- Home

- >

News

Amidst ongoing breakthroughs and technological innovations in global materials science, China's scientific instrument manufacturing industry is steadily rising to prominence. The TDF Series X-ray Crystal Analyzer, developed by Dandong Tongda Technology Co., Ltd., represents a leading example of domestically produced high-end analytical instrumentation. It is gaining traction in global scientific research and industrial sectors precisely due to its exceptional performance and reliable precision. The TDF Series X-ray Crystal Analyzer is a major analytical instrument designed for investigating the internal microstructure of substances. Its key applications encompass crystal orientation, defect inspection, lattice parameter determination, and residual stress measurement. Whether analyzing the structure of plates and rods, or deciphering the structure of unknown materials and single crystal dislocations, this equipment delivers accurate and reliable data support. In modern fields like materials science, semiconductor manufacturing, new energy development, and pharmaceuticals, a deep understanding of material microstructure has become the cornerstone of technological progress. The TDF Series is engineered for this purpose – empowering scientists and engineers worldwide to unlock the secrets of material properties. Vertical Tube Housing & Four-Port Design The TDF Series X-ray Crystal Analyzer incorporates a unique vertical tube housing design with four usable ports simultaneously. This innovative design significantly enhances operational efficiency, allowing users to switch rapidly between multiple experimental channels and save valuable research time. Precision Control with PLC Technology Equipped with an imported PLC control system, the TDF Series X-ray Crystal Analyzer demonstrates outstanding performance in control precision and anti-interference capabilities. This system not only enables precise control of high-voltage switching and lifting operations but also features an automatic X-ray tube training function, effectively extending the service life of both the X-ray tube and the entire instrument. For experimental scenarios requiring long-term, continuous operation, this reliability substantially reduces the risk of equipment failure and potential data loss. Powerful and Stable High-Voltage Generation System The high-voltage generator of the TDF Series performs exceptionally well, offering a tube voltage adjustable from 10 to 60 kV and a tube current range from 2 to 80 mA, with a rated output power of up to 5 kW. The stability of tube voltage and current reaches 0.3‰, ensuring highly reproducible experimental data. The system is also equipped with multiple protection functions (e.g., no voltage, overvoltage, no mA, over-power, no water, X-ray tube overtemperature), providing comprehensive safety assurance. Versatile X-Ray Tube Configurations To accommodate diverse analytical needs, the TDF Series offers a choice of various target materials, including Cu, Co, Fe, Cr, Mo, and W. With a rated power of 2.4 kW and focal spot options of point focus (1×1) and line focus (1×10), users can select the most suitable configuration based on sample characteristics and analytical objectives. Comprehensive Safety Protection Design Safety performance is another standout feature of the TDF Series X-ray Crystal Analyzer. Utilizing high-density, high-transparency lead glass for the X-ray protective shielding, the external radiation leakage is maintained at ≤ 0.1 μSv/h – a level well below international safety standards – ensuring reliable protection for operators. Configurations for Diverse Application Scenarios The TDF Series X-ray Crystal Analyzer supports various X-ray cameras, including Laue cameras (large/small powder), flat panel cameras, 3D sample stages, and Multiwire cameras (US-made). This flexible configuration scheme enables the instrument to adapt to a wide range of requirements, from fundamental research to high-end materials analysis. For applications demanding high-precision positioning, the TDF Series X-ray Crystal Analyzer offers a maximum positioning speed of up to 1500°/min, ensuring fast and accurate data acquisition. Whether for analyzing unknown materials in scientific research or for quality monitoring in industrial production, the TDF Series provides a dependable solution. As cutting-edge fields like new materials, new energy, and semiconductors continue to develop rapidly, the demand for material microstructure analysis is growing, and the required precision is constantly increasing. The TDF Series X-ray Crystal Analyzer will continue to evolve and upgrade to meet the latest needs of the global scientific and industrial communities. Dandong Tongda Technology Co., Ltd. remains committed to its philosophy of technological innovation and quality first. We will continue to provide global users with superior products and services, working hand-in-hand with scientists and engineers worldwide to jointly advance materials science and enhance industrial quality standards. We invite global partners and users to inquire and discuss collaboration opportunities. Discover more about the technical details and application cases of the TDF Series X-ray Crystal Analyzer. Let's join hands to explore the mysteries of the microscopic world of materials and jointly drive technological innovation and industrial progress!

Dandong Tongda's X-ray Crystal Analyzer adopts advanced X-ray diffraction technology, enabling non-destructive detection of microstructural information in various materials. Whether it's single crystal orientation, defect inspection, lattice parameter measurement, or residual stress analysis, this instrument provides accurate and reliable test data, offering solid support for material research and quality control. The instrument is equipped with a highly stable X-ray generator that delivers exceptional performance. The tube voltage can be precisely adjusted within the range of 10-60kV, and the tube current can be regulated from 2-60mA, with a stability of no more than ±0.005%. This ensures highly repeatable and accurate test results, providing researchers with dependable data assurance. Dandong Tongda's X-ray Crystal Analyzer integrates intelligent control and comprehensive safety protection. It features an imported PLC automatic control system, enabling unattended automatic timed measurements. The multi-level safety protection system includes no-pressure, no-current, over-voltage, over-current, over-power, no-water, and X-ray tube over-temperature protections, ensuring the safety of operators. The TDF series X-ray crystal analyzer adopts a vertical tube housing with four windows that can be used simultaneously. It utilizes imported PLC control technology, which offers high precision and strong anti-interference capabilities, ensuring the reliable operation of the system. The PLC controls the switching and adjustment of high voltage and includes an automatic training function for the X-ray tube, effectively extending the service life of both the X-ray tube and the instrument. The instrument's radiation protection enclosure is constructed with high-density, high-transparency leaded glass, with external radiation leakage far below national safety standards, allowing researchers to conduct experimental studies in a secure environment. As a national high-tech enterprise, Dandong Tongda Technology Co., Ltd. has a comprehensive quality management system and a technical R&D team. Its products not only meet domestic market demands but are also exported to numerous countries and regions, demonstrating the strength and capability of China's scientific instrument manufacturing. Dandong Tongda's X-ray Crystal Analyzer, with its outstanding performance and reliable quality, has become a powerful assistant in the field of material analysis. It helps researchers and engineers unveil the layers of the material world and explore more unknown possibilities.

The TDF series X-ray crystal analyzer delivers exceptional performance in microstructure analysis, supporting single crystal orientation, defect detection, and stress measurement. Featuring a vertical tube design with multi-window operation and imported PLC control, it ensures high precision, safety compliance (radiation <0.1 µSv/h), and adaptability across industries. Backed by ISO certification and global exports, this instrument empowers scientific and industrial advancements worldwide

Product Spotlight: Dandong Tongda's X-Ray Crystal Analysis Solutions Dandong Tongda Science and Technology introduces its advanced X-ray crystal analysis equipment, delivering precision and reliability for industrial applications. The TDF Series X-Ray Crystal Analyzer combines powerful analytical capabilities with industrial-grade reliability. Featuring four operational windows and PLC control technology, it serves high-end manufacturing sectors including semiconductor wafer inspection, aerospace component stress evaluation, and laser crystal processing. Our X-Ray Crystal Orientators (TYX-200/TYX-2H8) enable rapid, precise measurement of crystal cutting angles with accuracy up to ±30 arcseconds. Capable of handling samples up to 30kg, these instruments support directional cutting of piezoelectric, optical, laser, and semiconductor crystals. Both product lines utilize non-destructive X-ray diffraction technology, replacing traditional radioactive methods while improving processing efficiency and accuracy for crystal material research and manufacturing.

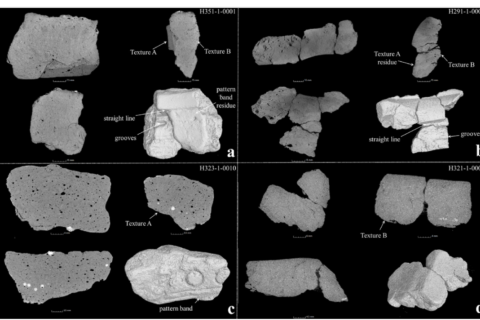

Micro-ct technology has significant advantages in the characterization of ceramics, which can reveal the composite structure inside the material without damage, and restore the key technology in the production of ceramics.