- Home

- >

News

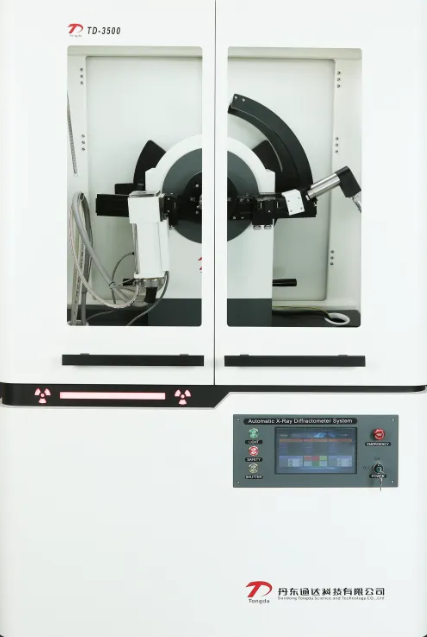

Dandong Tongda Technology Co., Ltd., a leading Chinese manufacturer of analytical instruments, is proud to present its flagship product to the global market: the TD-3500 X-ray Diffractometer (XRD). Meticulously engineered with cutting-edge technology and precision craftsmanship, the TD-3500 is designed to deliver an exceptional analytical experience for global research institutions, university laboratories, and industrial quality control departments. The TD-3500 is far from an ordinary X-ray diffractometer. It embodies Tongda Technology's profound technical expertise and deep understanding of user needs. Designed around the core principles of "Precise, Efficient, Stable, and User-friendly," it is committed to becoming your most reliable laboratory partner. This high-precision instrument is widely used in material analysis and excels at in-depth microstructural analysis of powders, bulk solids, and thin films. Core Technical Specifications & Features High-Stability X-Ray Generator: Utilizes an imported PLC (Programmable Logic Controller) for precise control. With a rated power of up to 5kW, wide tube voltage and current ranges (10-60kV, 2-80mA), and an output stability better than 0.01%, it guarantees exceptionally stable and reliable data acquisition. High-Precision Goniometer: The heart of the diffractometer features imported high-precision bearings and a fully closed-loop vector drive servo system. It offers extremely high angular reproducibility (minimum step size of 0.0001 degrees), ensuring unparalleled measurement accuracy. Its vertical (θ-θ) design keeps the sample stationary and horizontal during testing, making it suitable not only for solids but also for challenging states like liquids, gels, and viscous samples. Low-Noise Detection & Counting System: Equipped with high-performance proportional or scintillation counters, the system boasts a wide counting linear range (≥700,000 cps) with very low background noise (≤1 cps), effectively capturing weak diffraction signals for enhanced data accuracy. Comprehensive Safety Protection: Safety is paramount. The TD-3500 is equipped with a dual protection system: the shutter interlock is linked to the lead door. If the door is accidentally opened, the shutter closes automatically, high voltage drops to a safe level, and data acquisition halts immediately, maximizing operator safety. Radiation leakage is significantly below national standards. Powerful Analysis Software & Database: The system includes robust software for data collection and processing, integrated with professional analysis tools like Jade and the PDF database. Notably, it features a dedicated measurement program for the titanium dioxide industry, enabling rapid and accurate analysis of Rutile and Anatase content with errors controlled within 0.2%. Key Competitive Advantages of the TD-3500 1. Exceptional Performance & Precision High Resolution & Intensity: An optimized optical path and highly stable X-ray generator ensure high-resolution, high signal-to-noise ratio diffraction patterns. It delivers impeccable data quality for both qualitative/quantitative phase analysis and precise lattice parameter calculations. Robust Stability: Core components feature a fully enclosed protective design, coupled with a precise temperature control system. This ensures ultra-high stability and data reproducibility during long-term continuous operation, meeting the most stringent demands of industrial online detection. 2. Intelligent & User-Friendly Operation One-Click Smart Operation: The new-generation intelligent control software features an intuitive interface and smooth operation. Even novice users can easily complete complex testing tasks using pre-set programs, significantly reducing the learning curve and operational barriers. Powerful Data Analysis Capabilities: The software incorporates a powerful database and advanced analysis algorithms, enabling rapid phase identification, crystallite size and microstrain calculation, residual stress analysis, and more, helping you extract key insights from vast amounts of data quickly. 3. Wide Applicability & Flexibility The TD-3500 effortlessly handles samples of various forms—powder, bulk, thin film—finding applications across diverse fields such as new material R&D, metallurgy, chemicals, pharmaceuticals, cement, ceramics, geological exploration, and cultural heritage authentication. Its modular design also allows for future functional expansions, protecting your investment. 4. Rugged Construction & Global Support Built with meticulous attention to detail and superior materials, the TD-3500 ensures stable operation in various complex environments worldwide. Furthermore, Dandong Tongda Technology Co., Ltd. has established a comprehensive global sales and service network, providing professional pre-sales consultation, technical training, and timely after-sales support to ensure peace of mind for customers anywhere in the world. Our Commitment With years of deep expertise in the X-ray analysis instrument field, we understand the unique challenges each customer faces. The launch of the TD-3500 X-ray Diffractometer represents not only the pinnacle of our technology but also our commitment to empowering global customer success. "We are dedicated to bringing the world's scientists and engineers the most reliable technological tools through continuous innovation," said the General Manager of Tongda Technology. "The TD-3500 X-ray Diffractometer is our sincere offering to the market. We believe it will become a powerful engine for our customers to explore material mysteries, enhance product quality, and drive technological revolution."

In the fields of materials science and industrial testing, every minute change in crystal structure can determine the final properties of a material. Today, a precision instrument embodying the essence of R&D from Dandong Tongda Science and Technology— TD-3500 X-ray Diffractometer—is opening a new window into the microscopic world for researchers and industrial inspectors with its outstanding performance and intelligent design. Evolution Through Craftsmanship and Technology The TD series diffractometers incorporate years of technological accumulation from Tongda Science and Technology, continuously evolving with the times. As the "gold standard" for material analysis, X-ray diffraction technology enables comprehensive structural analysis of powder, bulk, or thin-film samples: from qualitative and quantitative phase analysis, crystal structure analysis, and material structure analysis, to orientation analysis, macro/micro stress measurement, grain size, and crystallinity determination—the TD-3500 does it all. Intelligent Core, Stable and Reliable The core advantage of the TD-3500 X-ray Diffractometer lies in its use of an imported Siemens PLC control system. This innovative design gives the instrument outstanding features such as high precision, high accuracy, excellent stability, long service life, easy upgradability, user-friendly operation, and intelligent functionality, enabling it to flexibly adapt to the testing and research needs of various industries. The X-ray generator offers two options: high-frequency high-voltage solid-state or工频(line-frequency) generators, with high automation, extremely low failure rates, strong anti-interference capabilities, and excellent system stability. The system automatically controls the shutter switch, adjusts tube voltage and current, and includes an automatic X-ray tube training function. Real-time monitoring via a touchscreen greatly reduces operational complexity. Innovative Control, Revolutionary Operation Compared to traditional single-chip microcomputer circuits, the PLC control technology used in the TD-3500 offers multiple breakthroughs: Simple circuit control for easy debugging and installation Modular design allows users to perform maintenance and debugging themselves, significantly reducing costs Strong expandability for easy addition of various functional accessories without hardware modifications True-color touchscreen for human-machine interaction, user-friendly operation, and intuitive fault information display Precision Measurement, Safety Assured The TD series goniometer uses imported high-precision bearing transmission and is equipped with a high-precision full closed-loop vector drive servo system. The intelligent drive includes a 32-bit RISC microprocessor and a high-resolution magnetic encoder, capable of automatically correcting minute movement position errors to ensure high precision and accuracy of measurement results, with angular reproducibility reaching 0.0001 degrees. For safety, the TD-3500 adopts a hollow-axis structure with electronic lead door interlock装置, providing dual protection. The shutter window is linked to the lead door—when the lead door opens, the shutter automatically closes, ensuring comprehensive operator safety. Flexible Configuration, Comprehensive Compatibility The instrument offers two detector choices—proportional counter (PC) or scintillation counter (SC)—and multiple X-ray tube options including glass, corrugated ceramic, and metal-ceramic tubes, meeting different application scenarios and budget requirements. The TD-3500 X-ray Diffractometer is not only a high-performance analytical instrument but also a reflection of Tongda Science and Technology's relentless pursuit of quality. It is quietly playing a vital role in laboratories across the country, supporting scientific innovation and quality control, and becoming the most trusted analytical partner for scientists and engineers. Whether you are engaged in new material development, mineral resource analysis, pharmaceutical quality control, or metal material testing, the TD-3500 can provide you with accurate and reliable data support, helping you discover more possibilities in the microscopic world. Explore the Unknown with TD-3500—Let Tongda Science and Technology work with you to uncover the mysteries of materials science.

The TD-3500X-ray diffractometer (TD-3500XRD) is a high-performance analytical instrument produced by Dandong Tongda Technology Co., Ltd. It is mainly used for the analysis of crystal structure, phase composition, and material properties. 1. Core technical parameters of TD-3500X-ray diffractometer The X-ray source of TD-3500 diffractometer: Provide Cu K α or Mo K α target material selection, with adjustable tube voltage range of 10~60kV and tube current range of 2~80mA, supporting high-frequency and high-voltage solid-state generators or power frequency generators. Equipped with an imported Siemens PLC control system, it achieves automated light gate switching, tube pressure/flow regulation, and X-ray tube training functions with high stability. Angle measurement system of TD-3500X-ray diffractometer: Adopting a θ -2 θ vertical structure with a diffraction circle radius of 185mm (adjustable to 285mm), it supports testing of liquid, sol, powder, and block samples. The angular resolution reaches 0.0001 degrees, the step accuracy is 0.0001 degrees, and the angle measurement range is -5 °~165 ° (2 θ), suitable for high-precision crystal analysis. Detector of TD-3500X-ray diffractometer: Optional proportional detector (PC) or scintillation detector (SC), with a counting linear range of ≥ 700000 cps and background noise ≤ 1cps. Equipped with dual crystal monochromator technology, effectively suppressing the K α 2 component and improving the monochromaticity of the radiation. Control and software of TD-3500X-ray diffractometer: A human-machine interaction system based on imported PLC and true color touch screen, supporting parameter setting, real-time monitoring, and fault diagnosis. The software has functions such as phase diagram matching, stress analysis, and grain size calculation, and can generate standardized reports. 2. Technical characteristics and advantages of TD-3500X-ray diffractometer High precision and stability of TD-3500X-ray diffractometer: The angle measuring instrument adopts imported high-precision bearings and a fully closed-loop servo drive system, with automatic correction of motion errors and repeatability better than 0.0006 °. PLC modular design has strong anti-interference ability, supports long-term fault free operation, and can expand multiple functional accessories. Safety and protection of TD-3500X-ray diffractometer: The electronic lead door interlocking device achieves dual protection, with the light gate and lead door interlocked to ensure safe operation. Equipped with a circulating water cooling system (split or integrated), it automatically controls the water temperature and monitors the temperature of the X-ray tube to avoid blockage. Intelligent operation of TD-3500X-ray diffractometer: The touch screen displays the instrument status in real-time, supports parameter settings (such as scanning range, step size, sampling time), and remote fault diagnosis. Preset scanning modes (θ -2 θ, single crystal diffraction, thin film analysis) to meet different sample requirements. 3. The main application areas of TD-3500X-ray diffractometer Material analysis of TD-3500X-ray diffractometer: Qualitative/quantitative analysis of phases, identification of crystal structure, determination of grain size and crystallinity. Phase composition and stress analysis of materials such as semiconductors, ceramics, metals, polymers, etc. Research experiment of TD-3500X-ray diffractometer: Analysis of film orientation, phase transition research of catalyst/battery materials, and characterization of nano material structures. Biological crystals, macroscopic/microscopic stress measurement, and material temperature evolution analysis (requiring the use of a thermal analyzer). Typical user case of TD-3500X-ray diffractometer: Wuhan University of Technology (New Material Structure Research), Beijing Institute of Technology (Oxide Semiconductor Phase Transformation Research), Tongji University (Titanium Alloy Structure Analysis), etc. 4. Key points for operation and maintenance of TD-3500X-ray diffractometer Operation process of TD-3500X-ray diffractometer: Start up and preheat for 10-15 minutes → Sample preparation and fixation → Set scanning parameters (such as 2 θ range, step width, tube pressure/flow) → Start scanning → Data analysis. Support the combination of SEM and EDS to achieve comprehensive characterization of micro/nano structures and components. Widely used in materials science, chemistry, physics and other fields, it is the preferred tool for crystal structure and phase analysis.

The TD series diffractometer embodies the essence of Tongda Technology's research and development over the years, evolving with the demands of the times. X-ray diffractometer is mainly used for phase qualitative and quantitative analysis, crystal structure analysis, material structure analysis, crystal orientation analysis, macroscopic or microscopic stress determination, grain size determination, crystallinity determination, etc. of powder, block or film samples. The TD-3500 X-ray diffractometer produced by Dandong Tongda Technology Co., Ltd. adopts imported Siemens PLC control, which makes the TD-3500 X-ray diffractometer have the characteristics of high accuracy, high precision, good stability, long service life, easy upgrade, easy operation and intelligence, and can flexibly adapt to testing analysis and research in various industries! Angle measuring instrument with hollow shaft structure

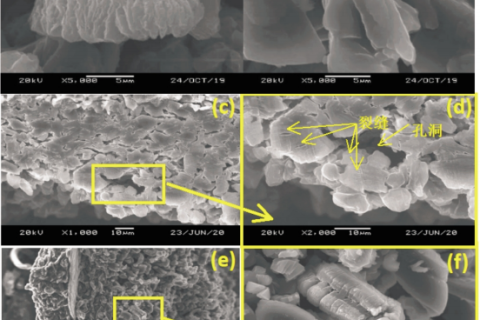

Due to the different crystallization conditions, the particles of powder drug samples will have different morphologies.

This paper mainly analyzes the cause of a black spot phenomenon on the negative surface of lithium iron phosphate battery.

It is a professional manufacturer of X-ray analysis instruments and non-destructive testing instruments, and has obtained a number of certifications such as national high-tech enterprises, ISO quality system certification enterprises, and has an invention patent and utility model patent.

In August 2023, under the leadership of the company, the big family of Dandong Tongda Technology Co., Ltd. in Liaoning Province held an outdoor dinner on the eve of the end of the month.