the X-ray source are irradiated onto the sample fixed on the rotating sample stage. Due to the specific crystal structure and lattice parameters of the sample, X-rays will undergo scattering, absorption, and diffraction phenomena when interacting with the sample, where diffraction phenomena occur according to the requirements of the Bragg equation. The rotating sample holder can rotate at smaller angles according to the setting, allowing the sample to receive X-ray irradiation at different angles, thereby obtaining diffraction patterns at different angles. In this way, the detector can measure the X-ray intensity after sample diffraction and convert it into an electrical signal to be transmitted to the computer for data processing. The main function of the rotating sample holder is: Rotation method: β axis (sample plane) Rotation speed: 1~60RPM Small step width: 0.1 º Operation mode: Constant speed rotation for sample scanning (step, continuous) Advantages of rotating sample holder: The rotating sample holder can improve the accuracy of diffraction data: For samples with irregular powder or particle shapes, the characteristic of preferred orientation is prone to occur during conventional powder sample preparation, resulting in deviations in the distribution of diffraction intensity and affecting the accuracy of diffraction result analysis. Rotating the sample stage can move the sample in a certain form in an appropriate space, eliminating the influence of preferred orientation to a certain extent, thereby improving the accuracy of diffraction data. The rotating sample holder can adapt to various testing needs: able to adapt to different types of X-ray diffraction angle measuring instruments, such as vertical angle measuring instruments, low-power compact powder diffraction equipment, etc., providing convenience for different testing needs. And rotating sample holder can meet the requirements of various samples and testing conditions by adjusting parameters such as speed and steering. The rotating sample holder can expand the instrument's analytical capabilities: New types of rotating sample stages are constantly being developed and applied, such as some sample stages for in-situ electrochemical X-ray diffraction analysis, which can monitor and analyze the changes of materials in different environments or conditions in real time, expanding the analysis capabilities of X-ray diffraction equipment. In summary, the rotating sample holder in X-ray diffractometer is crucial for accurately obtaining crystal structure information of substances. the rotating sample holder can not only improve the accuracy of diffraction data, but also adapt to various testing needs and expand the analytical capabilities of the instrument.

In X-ray diffractometer, the multifunctional integrated measuring accessories are crucial component that greatly enhances the functionality and flexibility of the instrument. Used for the analysis of films on boards, blocks, and substrates, and can perform tests such as crystal phase detection, orientation, texture, stress, and in-plane structure of thin films. Basic overview of multifunctional integrated measuring accessories: Definition: They are general term for a series of additional devices or modules used in X-ray diffractometer to expand instrument functions, improve measurement accuracy and efficiency. Purpose: These attachments aim to enable X-ray diffractometer to meet a wider range of experimental needs and provide more comprehensive and accurate material structure information. The functional characteristics of multifunctional integrated measuring accessories: Perform polar diagram testing using transmission or reflection methods; Stress testing can be conducted using either the parallel tilt method or the same tilt method; Thin film testing (in-plane rotation of the sample). Technical characteristics of multifunctional integrated measuring accessories: High precision:They typically use advanced sensing technology and control systems to ensure high precision and repeatability of measurements. Automation: Many attachments support automated operations and can be seamlessly integrated with the X-ray diffractometer host to achieve one click measurement. Modular design: facilitates users to select and combine different accessory modules according to their actual needs. Application areas of multifunctional integrated measuring accessories: Widely used in fields such as materials science, physics, chemistry, biology, and geology; Evaluation of metal assembly structures such as rolled plates; Evaluation of ceramic orientation; Evaluation of crystal priority orientation in thin film samples; Residual stress testing of various metal and ceramic materials (evaluation of wear resistance, cutting resistance, etc.); Residual stress testing of multilayer films (evaluation of film peeling, etc.); Analysis of surface oxidation and nitride films on high-temperature superconducting materials such as thin films and metal plates; Glass Si、Analysis of multilayer films on metal substrates (magnetic thin films, metal surface hardening films, etc.); Analysis of electroplating materials such as macromolecular materials, paper, and lenses. The multifunctional integrated measuring accessories in X-ray diffractometer are the key to improving instrument performance. They not only enhance the functionality of the instrument, but also improve the accuracy and efficiency of measurement, providing researchers with more comprehensive and in-depth material analysis methods. With the continuous advancement of technology, these attachments will continue to play an important role in promoting scientific research in related fields to achieve more breakthroughs.

The high temperature accessory in a diffractometer is an additional device that can perform X-ray diffraction analysis on samples under high temperature conditions. To understand the changes in crystal structure of samples during high-temperature heating and the changes in mutual dissolution of various substances during high-temperature heating. Working principle of high temperature accessory: By using methods such as resistance heating, induction heating, or radiation heating, the sample is heated within a set temperature range. At the same time, it is equipped with high-precision temperature sensors and control systems to monitor and adjust the temperature of the sample in real time, ensuring the stability and accuracy of the temperature. The temperature control accuracy can reach ±0.5℃ or even higher. In order to maintain the stability of the sample at high temperatures and prevent it from reacting with oxygen in the air, high temperature accessory usually require an atmosphere protection system. Common atmospheres include inert gases such as argon, nitrogen, etc. The atmosphere control system can accurately control the flow rate and pressure of the atmosphere, providing a stable experimental environment for the sample. The main functions of high temperature accessory is: Real time monitoring of sample phase transition, chemical reactions, crystal structure changes, and other processes can be carried out in high-temperature environments to obtain information on the structure and properties of substances at different temperatures. By analyzing the position, intensity, and shape of diffraction peaks, the crystal cell parameters, crystal structure, phase composition, and other information of the sample can be obtained, and the content of each component can be accurately measured. Study the rate, mechanism, and diffusion behavior of chemical reactions. For example, observing the structural changes of catalysts during high-temperature reactions, understanding the formation and disappearance of their active centers, and optimizing the performance of catalysts. Application area of high temperature accessory: Used to study the phase transition, crystal structure evolution, and performance changes of high-temperature superconducting materials, metal alloys, ceramic materials, etc. at different temperatures, providing a basis for material design and preparation. Monitoring the changes in substances during chemical reactions, such as studying the structural changes of catalysts and the evolution of active centers in high-temperature catalytic reactions, can help develop efficient catalysts. Study the physical properties of substances at high temperatures, such as magnetism, electronic structure, and their relationship with temperature, and explore new physical phenomena and laws. Technical parameter of high temperature accessory: Temperature setting: Inert gas environment from room temperature to 1200 ℃ Vacuum environment: high temperature of 1600 ℃ Temperature control accuracy: ± 0.5 ℃ Window material: Polyester film Cooling method: deionized water circulation cooling In summary, the high temperature accessory in the diffractometer is an important testing tool that can perform X-ray diffraction analysis on samples under high temperature conditions, providing strong support for research in fields such as materials science, chemical engineering, and physics.

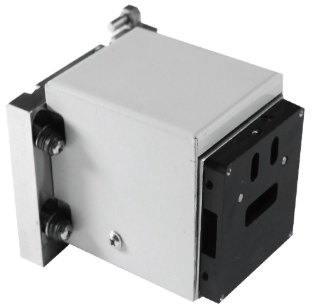

The multi-function sample holder in an X-ray diffractometer is a device used for placing and fixing samples, with multiple functions and features. It can test trace amounts of powder samples, as well as samples that are sheet-like, large-sized, irregular, cannot be cut, or ground into powder. The multi-function sample holder sample fixation and support: The sample holder can firmly fix the sample, ensuring that the sample remains stable during X-ray diffraction and preventing the accuracy and reliability of diffraction data from being affected by sample movement. The multi-function sample holder height and angle adjustment: It has the function of adjusting height and angle, and can flexibly adjust the distance and relative angle between the sample and the X-ray tube and detector according to the size, shape, and detection requirements of different samples, in order to obtain the best diffraction effect. The multi-function sample holder rotation function: Some sample tables can rotate, allowing the sample to receive X-ray irradiation at different angles, thereby obtaining more diffraction information from different angles, which helps to comprehensively analyze the crystal structure and orientation of the sample. The multi-function sample holder adaptation: It can adapt to different types of samples, such as solid, liquid, powder, etc. By replacing different sample fixtures or accessories, it can meet the testing requirements of various samples. The multi-function sample holder environmental control: Some advanced sample holders are also equipped with environmental control systems that can test samples under specific temperature, humidity, atmosphere, and other conditions to simulate the effects of different environments on samples, further expanding the application range of X-ray diffractometers. The multi-function sample holder in X-ray diffractometer is a powerful, flexible and versatile auxiliary equipment, which is of great significance for improving the accuracy and efficiency of X-ray diffraction experiments.

Parallel optical film measuring accessory is an optical component used to enhance the signal intensity of thin films and reduce the influence of substrate signals on measurement results. Usually used in optical experiments or instruments, mainly for generating parallel beams or conducting optical measurements on thin film samples. By increasing the length of the grating, more precise control and filtering of light can be achieved. When light passes through, the grating plate can filter out more scattered lines, making the transmitted light purer and more concentrated, thereby reducing the interference of scattered light on the thin film signal and enhancing the signal strength of the thin film itself, improving the accuracy and reliability of measurement. 1. Main function of parallel optical film measuring accessory Improving measurement accuracy: In thin film related detection and analysis, such as thin film thickness measurement, optical constant determination, etc., parallel light thin film attachments can effectively reduce the influence of substrate signals, making the measurement results closer to the true characteristics of the thin film, thereby improving measurement accuracy and precision. Enhance signal strength: It helps to increase the intensity of the light signal reflected or transmitted by the thin film, which is particularly important for some thin film samples with weaker signals. The enhanced signal can be more clearly received and recognized by the detector, reducing the detection limit and improving the sensitivity of the instrument for detecting thin film samples. Improving image quality: In some applications that require imaging observation of thin films, such as observing the surface morphology of thin films under a microscope, parallel light thin film attachments can reduce background noise and blurring caused by scattered light, making the image of the thin film clearer, higher contrast, and easier to observe and analyze the detailed structure of the thin film. 2. Main components of parallel optical film measuring accessory Light source: Typically, lasers, LEDs, or other monochromatic light sources are used. Collimator lens: converts divergent light beams into parallel light. Sample stand: used for placing film samples, usually adjustable in position and angle. Detector: used to receive transmitted or reflected light signals for measurement and analysis. 3. Application fields of parallel optical film measuring accessory Optical research: used to study the optical properties of thin films, such as interference, diffraction, etc. Materials Science: Used to measure the thickness and refractive index of thin films and evaluate material properties. Industrial testing: used for quality control and testing in film production. 4. Instructions for parallel optical film measuring accessory Adjust the light source: Ensure that the light source is stable and the beam is uniform. Collimated beam: Adjust the beam of light through a collimating lens to make it parallel. Place the sample: Place the film sample on the sample stage, adjust the position and angle. Measurement and analysis: Use detectors to receive light signals, record data, and perform analysis. 5. Precautions Light source stability: Ensure the stability of the light source to avoid measurement errors. Cleaning of optical components: Keep the optical components clean to avoid dust and stains affecting the measurement results. Sample preparation: Ensure that the film sample is uniform and defect free to obtain accurate measurement results. In summary, the parallel optical film measuring accessory is an important optical component that plays a crucial role in multiple fields and is of great significance in promoting scientific research and technological progress in related fields.

The medium and low temperature accessory of an X-ray diffractometer is a key component used for X-ray diffraction analysis in low-temperature environments.The medium and low temperature accessory is widely used in research and development work in materials science, physics, chemistry, and other fields, especially suitable for scenarios that require structural analysis of materials under different temperature conditions. In order to understand the changes in crystal structure during low-temperature refrigeration process, the following are the technical parameters of the medium and low temperature accessory: Vacuum environment:- 196~500℃ Temperature control accuracy: ± 0.5 ℃ Refrigeration method: liquid nitrogen (consumption less than 4L/h) Window material: Polyester film Cooling method: deionized water circulation cooling In short, the medium and low temperature accessory of X-ray diffractometer is important equipment component that can provide strong support for scientific research and material analysis.The medium and low temperature accessory of a diffractometer is one of the important tools in the field of material structure analysis, with broad application prospects and significant research value.The medium and low temperature accessory of the diffractometer is a key component to ensure the normal operation and accurate measurement of the instrument under low-temperature conditions. Its design and performance directly affect the accuracy and reliability of experimental results. When selecting and applying medium and low temperature accessory, experimental requirements, sample characteristics, as well as the technical parameters and performance characteristics of the accessories should be fully considered to ensure the best experimental results.

The X-ray irradiator generates high-energy X-rays to irradiate target objects or biological tissues. The generation of X-rays is usually achieved by accelerating electrons to collide with metal targets (such as tungsten, copper, etc.), generating bremsstrahlung and forming X-ray beams, which then irradiate cells or small animals. X-ray irradiator is used for various basic and applied research. Historically, radioactive isotope irradiators were used, which required transporting samples to a core irradiation facility. However, today, smaller, safer, simpler, and lower cost X-ray irradiator can be installed in laboratories for convenient and rapid irradiation of cells. Various samples can be directly irradiated in the laboratory without affecting fertility or safety. The X-ray irradiator is convenient for personnel who have not received professional X-ray training to use, and there are no expensive license applications or safety or radiation source maintenance costs. The X-ray irradiator is easy to operate, safe, reliable, and cost-effective, and can replace radioactive isotope sources. 1. The main application areas of X-ray irradiator include medical field, scientific research field, etc 2. Safety precautions for X-ray irradiation equipment: Radiation protection: Operators need to wear protective clothing to avoid prolonged exposure to X-rays. Equipment maintenance: Regularly inspect the equipment to ensure its normal operation and prevent radiation leakage. Dose control: Strictly control the irradiation dose to avoid unnecessary harm to the sample or human body.

The principle and application of NDT portable X-ray welding testing machine: NDT portable X-ray welding testing machine is the use of the acoustic, optical, magnetic, and electrical properties of materials to detect the presence of defects or unevenness in the tested object without damaging or affecting its performance. It provides information on the size, location, nature, and quantity of defects. Compared with destructive testing, non-destructive testing has the following characteristics. The first is non-destructive, as it does not compromise the performance of the detected object during testing; The second is comprehensive, as the detection is non-destructive, it is necessary to conduct a 100% comprehensive detection of the tested object, which cannot be achieved by destructive detection; The third is comprehensive, and destructive testing is generally only applicable to the testing of raw materials, such as tension, compression, bending, etc. commonly used in mechanical engineering. Destructive testing is carried out on manufacturing raw materials, and for finished products and in use items, destructive testing cannot be carried out unless they are not intended to continue to serve. Non destructive testing, on the other hand, does not damage the performance of the tested object. So, It can not only perform full process testing on manufacturing raw materials, intermediate processes, and even final products, but also test equipment in service. Characteristics of NDT portable X-ray welding testing machine: The X-ray generator has a small volume, with an anode grounded and forced cooling by a fan; ◆ Lightweight, easy to carry, and simple to operate; Work and rest in a 1:1 ratio; Beautiful appearance and reasonable structure; ◆ Delayed exposure to ensure operator safety; The main purpose of NDT portable X-ray welding testing machine : The main purpose of the equipment is to inspect the processing and welding quality of materials and components such as ship hulls, pipelines, high-pressure vessels, boilers, aircraft, vehicles, and bridges in industrial sectors such as national defense, shipbuilding, petroleum, chemical, mechanical, aerospace, and construction, as well as internal defects and the inherent quality of various light metals, rubber, ceramics, etc.

The X-ray crystal orienter operates based on the principle of X-ray diffraction. The high voltage generated by the high-voltage transformer acts on the X-ray tube, producing X-rays. When the X-ray is irradiated onto the sample, diffraction occurs when the Bragg diffraction condition (n λ=2dsin θ) is satisfied. Among them, λ is the wavelength of X-rays, d is the spacing between atomic planes inside the crystal, and θ is the angle between the incident X-rays and the crystal plane. The diffraction line is received by the counting tube and displayed on the microampere meter of the amplifier. When using a monochromator, the diffraction line is monochromatized and then received by the counter and displayed on the microampere meter of the amplifier, thereby improving measurement accuracy. The X-ray crystal orienter can accurately and quickly determine the cutting angle of natural and artificial single crystals (piezoelectric crystals, optical crystals, laser crystals, semiconductor crystals), and is equipped with a cutting machine for directional cutting of the above-mentioned crystals. X-ray crystal orienter is an indispensable instrument for precision machining and manufacturing of crystal devices. The X-ray crystal orienter is widely used in the research, processing, and manufacturing industries of crystal materials. The X-ray crystal orienter is easy to operate, does not require professional knowledge or skilled techniques, displays the angle digitally, is easy to observe, and reduces reading errors. The display of the X-ray crystal orientation instrument can be zeroed at any position, making it easy to display the deviation value of the chip angle. The dual angle measuring instrument can work simultaneously, improving efficiency. The X-ray crystal orienter has a special integrator with peak amplification, which improves the detection accuracy. The integration of X-ray tube and high-voltage cable increases high-voltage reliability. The detector high-voltage adopts DC high-voltage module and vacuum suction sample board, which improves the angle measurement accuracy and speed. Overall, the X-ray crystal orienter is a precision instrument based on the principle of X-ray diffraction, which provides important technical support for crystal material research and related applications by accurately measuring the cutting angle of crystals.

The Small angle diffractometer accessories are important accessories used in X-ray diffractometers. Small angle diffractometer accessories enable X-ray diffraction measurements to be taken within a very small angle range, from 0°to5°, for thickness testing of nano multilayer films. Plays an important role in fields such as materials science, physics, chemistry, and biology. Common types and characteristics: Parallel light thin film accessory: This accessory can generate parallel X-ray beams and is suitable for small angle diffraction measurements of thin film samples. It can improve the accuracy and resolution of measurements, reduce measurement errors caused by beam divergence, and better adapt to thin film samples of different thicknesses and properties. Multi functional sample stage: Equipped with small angle diffraction accessories, the multifunctional sample stage can provide various testing environments for samples, such as in-situ heating, cooling, stretching, etc. This makes it more convenient to study the structural changes of materials under different external conditions, and enables real-time observation of the structural response of materials during temperature, stress, and other changes. The Small angle diffractometer accessories play important role in multiple fields such as materials science, physics, chemistry, and biology by achieving small angle diffraction and precise measurement of nano multilayer film thickness, providing researchers with a powerful tool for in-depth exploration of material microstructures and properties.