- Home

- >

- News

- >

- Company news

- >

News

Originally battery accessories are experimental devices designed specifically for electrochemical testing, mainly used for in-situ characterization of battery materials during charging and discharging processes, commonly found in X-ray diffraction (XRD). 1. Core functions and application scenarios of originally battery accessories (1)Originally testing: Real time monitoring of material phase structure changes (such as crystal structure and phase transition) during battery charging and discharging can avoid sample contamination or state changes caused by battery disassembly. Support multiple electrochemical systems, including composites containing carbon, oxygen, nitrogen, sulfur, metal embedment, etc. (2) Multimodal compatibility: X-ray diffraction (XRD): used to analyze the structural evolution of positive/negative electrode materials during charge and discharge processes. 2. Structural composition and technical characteristics of originally battery accessories (1) Key components: Lower insulation cover: usually made of alumina ceramic or polytetrafluoroethylene material, containing coolant flow channels or resistance wire installation pipelines, used for temperature control. Upper conductive cover: connected to the lower insulating cover by bolts to form a closed space, with a beryllium window (diameter 15mm, thickness 0.1mm) at the top to transmit X-rays. Electrode system: originally battery accessories includes a lower electrode (with a support column) and a butterfly spring, which are electrically connected through compression fixation, simplifying the assembly process. (2) Technological innovation: Formal design: Compared with the traditional inverted method, the formal structure does not require flipping assembly, making it easy to operate in the glove box and ensuring the flatness of the beryllium window and diaphragm. Sealing and temperature control: Integrated coolant circulation pipeline and resistance wire heating device, suitable for a temperature range of -400 ℃ to 400 ℃. 3. Technical advantages of originally battery accessories (1) Simplified operation: Reduce assembly steps, decrease operating time inside glove boxes, and improve efficiency. The butterfly spring fixes the electrode without the need for rotation and tightening, avoiding interference with the simulated structure of the battery. (2) Performance improvement: The high X-ray transmittance (>90%) of beryllium windows ensures the detection signal strength. The multifunctional sample stage supports automatic sample changing and is suitable for high-throughput testing. Overall, originally battery accessoriesare important tools for electrochemical research, as their design optimizes the assembly process of traditional battery simulation structures and enhances the reliability and applicability of originally testing.

A multifunctional sample stage is an experimental or testing platform that integrates multiple functional modules, used to carry, manipulate, and test different types of samples (such as materials, biological samples, electronic components, etc.). It usually has flexible configuration and scalability to meet different experimental needs, and is widely used in scientific research, industrial testing, medical and other fields. 1. Core functions and features of multifunctional sample stage (1) Multi dimensional adjustment of multifunctional sample stage Motion control: Supports precise movements such as X/Y/Z axis translation, rotation, and tilt, and is compatible with automatic scanning or manual fine-tuning. Environmental simulation: It can integrate modules such as temperature control (-196 ° C to several thousand degrees), humidity control, vacuum/atmosphere environment (such as inert gas, corrosive gas), etc. Force/electric/magnetic loading: Some models support the application of mechanical force, current, magnetic field, etc., used to study the performance of samples under extreme conditions. (2) Compatibility and Scalability of Multi functional Sample Stand Adapt to multiple analytical instruments Modular design allows users to add functions according to their needs, such as heating stations, cooling stations, fluid infusion systems, etc. (3) High precision and stability of multifunctional sample stage Nano level displacement accuracy, anti vibration design, suitable for in-situ observation or long-term experiments. Some models support in-situ characterization (such as real-time observation of sample changes during stretching, compression, and heating processes). (4) Automation and Intelligence of Multi functional Sample Stand Automated testing is achieved by controlling motion trajectories and environmental parameters through software. Integrated sensors and data acquisition system, real-time recording of sample reactions (such as deformation, resistance changes, etc.). 2. Typical application scenarios of multifunctional sample table: (1) Materials Science of Multi functional Sample Stand Study the performance of materials in high/low temperature, stress, and corrosive environments. In situ SEM/TEM observation of material deformation, phase transformation, or crystallization processes. (2) Biomedical multifunctional sample stage Cell culture and drug permeation experiments require temperature control, humidity control, and gas environment. Cooperate with microscopic imaging to observe the dynamic changes of living samples. (3) Electronics and Semiconductors for Multi functional Sample Stand Chip testing: Provides functions such as probe positioning, thermal shock, and electrical performance testing. Sample positioning and processing in photolithography or coating processes. (4) Chemical/Energy Research on Multi functional Sample Stand In situ monitoring of catalytic reactions (such as surface reactions under illumination and heating conditions). Battery electrode testing (simulating expansion/contraction during charging and discharging processes).

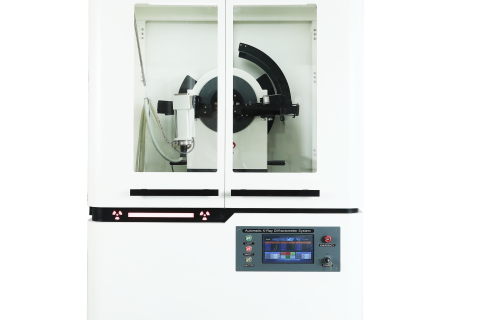

The multifunctional integrated measurement accessory of X-ray diffractometer (XRD) is a key component for achieving multi scene and multi-scale analysis. Through modular design, it can meet the needs of powder diffraction, small angle scattering, residual stress analysis, in-situ testing, etc. The following are common multifunctional integrated measurement accessories and their core functions: 1. The multifunctional integrated measurement accessory is a temperature and environmental control accessory (1) Function: Supports sample testing under high temperature, low temperature, and humidity control, used to study the crystal structure changes of materials under different temperature or humidity conditions. (2) Characteristics: Temperature range: from room temperature to 1500 ℃; Automatic temperature control and humidity regulation, suitable for in-situ catalysis, phase change analysis and other experiments. (3) Application: Phase transition of metal materials, analysis of polymer crystallinity, research on thermal stability of inorganic materials. 2. Automatic sampler and sample stage for multifunctional integrated measurement accessories (1) Function: Implement automatic switching and precise positioning of multiple samples to improve testing efficiency. (2) Characteristics: Supporting accessories such as sample rotation tables and micro diffraction tables for directional testing of complex samples; Collaborate with intelligent software to optimize measurement parameters and automatically identify sample configurations. (3) Application: Batch sample testing, thin film or micro area analysis. 3. Multi functional integrated measurement accessories suitable for two-dimensional detectors and high-speed one-dimensional detectors (1) Function: Support multi-dimensional data collection to enhance the analysis capability of complex samples. (2) Features: High speed one-dimensional detector, suitable for conventional powder diffraction; Two dimensional semiconductor array detector that can switch between zero dimensional, one-dimensional, or two-dimensional modes, expanding micro area or dynamic in-situ testing capabilities. (3) Application: 2D material crystal orientation analysis, in-situ reaction dynamic monitoring. 4. The multifunctional integrated measurement attachment is a residual stress and micro area diffraction attachment (1) Function: Conduct directional testing on the stress distribution or small areas on the surface of materials. (2) Features: Combining the θ/θ optical system with a microfocus X-ray source to achieve sub millimeter level micro diffraction; Non destructive measurement, used for stress analysis of metal workpieces and semiconductor devices. (3) Application: Fatigue testing of aerospace components, stress characterization of semiconductor thin films. 5. The multifunctional integrated measurement accessory is an intelligent calibration and automation control accessory (1) Function: Ensure testing accuracy and consistency through component recognition and automatic calibration technology. (2) Features: QR code automatic recognition attachment configuration, software guided optimal testing conditions; Fully automatic calibration program to reduce human operation errors. (3) Application: Complex attachment switching (such as high temperature+AXS mode), beginner friendly operation. The accessory design of modern X-ray diffractometers emphasizes modularity, intelligence, and automation. Through software and hardware collaboration, accessories can be quickly switched, parameters optimized, and data standardized. Future trends include higher precision micro area analysis capabilities, integrated solutions for in-situ dynamic testing, and intelligent accessory management systems driven by artificial intelligence.

The TDM-10 desktop X-ray diffractometer is a compact and high-precision phase analysis device. The following is a detailed introduction to the product: 1. Core functions and applications of TDM-10 desktop X-ray diffractometer (1) Phase analysis Suitable for qualitative and quantitative analysis of powder, solid, paste like materials, and thin film samples, it can identify the crystal structure, phase composition, and crystallinity in the samples. (2) Crystal structure analysis It can measure grain size, crystal orientation, macroscopic/microscopic stress, and structural properties of materials. (3) Industrial and Research Applications Widely used in fields such as geology, materials science, chemistry, biology, medicine, and nuclear industry, suitable for rapid laboratory testing and teaching demonstrations. 2. Technical characteristics of TDM-10 desktop X-ray diffractometer (1) Compact design and efficient performance Small size, light weight, low power consumption, easy to operate, suitable for desktop environments. Equipped with high-frequency and high-voltage power supply, the power can reach 1200W (refer to TDM-20 model), ensuring X-ray stability. (2) High precision measurement The measurement accuracy of diffraction peak position reaches 0.001 °, with excellent angular repeatability, meeting the requirements of high-precision analysis. By using the principles of Debye Scherrer geometry and Bragg's law, the crystal reflection signal is recorded through conical surface diffraction, achieving accurate phase identification. (3) Intelligent Control and Data Processing Computer controlled data acquisition, supporting real-time data acquisition and processing under Windows system, with an intuitive operating interface. Can be paired with array detectors (referring to the high-performance detector technology of TDM-20) to improve detection efficiency and sensitivity. 3. Applicable scenarios of TDM-10 desktop X-ray diffractometer (1) Research field Universities and research institutes are used for material research and development, crystal structure analysis, and characterization of nanomaterials. (2) Industrial applications Mineral identification, drug composition analysis, food safety testing (such as crystal impurity screening), etc. (3) Teaching Demonstration Easy to operate desktop device, suitable for student experimental teaching, covering the basic theory and practical operation of phase analysis. 4. Technical parameters of TDM-10 desktop X-ray diffractometer (1) Measurement accuracy: diffraction peak position accuracy of 0.001 ° (2) Control method: Computer control (Windows system) (3) Power supply: Low power design, high-frequency high-voltage power supply (4) Detector: Supports array detectors or proportional detectors (refer to TDM-20 accessories) (5) Sample stand: can be paired with a rotating sample stand or an automatic sample changer (optional accessory) 5. Product advantages of TDM-10 desktop X-ray diffractometer (1) High cost-effectiveness: Domestic equipment has outstanding performance and is much cheaper than imported equipment, making it suitable for laboratories with limited budgets. (2) Quick detection: Optimize calibration process, shorten testing time, and improve experimental efficiency. (3) Scalability: Supports multiple accessories (such as low-temperature cooling systems, in-situ battery accessories, etc.), which can be extended to special scenario analysis. 6. Related series and comparison of TDM-10 desktop X-ray diffractometer TDM-20 model: TDM-20 is an upgraded version of TDM-10, with higher power (1600W), new high-performance array detectors, support for automatic sample changers and other accessories, suitable for more complex industrial and scientific research needs. Other models: The Dandong Tongda TD series also includes high-resolution diffraction instruments such as TD-3500 and TD-3700, as well as TDF series crystal analyzers, covering multidimensional analysis needs. The TDM-10 desktop X-ray diffractometer has become the preferred equipment for laboratory phase analysis due to its compact design, high-precision measurement, and intelligent operation. It has a wide range of application scenarios, especially suitable for scientific research and industrial environments that require fast and accurate detection. If higher configuration is required, TDM-20 or other models in the same series can be considered.

X-ray irradiator is a scientific research equipment that uses X-rays to irradiate biological samples, materials, or small animals, and is widely used in fields such as biology, medicine, and materials science. 1. Core functions and technical principles of X-ray irradiation equipment (1) Functional positioning Biological research: used for DNA damage, cell mutagenesis, stem cell differentiation induction, tumor mechanism research, immunology and gene therapy experiments, etc. Medical applications: radiation disinfection, blood product processing, analysis of tumor cell apoptosis, pre-treatment for organ transplantation, etc. Materials and Environmental Science: Nanomaterial Modification, Food Radiation Quarantine, Soil Pollutant Analysis, etc. (2) Technical principles By accelerating electrons with high voltage to collide with metal targets, X-rays are generated; After optimization through filters, beam limiting devices, etc., the sample is irradiated to achieve targeted intervention by precisely controlling the dose rate, irradiation time, and range. 2. Key technical parameters of X-ray irradiation equipment (1) Radiation performance Tube voltage: 30-225kV (different models vary). Dose rate: 0.1-16Gy/minute, supporting precise and stepless adjustment. Dose uniformity: ≥ 95% (industry-leading level). Radiation angle and coverage area: The maximum radiation angle is 40 degrees, and the coverage diameter is up to 30cm. (2) Operation and Safety Design Intelligent control: touch screen operation interface, data export function (compatible with Excel). Safety protection: lead shielded cabinet, environmental dose<20 μ R/h (5cm away from equipment), multiple interlocks and fault alarms. Cooling system: Closed loop cooling technology extends the lifespan of X-ray tubes (up to 2000 hours). (3) Applicable sample types Cells, tissue organs, bacteria, mice, rats, etc., support irradiation of small animals in a conscious or anesthetized state. 3.Typical products and manufacturers of X-ray irradiation equipment Domestic representative: Dandong Tongda Technology Co., Ltd Advantages: Localization reduces procurement costs, simplifies operations (without the need for complex X-ray knowledge), and meets national safety standards. 4. Expansion of application fields for X-ray irradiation equipment (1) Biology and Medicine Cell research: inducing gene mutations, cell cycle regulation, signal transduction analysis. Tumor research: irradiation of tumor cell models to explore apoptosis mechanisms or radiation sensitivity. Preclinical studies: Whole body irradiation of small animals (such as mice) for research on hematopoietic system, immune response, etc. (2) Materials and Environmental Science Nanomaterial modification: changing the crystal structure or surface properties of materials through irradiation. Food quarantine: Non destructive detection of foreign objects, residual preservatives, or microbial inactivation. Nuclear waste disposal: Assist in analyzing the distribution of radioactive materials to ensure safe disposal. (3) Agriculture and Breeding Mutation breeding: Irradiating plant seeds or insects to accelerate gene mutations and screen for superior traits. 5. Development trends and challenges of X-ray irradiation equipment (1) Technical upgrade direction Intelligence: Combining AI algorithms to optimize dose distribution and experimental design. Safety: Reduce environmental radiation leakage and improve protection standards. Multi functional integration: such as integrating CT imaging and irradiation functions to achieve "detection processing" integration. (2) Industry challenges High precision dose control and stability require continuous optimization. More basic data is needed to support the differences in radiation sensitivity among biological samples. Overall, X-ray irradiation equipment is an indispensable tool in scientific research and industry. The X-ray irradiation equipment produced by Dandong Tongda Technology Co., Ltd. achieves a balance between performance and cost and is widely used in multiple fields. In the future, with technological iteration, its application scope will further expand to cutting-edge directions such as precision medicine and new material research and development.

The TDM-20 desktop X-ray diffractometer is a compact desktop device mainly used for material phase analysis and crystal structure research. 1. The core functions of TDM-20 desktop X-ray diffractometer Phase analysis of TDM-20: TDM-20 can perform qualitative/quantitative analysis on polycrystalline samples such as powders, solids, and paste materials. Crystal structure analysis of TDM-20: Based on the principle of X-ray diffraction, TDM-20 supports the analysis of crystal structures of metal samples, minerals, compounds, etc. 2. Technical characteristics of TDM-20 desktop X-ray diffractometer The high power and performance of TDM-20: using high-frequency high-voltage power supply, the power is increased to 1600W. Equipped with new high-speed array detectors or proportional detectors to improve data acquisition efficiency and accuracy. Convenient operation of TDM-20: The device is small in size and light in weight, suitable for compact laboratory spaces; Supports fast calibration and testing, with simple circuit control and easy installation and debugging. The accuracy and stability of TDM-20: the angle repeatability is as high as 0.0001 °, and the full spectrum diffraction angle linearity is ± 0.01 °. Scalability of TDM-20: TDM-20 can be equipped with a 6-digit automatic sample changer, a rotating sample stage, a low-temperature cooling system, and in-situ high/medium low temperature accessories to meet diverse testing needs. 3. Application scenarios of TDM-20 desktop X-ray diffractometer The research fields of TDM-20 include crystal structure characterization and phase transition analysis in materials science, geology, and pharmaceutical research. Industrial applications of TDM-20: pharmaceutical industry drug consistency assessment, mineral identification, petrochemical catalyst analysis, food safety testing (such as crystal composition determination). Education and National Defense of TDM-20: Rapid Phase Identification in University Teaching Experiments and National Defense Material Development. 4. Manufacturers and accessories of TDM-20 Manufacturer: Dandong Tongda Technology Co., Ltd. Optional accessories: one-dimensional array detector, proportional detector, 6-digit automatic sample changer, rotating sample stage, graphite bent crystal monochromator, etc. Overall, TDM-20, with its high power, high precision, and compact design, has become an efficient tool for laboratory phase analysis and is widely used in scientific research, industry, and teaching fields.

The TD-3500X-ray diffractometer (TD-3500XRD) is a high-performance analytical instrument produced by Dandong Tongda Technology Co., Ltd. It is mainly used for the analysis of crystal structure, phase composition, and material properties. 1. Core technical parameters of TD-3500X-ray diffractometer The X-ray source of TD-3500 diffractometer: Provide Cu K α or Mo K α target material selection, with adjustable tube voltage range of 10~60kV and tube current range of 2~80mA, supporting high-frequency and high-voltage solid-state generators or power frequency generators. Equipped with an imported Siemens PLC control system, it achieves automated light gate switching, tube pressure/flow regulation, and X-ray tube training functions with high stability. Angle measurement system of TD-3500X-ray diffractometer: Adopting a θ -2 θ vertical structure with a diffraction circle radius of 185mm (adjustable to 285mm), it supports testing of liquid, sol, powder, and block samples. The angular resolution reaches 0.0001 degrees, the step accuracy is 0.0001 degrees, and the angle measurement range is -5 °~165 ° (2 θ), suitable for high-precision crystal analysis. Detector of TD-3500X-ray diffractometer: Optional proportional detector (PC) or scintillation detector (SC), with a counting linear range of ≥ 700000 cps and background noise ≤ 1cps. Equipped with dual crystal monochromator technology, effectively suppressing the K α 2 component and improving the monochromaticity of the radiation. Control and software of TD-3500X-ray diffractometer: A human-machine interaction system based on imported PLC and true color touch screen, supporting parameter setting, real-time monitoring, and fault diagnosis. The software has functions such as phase diagram matching, stress analysis, and grain size calculation, and can generate standardized reports. 2. Technical characteristics and advantages of TD-3500X-ray diffractometer High precision and stability of TD-3500X-ray diffractometer: The angle measuring instrument adopts imported high-precision bearings and a fully closed-loop servo drive system, with automatic correction of motion errors and repeatability better than 0.0006 °. PLC modular design has strong anti-interference ability, supports long-term fault free operation, and can expand multiple functional accessories. Safety and protection of TD-3500X-ray diffractometer: The electronic lead door interlocking device achieves dual protection, with the light gate and lead door interlocked to ensure safe operation. Equipped with a circulating water cooling system (split or integrated), it automatically controls the water temperature and monitors the temperature of the X-ray tube to avoid blockage. Intelligent operation of TD-3500X-ray diffractometer: The touch screen displays the instrument status in real-time, supports parameter settings (such as scanning range, step size, sampling time), and remote fault diagnosis. Preset scanning modes (θ -2 θ, single crystal diffraction, thin film analysis) to meet different sample requirements. 3. The main application areas of TD-3500X-ray diffractometer Material analysis of TD-3500X-ray diffractometer: Qualitative/quantitative analysis of phases, identification of crystal structure, determination of grain size and crystallinity. Phase composition and stress analysis of materials such as semiconductors, ceramics, metals, polymers, etc. Research experiment of TD-3500X-ray diffractometer: Analysis of film orientation, phase transition research of catalyst/battery materials, and characterization of nano material structures. Biological crystals, macroscopic/microscopic stress measurement, and material temperature evolution analysis (requiring the use of a thermal analyzer). Typical user case of TD-3500X-ray diffractometer: Wuhan University of Technology (New Material Structure Research), Beijing Institute of Technology (Oxide Semiconductor Phase Transformation Research), Tongji University (Titanium Alloy Structure Analysis), etc. 4. Key points for operation and maintenance of TD-3500X-ray diffractometer Operation process of TD-3500X-ray diffractometer: Start up and preheat for 10-15 minutes → Sample preparation and fixation → Set scanning parameters (such as 2 θ range, step width, tube pressure/flow) → Start scanning → Data analysis. Support the combination of SEM and EDS to achieve comprehensive characterization of micro/nano structures and components. Widely used in materials science, chemistry, physics and other fields, it is the preferred tool for crystal structure and phase analysis.

The TD-3700 X-ray diffractometer is a high-performance and high-resolution X-ray analysis device, characterized by fast analysis, convenient operation, and strong safety. 1. Technical characteristics of TD-3700 X-ray diffractometer (1) Core configuration of X-ray diffractometer Equipped with a high-speed one-dimensional array detectoror SDD detector, using mixed photon counting technology, there is no noise interference, and the data acquisition speed far exceeds traditional scintillation detectors (with a speed increase of more than a hundred times), and it has high dynamic range (24 bits) and excellent energy resolution (687 ± 5 eV). Equipped with an imported programmable logic controller (PLC), it achieves automated control, low failure rate, strong anti-interference ability, and ensures stable operation of the high-voltage power supply for X-ray tubes. (2) Angle measuring system of X-ray diffractometer Adopting a θ/θ vertical angle measuring instrument structure, the sample is placed horizontally and supports testing of various forms of samples such as liquid, sol, powder, and block, to avoid samples falling into the bearing and causing corrosion. The scanning range of 2 θ angle is -110 °~161 °, with a minimum step of 0.0001 °, a repeatability of ± 0.0001 °, and an angle linearity of ± 0.01 °, suitable for high-precision structural analysis. Supports both conventional reflection mode and transmission mode, with the latter having higher resolution and suitable for trace samples (such as powders with low yields) and structural analysis. (3) The X-ray generation system of X-ray diffractometer The rated power can be selected from 3kW or 5kW, with a tube voltage range of 10~60 kV, a tube current of 2~80 mA, and a stability of ≤ 0.005%. Standard Cr/Co/Cu target material, suitable for different material analysis requirements. 2. Software and Control of TD-3700X-ray Diffraction Instrument (1) Control software for X-ray diffractometer Full Chinese interface, supports Windows XP system, can automatically regulate tube pressure, tube flow, and light switch, with X-ray tube aging training function. The application software provides processing functions such as peak searching, background subtraction, K α 2 stripping, integration calculation, spectrum comparison, etc. It supports inserting text annotations and various scaling operations. (2) Operation safety of X-ray diffractometer Dual protection system (linkage of light gate and lead gate), X-ray leakage rate ≤ 0.1 μ Sv/h, in compliance with national standards. Equipped with a circulating refrigeration system (split or integrated), automatic temperature control and monitoring of water flow rate, refrigerant pressure, etc., to avoid X-ray tube blockage. 3. Application scenarios of TD-3700X-ray diffractometer (1) The core function of X-ray diffractometer Qualitative/quantitative analysis of phases, analysis of crystal structure, determination of grain size and crystallinity. Macroscopic/microscopic stress detection, material orientation analysis (such as thin films, bulk samples). (2) Applicable fields of X-ray diffractometer Materials Science: Ceramics, Metals, Polymers, Superconducting Materials, etc. Environment and Geology: Soil, Rock, Mineral Analysis, and Petroleum Logging. Chemical and Pharmaceutical: Identification of Pharmaceutical Ingredients, Crystallinity Testing of Chemical Products. Other: food inspection, electronic materials, magnetic materials, etc. 4. Product advantages of TD-3700X-ray diffractometer (1) Modular design: The hardware system is modular and supports multiple accessories (such as optical accessories and special function software) that are plug and play, without the need to manually adjust the optical path. (2) Efficient and safe balance: One click operation simplifies the process, while reducing the risk of failure through PLC control, protection system, and automatic alarm functions (such as overcurrent protection and overtemperature warning). (3) Localization breakthrough: The TD series is the only XRD equipment in China that uses programmable controller technology, with performance comparable to imported models (such as D8 ADVANCE) and significantly reduced failure rates. The TD-3700X-ray diffractometer is a powerful and widely used X-ray diffractometer. Its high-performance detector, precise angle measuring system, powerful software functions, and wide range of application fields make it an important tool in scientific research and industrial production.

The TD-5000 X-ray single crystal diffractometer is a high-performance analytical instrument developed and produced by Dandong Tongda Technology Co., Ltd. The following is a detailed introduction to the instrument: 1. Structure and technical characteristics of single crystal diffractometer (1) Core technical support Adopting the four circle concentric angle measuring instrument technology ensures that the center position of the angle measuring instrument remains constant during rotation, improving data integrity and accuracy. Equipped with a hybrid pixel detector, combined with single photon counting and hybrid pixel technology, it achieves low noise and high dynamic range data collection, suitable for challenging sample analysis. High power X-ray generator (3kW or 5kW), supporting the selection of Cu/Mo and other target materials, with a focal size of 1 × 1mm and a divergence of 0.5~1 mrad, meeting different experimental requirements. (2) Modularization and operational optimization The whole machine adopts PLC control technology and modular design to achieve plug and play of accessories, reducing the calibration process. The touch screen monitors the instrument status in real-time, and the one click acquisition system simplifies the operation process. The electronic lead door interlocking device provides dual protection, with X-ray leakage ≤ 0.12 µ Sv/h (at maximum power). 2. Technical parameters of single crystal diffractometer (1) Accuracy and repeatability 2 θ angle repeatability accuracy: 0.0001 ° Minimum step angle: 0.0001 ° Temperature control range: 100K~300K, control accuracy ± 0.3K. (2) Detector performance Sensitive area: 83.8 × 70.0 mm ² Pixel size: 172 × 172 μ m ², pixel spacing error<0.03% Maximum frame rate: 20 Hz, readout time of 7 ms, energy range of 3.5~18 keV. (3) Other key parameters X-ray tube voltage: 10~60 kV (1 kV/step), current 2~50 mA or 2~80 mA. Liquid nitrogen consumption: 1.1~2 L/hour (low-temperature experiment). 3. Application fields of single crystal diffractometer (1) Main research direction Crystal structure analysis: Analyze the atomic arrangement, bond length, bond angle, molecular configuration, and electron cloud density of single crystal materials. Drug crystallography: Study the crystal morphology of drug molecules, evaluate stability and biological activity. New material development: Analyze the three-dimensional structure of synthesized compounds to support material performance optimization. Nanomaterials and Phase Transition Research: Exploring the Characteristics of Nanocrystals and the Mechanism of Material Phase Transition. (2) Typical users School of Materials Science and Technology at Huazhong University of Science and Technology, Zhejiang University, University of Science and Technology of China, and other universities. Research institutions such as China Aerospace Science and Technology Corporation and China Shipbuilding Industry Corporation. 4. After sales service of single crystal diffractometer Provide original spare parts, home maintenance, remote diagnosis, and software upgrade services. Regular calibration services (in compliance with international standards) and providing users with operational and application training. 5. Accessories and extended functions for single crystal diffractometer (1) Optional attachments Multi layer film focusing lens (divergence of 0.5~1 mrad). Low temperature device (liquid nitrogen cooling). (2) Compatible devices It can be used in conjunction with X-ray fluorescence spectrometer (XRF), scanning electron microscope (SEM), etc. to achieve multi-scale material analysis. Overall, as a high-end single crystal diffractometer, the performance of TD-5000 has approached international standards, making it particularly suitable for universities, research institutes, and high-end material development needs. For more details, please refer to the official website of Dandong Tongda Technology Co., Ltd.

Special corrugated ceramic tubes, metal ceramic tubes, and glass tubes for analytical instruments, suitable for various models of XRD, XRF, crystal analyzers, and orientation instruments at home and abroad. An X-ray tube is a vacuum electronic device that generates X-rays by high-speed electron impact on a metal target material. Its structure, principle, and application involve various technical characteristics. 1. Basic structure of X-ray tube (1) Cathode (electron emission source) Composed of tungsten filament, X-ray tube heats up and emits electrons after being powered on, and is wrapped around a focusing cover (cathode head) to control the direction of the electron beam. The filament temperature is about 2000K, and the electron emission is regulated by current. (2) Anode (target material) Usually high melting point metals (such as tungsten, molybdenum, rhodium, etc.) are used to withstand high-energy electron bombardment and generate X-rays. Contains anode head (target surface), anode cap, glass ring, and anode handle, responsible for heat dissipation (through radiation or conduction) and absorption of secondary electrons. (3) Vacuum shell and window Glass or ceramic shell maintains a high vacuum environment (not less than 10 ⁻⁴ Pa) to avoid electron scattering. Window materials require low X-ray absorption, commonly using beryllium sheets, aluminum, or Lindemann glass. 2. Working principle of X-ray tube (1) Electron Acceleration and Impact The electrons emitted by the cathode filament are accelerated by high voltage (in the range of kilovolts to megavolts) and collide with the anode target material. The process of converting electronic kinetic energy into X-rays includes: Bremsstrahlung: Continuous spectrum X-rays released when electrons decelerate or deflect. Characteristic radiation: X-rays (such as Kα and Kβ lines) released by electron transitions in the inner layer of the target material. (2) Energy Conversion and Efficiency Only about 1% of the electron energy is converted into X-rays, and the remaining is dissipated in the form of heat, requiring forced cooling (such as a rotating anode design). 3. Classification and application scenarios of X-ray tubes (1) By generating electronic means Inflatable tube: an early type that relies on gas ionization to generate electrons, with low power and short lifespan (now obsolete). Vacuum tube: Modern mainstream, high vacuum environment improves electronic efficiency and stability. (2) By purpose In the medical field, diagnostic (such as dental and breast examinations) and therapeutic (such as radiotherapy) X-ray tube often use rotating anodes to increase power density. Industrial testing: non-destructive testing, material structure analysis, etc., with a focus on high penetration (hard X-rays). (3) According to the cooling method Fixed anode: simple structure, suitable for low-power scenarios. Rotating anode: The target surface rotates at high speed (up to 10000 revolutions per minute) to improve heat dissipation and support high-power output. 4. Performance characteristics and limitations of X-ray tubes (1) Advantages Low cost, small size, easy operation, suitable for routine medical and industrial testing. Flexible adjustment of target materials (such as tungsten, molybdenum, copper) to meet different energy requirements. (2) Limitations Poor brightness and collimation, large X-ray divergence angle, requiring additional collimators. The energy spectrum is continuous and contains characteristic lines, requiring filtering or monochromatization (such as using nickel filters to remove Kβ lines). 5. Comparison between X-ray tubes and synchrotron radiation sources (1) Brightness and flux X-ray tube: Low brightness, suitable for routine testing. Synchrotron radiation light source: with a brightness 106~1012times higher, suitable for cutting-edge research such as nanoimaging and protein crystallography. (2) Spectral characteristics X-ray tube: Discrete characteristic lines+continuous spectrum, energy range limited by acceleration voltage. Synchrotron radiation: wide continuous spectrum (from infrared to hard X-rays), precisely tunable. (3) Time characteristics X-ray tube: Continuous or microsecond level pulses (rotating target). Synchrotron radiation: Femtosecond level pulses, suitable for studying dynamic processes such as chemical reactions. 6. Technical parameters of X-ray tube (1) Optional target material types: Cu, Co, Fe, Cr, Mo, Ti, W, etc (2) Focus type: 0.2 × 12mm2 or 1 × 10mm2 or 0.4 × 14mm2 (fine focus) (3) Larger output power: 2.4kW or 2.7kW Overall, X-ray tube dominate in fields such as medical diagnosis and industrial testing due to their practicality and economy, but are limited by performance bottlenecks. For scenes that require high resolution and high brightness (such as cutting-edge scientific research), advanced technologies such as synchrotron radiation sources need to be relied upon. Future development directions include improving energy conversion efficiency, optimizing heat dissipation structures, and developing miniaturized X-ray sources.

The rotating sample holder is an experimental device used for precise control of sample orientation, widely used in fields such as X-ray diffraction (XRD), spectroscopic analysis, and material testing. By rotating the sample, preferred orientation can be eliminated, measurement accuracy and repeatability can be improved. 1. The core function of the rotating sample holder (1) Eliminating preferred orientation: By rotating the sample plane (β axis), diffraction errors caused by coarse grains or texture are reduced, ensuring the reproducibility of diffraction intensity. (2) Multi position measurement: Conduct multi angle measurements on uneven samples (such as grains), average the data at different positions, and improve the accuracy and repeatability of the results. (3) Automated operation: Some devices support automatic rotation and sample change to improve testing efficiency (such as XRD fully automatic rotating sample holder). 2. Technical characteristics of rotating sample holder (1) Structural design: Drive mode: precise rotation is achieved through mechanisms such as motors, shafts, gears and racks, and some equipment is equipped with servo motors and encoders to correct the speed. Clamping device: The sample is fixed by a compression clamp, card slot, or clamping block, and the inner side is partially clamped with a rubber layer to adapt to different materials. Rotation parameters: The rotation speed can reach 1-60RPM, with a minimum step width of 0.1 º, and supports continuous or step modes. (2) Adaptability: Can be installed in XRD instruments, optical/electrical testing systems, etc., supporting multiple sample holders (such as reflective probes, in-situ battery accessories, etc.). Some devices support 360°rotation and are compatible with various measurement requirements such as optics and electronics. 3. Application scenarios of rotating sample holder (1) X-ray diffraction (XRD): Used for analyzing samples with texture or crystallography (such as metal materials, thin films), to eliminate the influence of preferred orientation on diffraction results. The fully automatic model can improve the efficiency of multi sample testing, reduce the number of door opening and closing times, and extend the lifespan of equipment. (2) Spectral analysis and material testing: Used for measuring uneven samples (such as grains) with reflective probes, by rotating and averaging spectral data at different positions. Adapt to in-situ high and low temperature environments, and support complex experimental conditions. (3) Multi functional experiment: By combining probes, electrical or optical sample holders, comprehensive testing of electrical characteristics, surface morphology, and other features can be achieved. The rotating sample holder solves the measurement error problem caused by the preferred orientation of traditional fixed sample stages by accurately controlling the sample orientation. At the same time, its automation and multi scene adaptability make it a key tool in fields such as XRD and spectral analysis. The specific selection needs to be matched with the corresponding model based on experimental requirements such as rotation accuracy, sample type, and automation level.

In situ medium and low temperature accessories are experimental equipment accessory used for material analysis, mainly used for in-situ testing in low or medium low temperature environments. Combined with vacuum environment, temperature control, and special window material design, it is widely used in fields such as chemistry, materials science, and catalytic research. 1. Core functions and technical parameters of in-situ medium and low temperature accessories (1) Temperature range and control accuracy Supports a temperature range of -196 ℃ to 500 ℃ in a vacuum environment (such as liquid nitrogen refrigeration), with a temperature control accuracy of ± 0.5 ℃. Some models can cover temperatures from -150 ° C to 600 ° C, suitable for a wider range of experimental needs. (2) Refrigeration method and cooling system Using liquid nitrogen refrigeration, with a liquid nitrogen consumption of less than 4L/h, and maintaining a stable temperature through a deionized water circulation cooling system. Optional low-temperature liquid nitrogen cooling system (such as Cryostream series). (3) Window Materials and Structural Design The window material is mostly polyester film (such as TD series), and some infrared configurations use KBr or SiO2 windows. The structure includes a high-pressure resistant design (such as 133kPa) and is equipped with multiple gas inlets/outlets, suitable for in-situ reactions or atmosphere control. 2. Application fields of in-situ medium and low temperature accessories (1) Material research Used for in-situ testing of X-ray diffractometers (such as TD-3500) to study changes in crystal structure and phase transition processes at low temperatures. Support research on heterogeneous catalysis, gas-solid interactions, photochemical reactions, etc. (2) Electrochemical and Battery Research It can be extended to in-situ battery accessories to test composites in electrochemical systems (such as carbon, oxygen, nitrogen, sulfur, etc.), with a temperature resistance of up to 400 ℃. (3) Industry Applications The products of Dandong Tongda Technology (TD series) have been applied in the fields of chemistry, chemical engineering, geology, metallurgy, etc., and exported to countries such as the United States and Azerbaijan. 3. Typical products and brands of in-situ medium and low temperature accessories Dandong Tongda Technology (TD Series) The accessories for X-ray diffractometers such as TD-3500 and TD-3700 emphasize high-precision temperature control (± 0.5 ℃) and efficient liquid nitrogen refrigeration. Suitable for diffuse reflectance spectroscopy measurement, providing stainless steel reaction chamber, multi window configuration (FTIR or UV Vis compatible), supporting high vacuum to 133kPa environment. Overall, in situ medium and low temperature accessories have become an important tool for material in situ analysis through precise temperature control, vacuum environment, and window design adapted to different instruments. They play an irreplaceable role in the study of low-temperature crystal structures and exploration of catalytic reaction mechanisms.