- Home

- >

News

The crystal orientation instrument serves as a critical navigator in high-end manufacturing, enabling precise, non-destructive detection of atomic alignment in materials like silicon and sapphire. It ensures optimal cutting and processing in semiconductor and optical industries, enhancing product performance, reducing waste, and supporting automated, high-precision production.

X-ray crystal orientation analyzers are vital for developing high-performance optoelectronic materials like those in LEDs and solar cells. They enable precise control of crystal structure during growth and thin-film production, ensuring optimal quality. Essential for R&D, they bridge fundamental science and industrial manufacturing, supporting innovation in next-generation devices.

In the field of modern technology, many high-tech products—from smartphone screen substrates to core components of laser generators—rely on a fundamental material: synthetic single crystals. The precision of the cutting angle of these crystals directly determines the performance and yield of the final products. The X-Ray Orientation Analyzer is an indispensable instrument in the precision manufacturing of crystal devices. Utilizing the principle of X-ray diffraction, it accurately and rapidly measures the cutting angles of both natural and synthetic single crystals, including piezoelectric crystals, optical crystals, laser crystals, and semiconductor crystals. Dandong Tongda Science and Technology Co., Ltd. offers a range of reliable X-Ray Orientation Analyzers tailored to the research, processing, and manufacturing needs of the crystal materials industry. 01 Versatile Machine for Diverse Crystal Orientation Needs Dandong Tongda's X-Ray Orientation Analyzers primarily include models such as the TYX-200 and TYX-2H8. The TYX-200 model boasts a measurement accuracy of ±30″, with a digital display and a minimum reading of 10″. The TYX-2H8 model is an improved version of the TYX-200, featuring enhancements in the goniometer structure, load-bearing track, X-ray tube sleeve, support body, and an elevated sample stage. These improvements enable the TYX-2H8 to handle samples weighing 1–30 kg with diameters of 2–8 inches. It retains a digital angle display and a measurement accuracy of ±30″. 02 Advanced Technical Features for User-Friendly Operation Dandong Tongda's X-Ray Orientation Analyzers are designed with practicality and reliability in mind. Their user-friendly operation requires no specialized knowledge or advanced skills from the operator. The instrument features a digital angle display, ensuring intuitive and easy-to-read measurements while minimizing the risk of misreading. The display can be zeroed at any position, allowing direct reading of the wafer angle deviation. Some models are equipped with dual goniometers for simultaneous operation, significantly improving detection efficiency. A special integrator with peak amplification enhances measurement accuracy. The X-ray tube and high-voltage cable adopt an integrated design, improving high-voltage reliability. The detector high-voltage system uses a DC high-voltage module, and the vacuum suction sample stage further enhances measurement accuracy and speed. 03 Dedicated Sample Stage Designs for Various Testing Needs To meet the measurement requirements of samples with different shapes and sizes, Dandong Tongda offers a variety of specialized sample stages: TA Sample Stage: Designed for rod-shaped crystals, it features a load-bearing track and can test crystal rods weighing 1–30 kg with diameters of 2–6 inches (expandable to 8 inches). This stage can measure reference surfaces of rod-shaped crystals as well as surfaces of wafer-shaped crystals. TB Sample Stage: Also designed for rod-shaped crystals, it includes a load-bearing track and V-shaped support rails. It can test crystal rods weighing 1–30 kg, with diameters of 2–6 inches (expandable to 8 inches) and lengths of up to 500 mm. It measures end faces of rod-shaped crystals and surfaces of wafer-shaped crystals. TC Sample Stage: Primarily used for detecting the outer reference surfaces of single-crystal wafers such as silicon and sapphire. Its open-design suction plate avoids X-ray obstruction and positioning inaccuracies. The stage's suction pump securely holds wafers sized 2–8 inches, ensuring precise detection. TD Sample Stage: Designed for multi-point measurements of wafers such as silicon and sapphire. Wafers can be manually rotated on the stage (e.g., 0°, 90°, 180°, 270°) to meet specific customer measurement needs. 04 High-Performance Model for Large Sample Challenges For large and challenging sample detection, Dandong Tongda's X-Ray Orientation Analyzers demonstrate exceptional performance. The TYX-2H8 model, for example, is particularly suitable for orienting sapphire crystal ingots and rods. This instrument supports measurements of sapphire A, C, M, and R crystal orientations, with an adjustable measurement range of 0–45° via electric automation. Its technical specifications are impressive: Copper-target X-ray tube with grounded anode and forced air cooling. Adjustable tube current: 0–4 mA; tube voltage: 30 kV. Operation via computer or touchscreen control. Synchronized movement of the X-ray tube and detector; electric-driven rotary table. Total power consumption: ≤2 kW. Most notably, its sample handling capacity includes crystal ingots weighing up to 30–180 kg, with maximum dimensions of 350 mm in diameter and 480 mm in length. These capabilities make it suitable for large sample detection in most industrial scenarios. 05 Broad Applications Supporting Multiple Industries Dandong Tongda's X-Ray Orientation Analyzers are widely used across various industries involved in the research, processing, and manufacturing of crystal materials. In the semiconductor industry, they enable precise orientation cutting of silicon wafers. In the optoelectronics field, they are used for precision processing of sapphire substrates, optical crystals, and laser crystals. In the piezoelectric materials sector, they ensure accurate cutting angle measurements for stable end-product performance. The instruments are particularly well-suited for sapphire materials, which are in high demand due to their hardness, high light transmittance, and excellent physicochemical stability. Sapphire is widely used in LED substrates, consumer electronic screens, and optical windows. Dandong Tongda's X-Ray Orientation Analyzers have become essential tools in China's crystal material research and manufacturing fields, thanks to their reliable performance, diverse configurations, and strong adaptability. Their modular design and variety of sample stage options allow users to select configurations that meet specific needs, ensuring high detection accuracy while improving work efficiency. Whether for research institutions or manufacturing quality control and process optimization, these instruments provide robust technical support, empowering users to achieve breakthroughs in precision manufacturing.

Trusted Worldwide: Dandong Tongda's X-Ray Orientation Analycer Receives Multi-National Certifications In today's rapidly evolving global landscape of semiconductors, optical devices, and materials science, precise crystal orientation measurement has become crucial for enhancing product quality and production efficiency. As a specialized developer and manufacturer in the field of X-ray analysis instruments, Dandong Tongda Technology Co., Ltd. announces the launch of its high-performance X-Ray Orientation Analyzer. This instrument integrates advanced X-ray diffraction technology with intelligent algorithms, delivering fast and accurate orientation measurement solutions for crystal-related industries worldwide. Technical Principle: The Perfect Integration of X-Ray Diffraction and Precision Measurement The X-Ray Orientation Analyzer operates based on Bragg's diffraction law. When X-rays strike the crystal surface, the regularly arranged atomic planes within the crystal generate diffraction phenomena at specific angles. By capturing these diffraction signals with precision detectors and calculating the diffraction angles, the instrument can accurately determine the crystal's orientation, providing reliable data for subsequent cutting and processing. Compared to traditional orientation methods, X-ray crystal orientation technology offers significant advantages of being non-destructive, high-precision, and highly efficient, ensuring reliable measurement results without damaging the sample. The instrument achieves a measurement accuracy of ±30 arcseconds (±30″), with a minimum reading of 10 arcseconds, meeting the orientation requirements of the vast majority of crystal materials. Product Series: Comprehensive Solutions for Diverse Application Needs Dandong Tongda Technology's X-Ray Orientation Analyzers primarily include two foundational models: the TYX-200 and the TYX-2H8. The TYX-200 model, as the base version, features a digital display with a minimum reading of 10″ and a measurement accuracy of ±30″, making it suitable for routine crystal material orientation needs. The TYX-2H8 model is a comprehensive upgrade of the TYX-200, featuring an improved goniometer structure, enhanced load-bearing tracks, and a raised sample stage. The TYX-2H8 can measure samples weighing 1-30 kg with diameters of 2-8 inches. Certain configurations can even be extended to handle samples weighing 30-180 kg, with diameters up to 350 mm and lengths up to 480 mm. For more complex research requirements, the company also offers the TDF series X-Ray Orientation Analyzers, which utilize imported PLC control technology, offer a tube voltage range of 10-60 kV, and enable broader functionalities including single-crystal orientation, defect detection, and lattice parameter determination. Functional Applications: A Key Tool for Crystal Processing Across Multiple Industries The X-Ray Orientation Analyzer can precisely and rapidly determine the cutting angles of natural and synthetic single crystals and, in coordination with cutting machines, perform oriented cutting. It is an indispensable instrument for the precision machining and manufacturing of crystal devices. In the semiconductor industry, the instrument is widely used for inspecting ingots, wafers, and chips, controlling processes such as cutting, grinding, and polishing to ensure consistent performance of semiconductor devices. For optical crystal and laser crystal processing, the instrument can accurately determine crystal orientation, ensuring the optical performance of optical devices meets design requirements and improving product yield. Particularly in the field of sapphire crystal processing, the instrument can simultaneously satisfy the measurement requirements for sapphire A, C, M, and R crystal orientations, with an electrically adjustable measurement range of 0–45°, adapting to complex processing needs. In the jewelry and gemstone industry, the instrument supports precise orientation of gemstones, enhancing cutting accuracy and the value of finished products, helping manufacturers maximize the optical effects and commercial value of gemstones. Product Features: Innovative Design Enhances User Experience Dandong Tongda Technology's X-Ray Orientation Analyzers incorporate several innovative features that significantly improve the instrument's practicality and reliability. Easy Operation: The instrument can be operated without professional knowledge or extensive skill, lowering the barrier to use and reducing personnel training time. Digital Display: The digital angle display provides intuitive observation, reduces reading errors, and can be zeroed at any position, facilitating direct display of the wafer's angle deviation. Efficient Design: Some models are equipped with dual goniometers that can operate simultaneously, greatly improving inspection efficiency. Enhanced Precision: A special integrator with peak amplification improves detection accuracy, and a vacuum suction sample plate ensures stable sample positioning. Reliability and Durability: The integrated design of the X-ray tube and high-voltage cable enhances high-voltage reliability. The detector high voltage utilizes a DC high-voltage module, ensuring long-term stable operation. Safety Protection: The instrument uses high-density, high-transmittance lead glass as the X-ray protective shield. The external radiation dose does not exceed 0.1 µSv/h, complying with international safety standards. Sample Stage Configuration: Flexible Adaptation to Diverse Measurement Needs To meet the measurement requirements for samples of different shapes and sizes, Dandong Tongda Technology offers various sample stage configurations: TA Type Sample Stage: Designed specifically for cylindrical crystal rods, equipped with load-bearing tracks. It can measure crystal rods weighing 1-30 kg with diameters of 2-6 inches (expandable to 8 inches), and can measure the reference surface of rod-shaped crystals or the surface of sheet-shaped crystal wafers. TB Type Sample Stage: Also designed for cylindrical crystal rods, it incorporates V-shaped support rails and can measure crystal rods up to 500 mm in length, making it particularly suitable for measuring the end faces of rod-shaped crystals. TC Type Sample Stage: Primarily used for detecting the outer circumference reference surface of single crystal wafers such as silicon and sapphire. Its open design overcomes issues of X-ray obstruction and positioning inaccuracies caused by suction plates. TD Type Sample Stage: Designed specifically for multi-point measurement of wafers like silicon and sapphire. The wafer can be manually rotated on the stage (e.g., 0°, 90°, 180°, 270°) to meet specific customer measurement requirements. Global Market: Empowering International Clients to Achieve Technological Breakthroughs Products from Dandong Tongda Technology Co., Ltd. have successfully entered the international market, exporting to multiple countries and regions including the United States, South Korea, Iran, Azerbaijan, Iraq, and Jordan. Adhering to the principles of "Customer First, Product First, Service First," the company provides global users with high-quality high-tech products and comprehensive technical support. For overseas customers, the company offers full technical consultation and after-sales service, including operational training, maintenance support, and spare parts supply, ensuring users have no concerns. Addressing the needs of clients in different regions, the company can also provide customized solutions, including special sample stage design and measurement software adjustments, ensuring the instrument perfectly adapts to specific application scenarios. Multi-language operation interfaces and detailed English technical documentation further lower the usage barrier for overseas customers and enhance the international user experience. Dandong Tongda Technology's X-Ray Orientation Analyzer is not merely a measurement tool but a strategic partner for enhancing corporate competitiveness. It can significantly shorten the R&D cycle for crystal materials, optimize production processes, ensure product quality, and create tangible value for the global crystal manufacturing industry. Whether in semiconductor chip manufacturing, optical component processing, or new material research, choosing Dandong Tongda Technology means opting for reliable, efficient, and precise crystal orientation solution.

Dandong Tongda, a leading Chinese manufacturer, produces advanced X-ray crystal orienters. Utilizing X-ray diffraction, these instruments enable precise cutting angle measurement and directional cutting of various crystals. Key models like TYX-200 and TYX-2H8 offer high accuracy (±30″), large sample capacity, user-friendly operation, and efficient detection. Widely used in semiconductor, optics, and research fields, these world-class instruments are certified, patented, and exported globally.

The automatic X-ray orientation instrument is a device that uses the diffraction principle of X-ray to determine the crystal structure, orientation, and lattice parameters. It has a wide range of applications in materials science, geology, physics, and chemistry, especially in studying the microstructure and properties of single crystal, polycrystalline materials, and thin film materials. The following will provide a detailed introduction to the working principle, application, and operational precautions of the X-ray crystal orienter. With the advancement of technology, the automatic X-ray orientation instrument devices continues to improve, with higher resolution and easier operation. At the same time, the combination with other analytical techniques such as electron microscopy and spectroscopic analysis makes the analysis of crystal structure more comprehensive and in-depth. In addition, portable and online monitoring X-ray orientation analyzer devices have gradually developed, providing possibilities for on-site analysis and real-time monitoring. In summary, X-ray orientation analyzer is a powerful analytical tool that is crucial for understanding and controlling the microstructure of materials. With the continuous development of technology, its application in various fields will become more extensive and in-depth.

The X-ray orientation analyzer is a device that uses the principle of X-ray diffraction to determine crystal orientation. It is widely used in fields such as materials science, geology, physics, etc., for studying crystal structure, lattice parameters, crystal defects, etc. The working principle of an X-ray orientation analyzer is to irradiate a monochromatic X-ray beam onto the crystal under test. When the X-ray interacts with atoms in the crystal, scattering occurs. According to Bragg's law, when the wavelength of X-rays is an integer multiple of the atomic spacing in a crystal, scattered light will interfere and form a series of alternating bright and dark stripes, known as Bragg reflection. By measuring the angles and intensities of these Bragg reflections, information such as crystal orientation and lattice parameters can be calculated. The X-ray orientation analyzer usually includes the following main parts: 1.X-ray source: a device that produces monochromatic X-rays, typically using an X-ray tube or synchrotron radiation source. 2.Sample stage: a platform used to place the crystal to be tested, which can adjust the position and angle of the crystal. 3.Detector: used to receive scattered X-rays and convert them into electrical signals. Common detectors include scintillation counters, proportional counters, etc. 4.Data acquisition and processing system: used to collect signals output by detectors, and perform data processing and analysis. Usually includes multi-channel analyzers, computers, and other equipment. 5.Control system: used to control the movement of X-ray source, sample stage, and detector to achieve measurement of crystals in different directions. By using an X-ray orientation analyzer, researchers can accurately determine the orientation and lattice parameters of crystals, thereby gaining a deeper understanding of their structure and properties. This is of great significance for the development of new materials, geological exploration, crystal growth and other fields.

Automatic X-ray orientation instrument is an indispensable instrument for precision processing and manufacturing crystal devices. It is widely used in the research, processing and manufacturing of crystal materials.

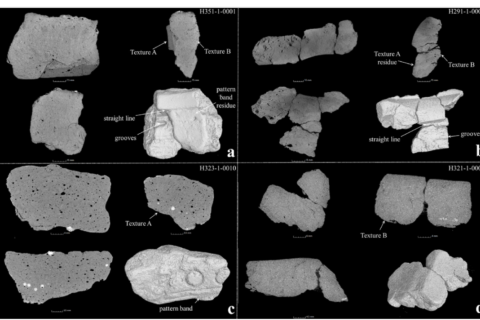

Micro-ct technology has significant advantages in the characterization of ceramics, which can reveal the composite structure inside the material without damage, and restore the key technology in the production of ceramics.

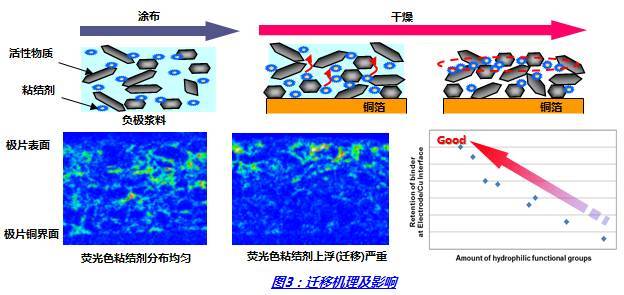

Binder is a polymer compound used in electrode making to adhere the active substance to the collector fluid. The main function is to bond and maintain active substances.