Unlock new dimensions of nanoscale material analysis

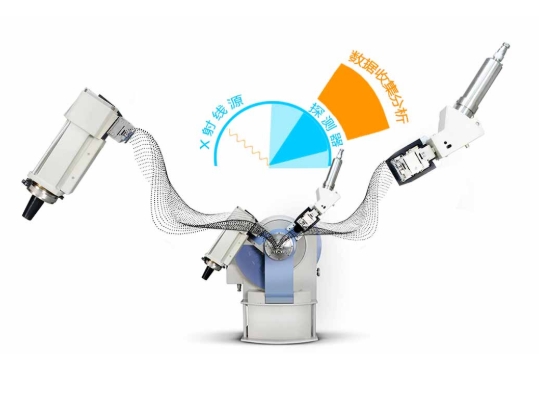

2025-05-13 14:34The TD-3500X-ray diffractometer (TD-3500XRD) is a high-performance analytical instrument produced by Dandong Tongda Technology Co., Ltd. It is mainly used for the analysis of crystal structure, phase composition, and material properties.

1. Core technical parameters of TD-3500X-ray diffractometer

The X-ray source of TD-3500 diffractometer:

Provide Cu K α or Mo K α target material selection, with adjustable tube voltage range of 10~60kV and tube current range of 2~80mA, supporting high-frequency and high-voltage solid-state generators or power frequency generators. Equipped with an imported Siemens PLC control system, it achieves automated light gate switching, tube pressure/flow regulation, and X-ray tube training functions with high stability.

Angle measurement system of TD-3500X-ray diffractometer:

Adopting a θ -2 θ vertical structure with a diffraction circle radius of 185mm (adjustable to 285mm), it supports testing of liquid, sol, powder, and block samples. The angular resolution reaches 0.0001 degrees, the step accuracy is 0.0001 degrees, and the angle measurement range is -5 °~165 ° (2 θ), suitable for high-precision crystal analysis.

Detector of TD-3500X-ray diffractometer:

Optional proportional detector (PC) or scintillation detector (SC), with a counting linear range of ≥ 700000 cps and background noise ≤ 1cps. Equipped with dual crystal monochromator technology, effectively suppressing the K α 2 component and improving the monochromaticity of the radiation.

Control and software of TD-3500X-ray diffractometer:

A human-machine interaction system based on imported PLC and true color touch screen, supporting parameter setting, real-time monitoring, and fault diagnosis.

The software has functions such as phase diagram matching, stress analysis, and grain size calculation, and can generate standardized reports.

2. Technical characteristics and advantages of TD-3500X-ray diffractometer

High precision and stability of TD-3500X-ray diffractometer:

The angle measuring instrument adopts imported high-precision bearings and a fully closed-loop servo drive system, with automatic correction of motion errors and repeatability better than 0.0006 °. PLC modular design has strong anti-interference ability, supports long-term fault free operation, and can expand multiple functional accessories.

Safety and protection of TD-3500X-ray diffractometer:

The electronic lead door interlocking device achieves dual protection, with the light gate and lead door interlocked to ensure safe operation. Equipped with a circulating water cooling system (split or integrated), it automatically controls the water temperature and monitors the temperature of the X-ray tube to avoid blockage.

Intelligent operation of TD-3500X-ray diffractometer:

The touch screen displays the instrument status in real-time, supports parameter settings (such as scanning range, step size, sampling time), and remote fault diagnosis. Preset scanning modes (θ -2 θ, single crystal diffraction, thin film analysis) to meet different sample requirements.

3. The main application areas of TD-3500X-ray diffractometer

Material analysis of TD-3500X-ray diffractometer:

Qualitative/quantitative analysis of phases, identification of crystal structure, determination of grain size and crystallinity.

Phase composition and stress analysis of materials such as semiconductors, ceramics, metals, polymers, etc.

Research experiment of TD-3500X-ray diffractometer:

Analysis of film orientation, phase transition research of catalyst/battery materials, and characterization of nano material structures.

Biological crystals, macroscopic/microscopic stress measurement, and material temperature evolution analysis (requiring the use of a thermal analyzer).

Typical user case of TD-3500X-ray diffractometer:

Wuhan University of Technology (New Material Structure Research), Beijing Institute of Technology (Oxide Semiconductor Phase Transformation Research), Tongji University (Titanium Alloy Structure Analysis), etc.

4. Key points for operation and maintenance of TD-3500X-ray diffractometer

Operation process of TD-3500X-ray diffractometer:

Start up and preheat for 10-15 minutes → Sample preparation and fixation → Set scanning parameters (such as 2 θ range, step width, tube pressure/flow) → Start scanning → Data analysis. Support the combination of SEM and EDS to achieve comprehensive characterization of micro/nano structures and components. Widely used in materials science, chemistry, physics and other fields, it is the preferred tool for crystal structure and phase analysis.