X-ray Diffraction Residual Stress Analyzer

TD-RSD XRD Residual Stress Analyzer

±7MPa accuracy, dual-detector innovation, full-auto operation & powerful software. Optimize processes, enhance product reliability. Compact, efficient, leading solution.

- Tongda

- Liaoning, China

- 1—2 months

- 100 units per year

- Information

Product Overview

The TD-RSD X-ray Diffraction Residual Stress Analyzer utilizes a 3KW high-power X-ray generator paired with an advanced photon-counting area detector, ensuring reliable measurement data even under complex working conditions. The instrument demonstrates excellent performance in stress-free iron powder tests, with the standard deviation of stress across five consecutive measurements strictly controlled within ±7 MPa.

Technical Parameters:

Overall Dimensions: 1300 × 1200 × 1880 mm

Power Configuration: 3KW

Measurement Accuracy: ±7 MPa

Detector Configuration: Dual photon-counting area detectors

Control System: Fully automated computer control

Standard Configuration

Innovative Diffraction Geometry Design

The instrument features a unique dual-detector system, supporting:

Dual-Detector ψ (Psi) Method: Optimizes conventional stress measurement procedures.

Dual-Detector Ω (Omega) Method: Handles samples with complex geometric shapes.

Oscillation Technique: Significantly improves the accuracy of diffraction intensity measurements.

Precision Motion Control Platform

At the core of the instrument is a meticulously engineered mechanism for adjusting X-ray beam angle and verticality. This ensures an ideal geometric relationship between the X-ray beam and the sample surface at all times. Combined with a fully computer-controlled goniometer system, users can seamlessly switch between the ψ and Ω methods and simultaneously apply the oscillation function, achieving high flexibility in measurement modes.

Intelligent Sample Positioning System

Manual/Auto Focus System: Equipped with a high-precision laser positioning device.

Three-Axis Sample Stage: Capable of drawing stress contour maps and calculating the magnitude and direction of principal stresses.

Visual Operation Interface: Provides real-time monitoring of sample position and measurement status.

Core Component Specifications

High-Performance X-Ray Tube

Employs a fine-focus ceramic X-ray tube with a built-in sealed self-circulating cooling system, ensuring the instrument meets demanding requirements for continuous 24/7 operation. The system integrates an automatic over-temperature protection function for multiple layers of safety. A wide selection of target materials—including Cr, Cu, Mn, Co, V, Ti, Fe, and Mo—is available to meet the analysis needs of different materials.

Advanced Detection System

Configured with two symmetrically arranged high-speed area photon-counting detectors. The total count rate exceeds 1×10⁹ counts per second (cps), completely avoiding the technical saturation common in traditional detectors. This symmetric installation design not only optimizes spatial layout but also ensures measurement efficiency and accuracy, offering compact size, fast response, and extremely high sensitivity.

Powerful Analysis Software

The dedicated analysis software for the TD-RSD analyzer integrates a comprehensive 3D stress analysis module, supporting:

Ellipse fitting and line profile fitting algorithms.

Precise analysis of complex stress states.

Automatic generation of stress contour maps.

Calculation of principal stress magnitude and direction.

Key Customer Value

The TD-RSD X-ray Diffraction Residual Stress Analyzer provides accurate and reliable residual stress data, helping customers:

Optimize manufacturing process parameters.

Improve product reliability and service life.

Reduce the risk of product failure.

Accelerate new product development cycles.

Company Honors & Credentials

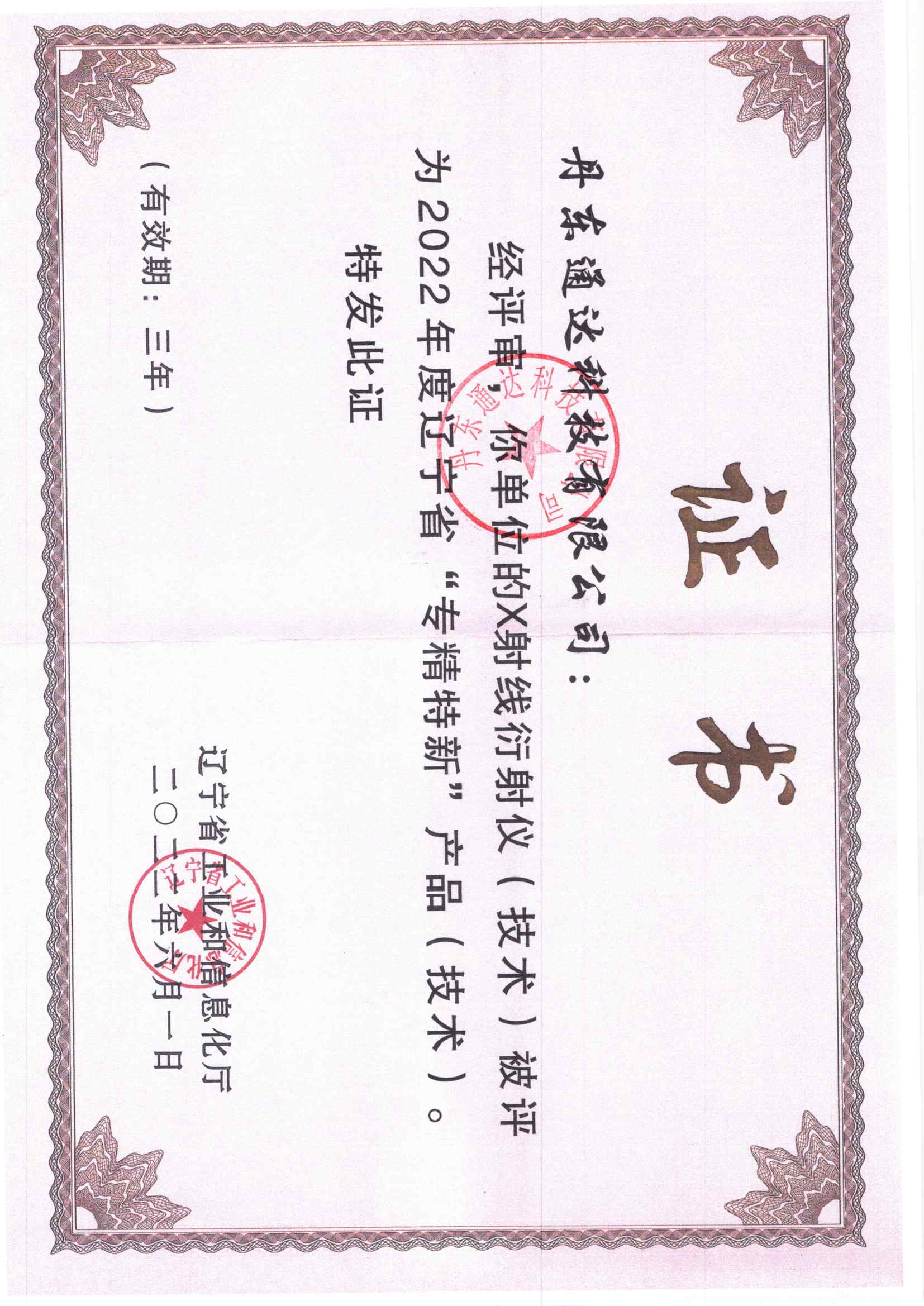

Dandong Tongda Technology Co., Ltd. is committed to developing high-end X-ray analytical instruments. Our technical expertise has been recognized with several official certifications and honors, which underpin the quality of our products like the TD-RSD analyzer:

National High-Tech Enterprise certification.

Recognized as a "Specialized, Refined, Distinctive, and Innovative" (SRDI) SME in Liaoning Province.

Certified as a Technology-based SME.

ISO Quality Management System certification.