Tips for Doubling Experimental Efficiency of Powder Diffractometers

2025-12-30 15:21As a core characterization instrument in materials science, chemistry, geology, and other fields, the experimental efficiency of a powder diffractometer directly impacts research progress. Many researchers often face issues such as prolonged experimental time and high repetition rates due to operational details, parameter settings, and other factors. Mastering the following key techniques—from sample preparation and instrument calibration to process optimization—can double experimental efficiency while ensuring data quality.

Sample preparation is the foundation for improving efficiency, requiring a balance of uniformity and suitability. First, the sample must be ground to an appropriate particle size, generally recommended between 200-400 mesh. Particles that are too coarse can lead to broadened diffraction peaks and unstable intensity, necessitating repeated testing; particles that are too fine can easily cause preferred orientation, increasing the difficulty of data correction. A planetary ball mill combined with an agate mortar can be used, adding a small amount of dispersant during grinding to prevent particle agglomeration. After grinding, sieving ensures uniform particle size. Second, sample loading must be standardized. Employ the three-step method of "leveling-compacting-smoothing" to ensure the sample surface is flush with the sample holder, reducing background noise. For small sample quantities, special sample holders can be used to minimize the amount needed, avoiding repeated loading due to insufficient sample material.

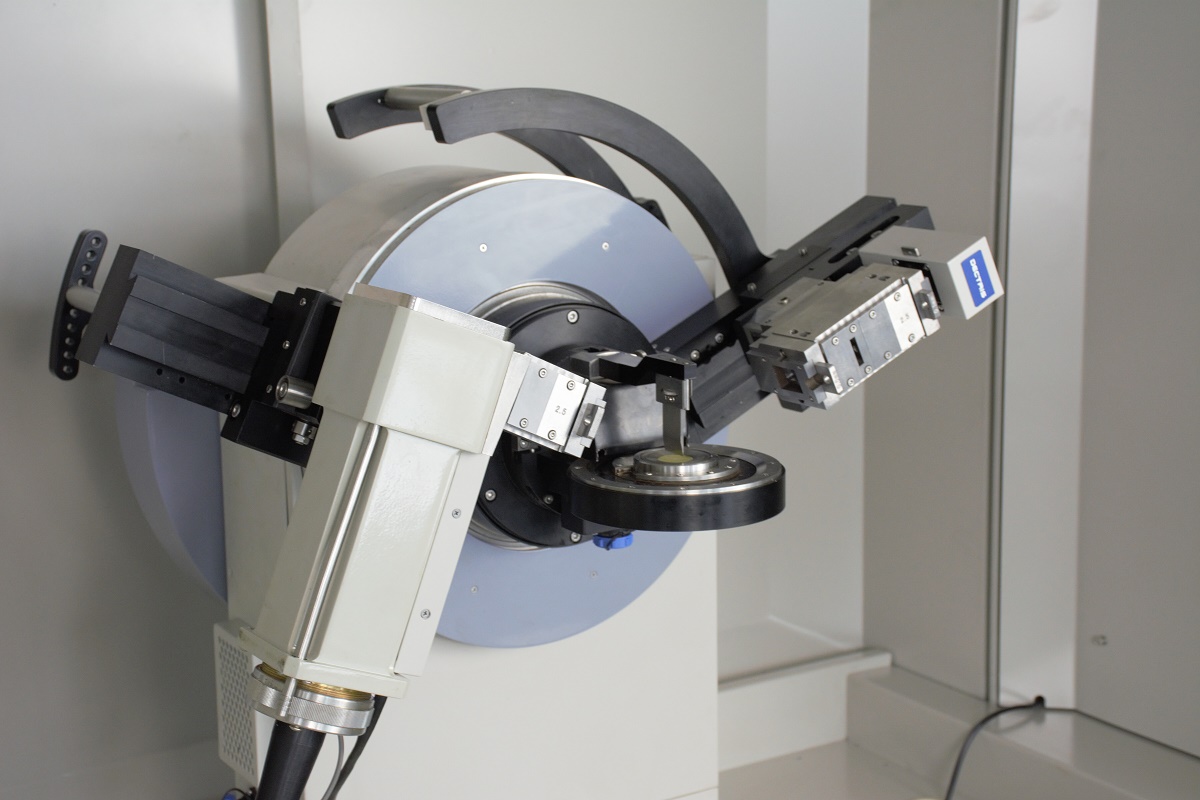

Instrument parameter optimization is the core step, requiring precise settings based on experimental objectives. The diffraction angle range (2θ) should be reasonably selected according to sample characteristics, avoiding the time-consuming practice of blindly testing the full range. For example, for routine phase analysis, the testing interval can be set based on the characteristic diffraction peak range of known samples, avoiding time wasted on scanning ineffective ranges. Scan speed and step size need to balance efficiency with data precision. For qualitative analysis, the scan speed can be appropriately increased (e.g., 4°/min) with a larger step size (e.g., 0.02°); for quantitative analysis or detailed structural characterization, it is necessary to reduce speed and use a smaller step size. Additionally, enabling the instrument's automatic peak finding and baseline correction functions can reduce manual processing time during subsequent data analysis. At the same time, the status of core components such as the X-ray tube and detector should be checked before experiments, and cooling water should be replaced regularly along with instrument calibration to avoid experimental interruptions caused by equipment failure.

Process optimization and batch processing can further enhance efficiency. Before the experiment, organize the sample sequence by grouping together samples with identical testing conditions to avoid the time loss associated with frequent parameter changes and instrument stabilization. Utilize the instrument's built-in batch testing function to pre-edit the testing sequence, setting information such as sample numbers, testing parameters, and save paths. This enables unattended continuous testing, which is particularly suitable for the centralized characterization of large sample quantities.During the data processing stage, efficiency can be improved by utilizing the batch processing functions of software such as Origin and Jade to uniformly perform operations like spectrum smoothing, background subtraction, and phase identification, replacing the manual one-by-one processing of individual samples. Furthermore, establishing experiment templates—where frequently used test parameters and data processing workflows are saved as templates—allows for direct application in subsequent experiments, reducing the time spent on repetitive setup.

Furthermore, daily maintenance and standardized operating procedures should not be overlooked. Regularly clean components such as the sample stage and detector window to prevent contaminants from affecting diffraction signals. Operators must undergo systematic training to master the instrument’s operational workflow thoroughly, thereby reducing experimental rework caused by operational errors. Through the comprehensive application of the above techniques, the experimental cycle can be significantly shortened while ensuring data reliability, achieving a doubling of the experimental efficiency of powder diffractometers.