- Home

- >

News

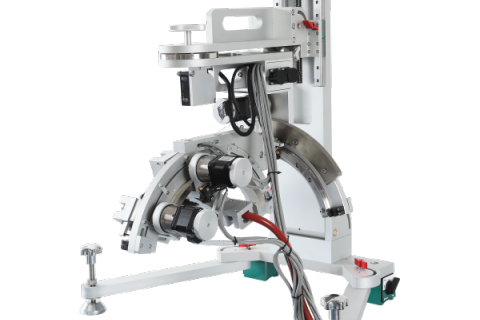

In the field of materials science research, precise measurement serves as the key to unlocking material properties. The multi-functional integrated measurement accessory developed by Dandong Tongda Science and Technology Co., Ltd. is a high-precision tool designed to enhance X-ray diffraction analysis capabilities. This multi-functional integrated measurement accessory is specifically designed for installation on wide-angle goniometers. Its core mission is to accurately analyze plate materials, bulk materials, and thin films deposited on substrates. The accessory can perform various measurement tasks, including crystal phase detection, orientation degree analysis, and stress testing. It supports texture analysis, residual stress determination, and in-plane structure testing of thin films, providing comprehensive data support for materials research. The core technical features of this accessory are reflected in its multi-axis coordinated precision mechanical system and highly adaptable measurement methods. The multi-functional integrated measurement accessory supports pole figure measurements using either transmission or reflection methods, offering flexibility for different samples and testing requirements. For stress testing, it can employ both the side-inclination method and the normal-inclination method. For thin film samples, the accessory also enables in-plane rotation testing, allowing for in-depth analysis of film structures. Its precision mechanical system ensures high measurement accuracy and repeatability, with minimum step increments of 0.001° (for rotation axes) and 0.001mm (for translation axes). The application scope of the multi-functional integrated measurement accessory is extremely broad, covering almost all advanced manufacturing and R&D fields that require material structure analysis. In the field of metal materials, it is used for evaluating the collective organization of metals such as rolled plates; in ceramics, it focuses on assessing ceramic orientation. For thin film materials, the accessory can analyze the preferred crystal orientation of film samples and test the residual stress of multilayer films (evaluating properties such as film peeling). It can also analyze surface oxidation and nitridation films on high-temperature superconducting material films and metal plates, as well as multilayer films on glass, silicon, and metal substrates. Notably, it can also be applied to the analysis of macromolecular materials, paper, lens plating materials, and more, demonstrating its interdisciplinary application potential. Measurement Accessory

The multi-functional residual stress analyzer developed by Dandong Tongda Technology Co., Ltd. is designed to meet the needs of fast and accurate measurements in both laboratory and field environments. Based primarily on the X-ray diffraction principle, it enables non-destructive testing of the residual stress state inside materials. Versatile All-in-One Analysis This analyzer integrates multiple material analysis functions, significantly enhancing equipment utility and efficiency: Residual Stress Analysis: Supports various measurement modes such as standard同倾法 (omega-inclination), standard侧倾法 (psi-inclination), and standard摇摆法 (oscillation), capable of determining principal stresses and shear stresses for a comprehensive stress state evaluation. Retained Austenite Analysis: Employs the four-peak method for retained austenite testing, with fully automated data calculation for quick results. Diffraction Phase Analysis: Used to analyze crystal structures, chemical composition content, and distribution, helping researchers gain deeper insights into material constitution. Grain Size Analysis: Supports grain size evaluation from nanoscale to sub-micron scale, particularly suitable for fine grains ≤200 nm. Technical Features and Performance This instrument boasts multiple technical features aimed at ensuring precision, stability, and ease of use: High-Precision Measurement and Control: Utilizes a high-precision fully closed-loop vector drive servo system to ensure measurement accuracy and repeatability. Efficient Data Acquisition: Equipped with a multi-channel silicon strip linear array detector, which provides noise-free performance, high-intensity measurement, and rapid data collection to enhance detection efficiency. Portable Design: Features a lightweight construction, making it suitable not only for laboratory environments but also for on-site rapid measurements, adapting to various testing scenarios. User-Friendly Operation: Integrates Windows OS or automation functions, supporting one-click testing and real-time result display, lowering the operational barrier. Modularity and Safety: Employs a PLC control system with modular design for ease of operation and stable performance. Safety-wise, its low-power X-ray design complies with relevant safety standards, with radiation levels significantly below the annual public dose limit. Broad Application Fields Dandong Tongda’s multi-functional residual stress analyzer has extensive applications, covering almost all industrial sectors and research institutions requiring evaluation of material mechanical properties: Manufacturing Quality Control: Used to detect residual stresses in stamped, cast, and rolled parts during processing. Automotive Industry: Tests residual stresses in critical components such as camshafts and connecting rods to ensure reliability and durability. Aerospace: Evaluates working loads in critical areas of aerospace materials to assess safety. Materials Science Research: Applicable to various metal materials (e.g., carbon steel, alloy steel, titanium alloy, nickel-based materials), glass, and composite materials for residual stress, retained austenite, phase, and grain size analysis. Dandong Tongda Technology Co., Ltd.’s multi-functional residual stress analyzer demonstrates the company’s technical expertise in the field of material testing by integrating multiple analytical functions. This instrument provides engineers and researchers with a window into the intrinsic stress state of materials, helping to control product quality at the source, optimize process parameters, and thereby enhance product reliability and durability.

Multifunctional Integrated Measurement Attachment enables precise texture, stress and thin-film analysis. Supports pole figure mapping, biaxial stress measurement and in-plane rotation. Ideal for metals, ceramics, coatings and polymers. Features 0.001° step precision and Φ100mm sample capacity.

The TDTC-150 Multi-functional Residual Stress Analyzer integrates core analytical functions including high-precision residual stress analysis, quantitative retained austenite measurement, and phase/crystallite size analysis into a single device. It features a modular PLC control system, a lightweight portable design, and a high-precision servo system with a multi-channel detector for efficient, high-resolution data acquisition. The instrument supports a wide range of materials such as steels, titanium alloys, and composites. Dandong Tongda Technology, with its established global export experience, offers the TDTC-150 to meet the growing international demand for reliable, multi-functional material testing solutions in advanced manufacturing and R&D.