- Home

- >

News

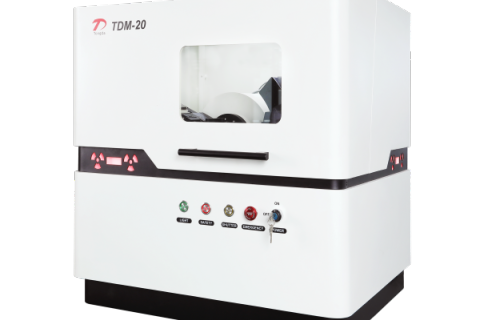

The TDM-20 X-ray Diffractometer (Benchtop XRD) is primarily used for phase analysis of powders, solids, and paste-like substances. Based on the principle of X-ray diffraction, it enables qualitative and quantitative analysis, as well as crystal structure analysis, of polycrystalline materials like powdered samples and metal samples. It is widely applied in industries including industry, agriculture, national defense, pharmaceuticals, mineralogy, food safety, petroleum, and education/research. Core Principle: X-ray Diffraction, the Key to the Microscopic World The TDM-20 X-ray Diffractometer operates on the principle of X-ray diffraction. When X-rays illuminate a sample, they interact with the atoms in the sample and diffract. Different crystal structures produce unique diffraction patterns, much like individual fingerprints. By analyzing these patterns, the instrument precisely reveals key information about the sample's crystal structure, phase composition, and more, uncovering the secrets hidden at the microscopic level. Performance Breakthrough The TDM-20 X-ray Diffractometer (Benchtop XRD) surpasses the previous international standard of 600W, undergoing a comprehensive upgrade to 1200W. The instrument features simple operation, stable performance, and low energy consumption. It can be equipped with either a proportional detector or a new high-speed array detector, resulting in a significant leap in overall performance. Device Features Compact size and lightweight design High-frequency, high-voltage power supply design for lower overall energy consumption Supports rapid sample calibration and testing Simplified circuit control for easy debugging and installation Full-spectrum diffraction angle linear accuracy reaches ±0.01° Rich Accessories The TDM-20 can be paired with various accessories, including a 1D array detector, proportional detector, 6-position automatic sample changer, rotating sample stage, among others. Conclusion The TDM-20 X-ray Diffractometer (Benchtop XRD) , with its outstanding performance, user-friendly operation, and broad range of applications, has become an indispensable tool across numerous industries and research fields. It acts like a "detective" of the microscopic world, helping us unravel the mysteries of material structure and driving progress in various domains. If you too seek to delve deeper into the microscopic secrets of matter, consider the TDM-20 to embark on a journey of precise and efficient research and production.

The TDM-20 desktop X-ray diffractometer is a compact desktop device mainly used for material phase analysis and crystal structure research. 1. The core functions of TDM-20 desktop X-ray diffractometer Phase analysis of TDM-20: TDM-20 can perform qualitative/quantitative analysis on polycrystalline samples such as powders, solids, and paste materials. Crystal structure analysis of TDM-20: Based on the principle of X-ray diffraction, TDM-20 supports the analysis of crystal structures of metal samples, minerals, compounds, etc. 2. Technical characteristics of TDM-20 desktop X-ray diffractometer The high power and performance of TDM-20: using high-frequency high-voltage power supply, the power is increased to 1600W. Equipped with new high-speed array detectors or proportional detectors to improve data acquisition efficiency and accuracy. Convenient operation of TDM-20: The device is small in size and light in weight, suitable for compact laboratory spaces; Supports fast calibration and testing, with simple circuit control and easy installation and debugging. The accuracy and stability of TDM-20: the angle repeatability is as high as 0.0001 °, and the full spectrum diffraction angle linearity is ± 0.01 °. Scalability of TDM-20: TDM-20 can be equipped with a 6-digit automatic sample changer, a rotating sample stage, a low-temperature cooling system, and in-situ high/medium low temperature accessories to meet diverse testing needs. 3. Application scenarios of TDM-20 desktop X-ray diffractometer The research fields of TDM-20 include crystal structure characterization and phase transition analysis in materials science, geology, and pharmaceutical research. Industrial applications of TDM-20: pharmaceutical industry drug consistency assessment, mineral identification, petrochemical catalyst analysis, food safety testing (such as crystal composition determination). Education and National Defense of TDM-20: Rapid Phase Identification in University Teaching Experiments and National Defense Material Development. 4. Manufacturers and accessories of TDM-20 Manufacturer: Dandong Tongda Technology Co., Ltd. Optional accessories: one-dimensional array detector, proportional detector, 6-digit automatic sample changer, rotating sample stage, graphite bent crystal monochromator, etc. Overall, TDM-20, with its high power, high precision, and compact design, has become an efficient tool for laboratory phase analysis and is widely used in scientific research, industry, and teaching fields.

TDM-20 Mini X-Ray Diffractometer is a high-performance benchtop analytical instrument developed and manufactured by Dandong Tongda Technology Co., Ltd. It is primarily used for phase analysis of polycrystalline materials such as powders, solids, bulk specimens, and pastes. Utilizing the principle of X-ray diffraction, the instrument enables qualitative and quantitative analysis, crystal structure analysis, and other functions. It finds extensive applications across various fields including industry, agriculture, defense, pharmaceuticals, mineralogy, food safety, petroleum, and educational research. TDM-20 Benchtop X-ray Diffractometer breaks through the conventional 600W limitation, delivering a maximum output power of 1200W for high-power performance. Additionally, it incorporates a high-frequency, high-voltage power supply, resulting in lower overall power consumption. It boasts high-precision goniometer technology with an angular repeatability of 0.0001°, a diffraction peak position measurement accuracy of 0.001°, and a full-profile diffraction angle linearity of ±0.010°.The instrument incorporates an advanced control system based on PLC (Programmable Logic Controller) technology and a modular design for precise operation. For detection, it can be equipped with either a proportional detector or a new high-performance array detector, significantly enhancing overall performance and data acquisition speed. The TDM-20 also offers highly flexible configuration options, supporting a variety of accessories such as a rotating sample stage, a 1D array detector, and a 6-position automatic sample changer. TDM-20 Mini X-Ray Diffractometer is further characterized by its significant advantage of being compact and portable, with a small footprint and low weight. It is recognized as one of the smallest benchtop X-ray diffractometers globally, rendering it highly suitable for laboratory environments where space is limited. Furthermore, the instrument is provided with a triple interference-free isolation protection scheme. The X-ray leakage radiation is maintained at ≤ 0.12 μSv/h, ensuring compliance with the GBZ 115-2002 protection standard. Hence, the use of the TDM-20 Mini X-Ray Diffractometer is confirmed to be safe and reliable. TDM-20 Mini X-Ray Diffractometer integrates high power, high precision, and a compact design into a single platform. It transcends the limitations of traditional, large-scale X-ray diffractometers, delivering an efficient, convenient, and reliable material analysis solution for various industries. With its advanced technical performance, comprehensive service support, and flexible operation, the TDM-20serves as a powerful tool for laboratory-based material analysis. If you have any requirements for X-ray diffraction equipment, we welcome you to choose the products from Dandong Tongda Science and Technology Co., Ltd.

The TDM-20 desktop X-ray diffractometer is mainly used for phase analysis of powders, solids, and similar paste like materials.Benchtop XRD utilizes the principle of X-ray diffractometer to perform qualitative or quantitative analysis, crystal structure analysis, and other polycrystalline materials such as powder samples and metal samples. The TDM-20 desktop X-ray diffractometer is widely used in industries such as industry, agriculture, national defense, pharmaceuticals, minerals, food safety, petroleum, education, and scientific research. The loading of a new high-performance array detector has led to a significant improvement in the performance of benchtop XRD。 Benchtop XRD equipment has a small volume and light weight; The working power of the Benchtop XRD high-voltage power supply can reach 1600 watts; Benchtop XRD can quickly calibrate and test samples; Benchtop XRD circuit control is simple and easy to debug and install; The repeatability of the Benchtop XRD angle can reach 0.0001.

Due to the different crystallization conditions, the particles of powder drug samples will have different morphologies.

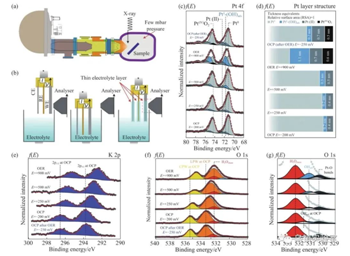

X-ray diffraction (XRD) is a means of research to obtain information such as the composition of a material, the structure or form of an internal atom or molecule by analyzing its diffraction pattern through X-ray diffraction.

In August 2023, under the leadership of the company, the big family of Dandong Tongda Technology Co., Ltd. in Liaoning Province held an outdoor dinner on the eve of the end of the month.