- Home

- >

- News

- >

- Product News

- >

News

In X-ray diffraction analysis, thin film samples present significant challenges due to their extremely thin thickness, weak signals, and typical attachment to a substrate. Traditional testing methods are prone to interference from substrate signals, causing the signals from the thin film itself to be masked or distorted. The core design of the parallel beam thin film accessory lies in increasing the length of the grating slices to filter out more scattered rays. This approach offers two significant advantages: Reduces Substrate Signal Interference: Effectively suppresses non-target signals originating from the sample substrate. Enhances Thin Film Signal Strength: Makes the analytical signals from the target thin film more prominent, thereby yielding clearer and more accurate analysis results. Application Fields: The parallel beam thin film accessory is primarily applied in cutting-edge fields such as environmental protection and electronics. In these industries, the performance of thin film materials often directly determines the quality of the final product. For example, in the electronics industry, various functional thin films are widely used in products like semiconductor devices, display screens, and solar cells. The crystal structure, orientation, and stress state of the thin films significantly impact their electrical, optical, and mechanical properties. By utilizing the parallel beam thin film attachment, researchers can evaluate these key parameters more precisely, providing robust support for product development and quality control. Dandong Tongda Science and Technology Co., Ltd. is a National High-Tech Enterprise specializing in the production of X-ray analysis instruments and non-destructive testing equipment. It was also the undertaking unit of the "National Major Scientific Instrument and Equipment Development Project" initiated by the Ministry of Science and Technology in 2013. Tongda Science and Technology has completed the serialization of its two main product lines: analytical instruments and non-destructive testing instruments.

The AI fully automated X-ray diffractometer deeply integrates the high-precision manipulation of a robotic arm based on a portable diffractometer. Compared to traditional diffractometers, it significantly reduces manual intervention, making it suitable for R&D scenarios requiring high-throughput and high-repeatability testing. It can be remotely controlled via mobile phone or APP, featuring automatic door opening and closing technology. With autonomous sampling and analysis capabilities, it offers precision and convenience.

Fiber Accessories utilize the X-ray diffraction (transmission) method to analyze the unique crystal structure of fibers. Parameters such as crystallinity and full width at half maximum (FWHM) are used to determine the orientation degree of the sample. Main Functions and Features of Fiber Accessories: Maintaining Fiber Orientation: This is the most critical aspect. Fibers typically exhibit high anisotropy, with crystals preferentially aligned along the fiber axis. Fiber Accessories can straighten and secure fiber bundles, preserving their original orientation to measure orientation degree and distribution. Adapting to Different Sample Forms: Single Fiber: Extremely thin, requiring special clamps or frames for fixation. Fiber Bundle: Multiple fibers arranged in parallel; Fiber Accessories must align and tension them uniformly. Fiber Fabric: Materials like cloth require a flat frame to stretch them taut. Enabling Special Testing Modes: Transmission Mode: Suitable for thin fiber bundles or single fibers. Fiber Accessories include a dedicated frame to tension the fiber, allowing X-rays to penetrate the sample directly. Reflection Mode: Used for thicker fiber bundles or fabrics. Fiber Accessories provide a flat sample surface for this mode. Fiber Sample Holder: This is a simple metal or plastic frame equipped with slots or knobs. During operation, both ends of the fiber bundle are fixed to the holder, and knobs are rotated to tension the fiber, keeping it straight and parallel. The entire holder can be placed in the XRD goniometer for testing, similar to a standard sample. In summary, Fiber Accessories for XRD are specialized sample fixation devices designed for testing fibrous samples with anisotropic structures. Their core function is to maintain and regulate fiber orientation, while advanced versions may support in-situ stretching and other functionalities, providing critical insights into the orientation of crystal structures in fibers.

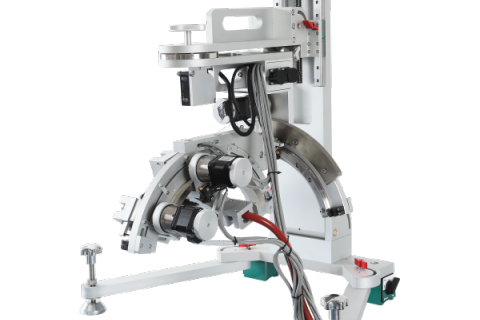

In the field of materials science research, precise measurement serves as the key to unlocking material properties. The multi-functional integrated measurement accessory developed by Dandong Tongda Science and Technology Co., Ltd. is a high-precision tool designed to enhance X-ray diffraction analysis capabilities. This multi-functional integrated measurement accessory is specifically designed for installation on wide-angle goniometers. Its core mission is to accurately analyze plate materials, bulk materials, and thin films deposited on substrates. The accessory can perform various measurement tasks, including crystal phase detection, orientation degree analysis, and stress testing. It supports texture analysis, residual stress determination, and in-plane structure testing of thin films, providing comprehensive data support for materials research. The core technical features of this accessory are reflected in its multi-axis coordinated precision mechanical system and highly adaptable measurement methods. The multi-functional integrated measurement accessory supports pole figure measurements using either transmission or reflection methods, offering flexibility for different samples and testing requirements. For stress testing, it can employ both the side-inclination method and the normal-inclination method. For thin film samples, the accessory also enables in-plane rotation testing, allowing for in-depth analysis of film structures. Its precision mechanical system ensures high measurement accuracy and repeatability, with minimum step increments of 0.001° (for rotation axes) and 0.001mm (for translation axes). The application scope of the multi-functional integrated measurement accessory is extremely broad, covering almost all advanced manufacturing and R&D fields that require material structure analysis. In the field of metal materials, it is used for evaluating the collective organization of metals such as rolled plates; in ceramics, it focuses on assessing ceramic orientation. For thin film materials, the accessory can analyze the preferred crystal orientation of film samples and test the residual stress of multilayer films (evaluating properties such as film peeling). It can also analyze surface oxidation and nitridation films on high-temperature superconducting material films and metal plates, as well as multilayer films on glass, silicon, and metal substrates. Notably, it can also be applied to the analysis of macromolecular materials, paper, lens plating materials, and more, demonstrating its interdisciplinary application potential. Measurement Accessory

In the fields of materials science and industrial testing, precise sample analysis relies on reliable instruments. The rotating sample stage produced by Dandong Tongda Technology Co., Ltd. is precisely such a critical accessory dedicated to enhancing the quality of X-ray diffraction (XRD) analysis. In X-ray diffraction analysis, the characteristics of the sample itself often pose challenges. For example, when the grains are excessively coarse, the material exhibits significant texture (or "preferred orientation," meaning the grains are not randomly arranged), or the sample has specific crystal habits (crystal growth patterns), obtaining diffraction data that is statistically representative and truly reflects the overall material properties becomes difficult. When measuring such samples with traditional static sample stages, the diffraction intensity may be distorted due to the aforementioned factors, affecting the accuracy of phase identification, texture analysis, and other evaluations. The core design philosophy of Tongda Technology's rotating sample stage is to address these challenges by enabling smooth rotation of the sample within its own plane. Core Function: Eliminating Orientation Errors and Enhancing Data Reliability The working principle of this rotating sample stage is intuitive and effective. By driving the sample to rotate continuously or in a stepwise manner, it ensures that the X-ray beam covers more grains with different orientations on the sample during irradiation. The main advantages of this approach are: Effective Reduction of Measurement Errors: Through the rotation averaging effect, it significantly mitigates measurement deviations caused by coarse grains or preferred orientation, making the diffraction data more representative of the material's overall properties. Ensuring Result Reproducibility: Whether the sample itself has texture or not, it guarantees good reproducibility of diffraction intensity across multiple measurements or between different laboratories, enhancing the reliability and comparability of data. Simplified Sample Preparation Requirements: It reduces the stringent demands for perfect sample preparation to a certain extent, improving analysis efficiency. Technical Specifications: Precision Control and Flexible Adaptability The rotating sample stage from Dandong Tongda Technology offers the following key technical parameters to meet the rigorous demands of scientific research and industrial testing: ParameterDescription Rotation Methodβ-axis (sample rotates within its own plane) Rotation Speed Range1 ~ 60 RPM (revolutions per minute) Adjustable based on experimental requirements Stepping PrecisionMinimum step width: 0.1º Supports high-precision positioning scanning Operation ModesConstant-speed rotation (for sample scanning), stepping, continuous, and other modes Adapts to various testing workflows and data acquisition needs Typical ApplicationsQuality control and R&D in industries such as environmental protection and electronics CompatibilityPrimarily used as an accessory for X-ray diffraction spectrometers (XRD) Application Scenarios: Serving the Environmental Protection and Electronics Industries This rotating sample stage is not merely a "showpiece" in the laboratory; it directly serves industries with high requirements for material analysis, such as environmental protection and electronics. In areas such as quality control, new product development, and failure analysis in these fields, it assists engineers and researchers in conducting more accurate phase analysis on samples of various forms, including powders, bulk materials, and thin films, ensuring the authenticity and reliability of data.

In the field of lithium-ion battery research and development, understanding the dynamic changes in the microstructure of electrode materials during charge and discharge processes is crucial. Traditional offline detection methods cannot capture these changes in real time, while the emergence of in situ characterization techniques provides researchers with a powerful tool. Leveraging its expertise in X-ray diffraction (XRD) technology, Dandong Tongda Technology Co., Ltd. has developed an in situ battery accessory for battery research, offering an efficient window to explore the reaction processes inside the "black box" of batteries. Technical Principle: Dynamically Monitoring Microscale Changes in Battery Materials The core design goal of Dandong Tongda's originally battery accessory is to enable real-time monitoring of the evolution of the crystal structure of electrode materials using X-ray diffraction (XRD) technology while the battery is operating normally (during charge and discharge). This accessory typically needs to work in synergy with an electrochemical testing system (such as the LAND battery test system) and an X-ray diffractometer (such as Tongda Tech's TD-3500 model). It forms a specialized battery chamber that allows X-rays to penetrate and probe the electrode materials of the battery during operation. The key lies in the design of window materials (such as beryllium windows) with extremely low X-ray absorption rates on the battery components, ensuring effective incidence and emission of X-rays. Simultaneously, the accessory integrates necessary electrodes, insulation, and sealing components to ensure normal electrochemical reactions and maintain excellent sealing during testing. Key Functions and Application Value The value of this in situ battery accessory lies in its ability to help researchers intuitively and dynamically observe a series of microscopic changes in electrode materials during battery charge and discharge processes: Real-Time Observation of Phase Transition Processes: Many electrode materials undergo phase transitions during lithium-ion intercalation and deintercalation. In situ XRD can capture the formation, disappearance, and transformation of these phases in real time, which is critical for understanding the battery's reaction mechanisms. Monitoring Lattice Parameter Changes: By precisely tracking the shifts in XRD diffraction peaks, subtle changes in lattice parameters can be calculated, reflecting the expansion and contraction of the lattice. This is closely related to battery performance metrics such as voltage platforms and cycle life. Unveiling Capacity Decay Mechanisms: Capacity decay during battery cycling is often related to structural degradation of electrode materials, side reactions, and other factors. In situ monitoring can correlate electrochemical performance degradation with structural changes, providing direct insights for improving battery materials and optimizing design. Accelerating New Material Development: For evaluating novel electrode materials, in situ XRD technology can quickly provide key information on structural stability and reaction pathways, speeding up the R&D process.

As a well-known enterprise in the field of domestic precision instruments, Dandong Tongda Technology Co., Ltd. has launched a series of multi-function sample holder products. With high precision, modular design, and extensive application scenarios, these products have become one of the core equipment in material analysis, X-ray diffraction (XRD), and other fields. Core Functions: Meeting Diverse Analytical Needs Material Structure Analysis: Used for crystalline phase detection, orientation degree (texture) analysis, and residual stress testing, supporting the analysis of materials such as metals, ceramics, and thin films. In-plane rotation (β-axis) eliminates preferred orientation, ensuring the reproducibility of diffraction intensity data. Environmental Simulation Function: Optional high-temperature, low-temperature, or vacuum atmosphere modules (e.g., liquid nitrogen temperature control devices) support variable temperature testing from -196°C to 1000°C, meeting special requirements for high-temperature superconducting materials, metal surface treatment, and more. Automation and Intelligence: Supporting software enables automatic scanning, multi-point measurement, and data linkage analysis, improving detection efficiency. Application Fields: From Scientific Research to Industrial Testing Dandong Tongda sample holder are widely used in the following fields: Materials Science: Texture evaluation of rolled metal sheets, orientation analysis of ceramics, and residual stress testing of thin films. Semiconductor Industry: Analysis of multilayer films on silicon substrates (e.g., magnetic films, hardened coatings). Energy and Environmental Protection: Microstructural research on high-temperature superconducting films, battery materials, and catalysts. Higher Education and Scientific Research: Experimental teaching and research projects in crystallography, quantitative phase analysis, and more. Conclusion: An Indispensable Tool for Material Microanalysis The Dandong Tongda Multi-Function Sample Holder, with its high-precision motion control, modular flexibility, and broad environmental adaptability, has become an indispensable tool for material microanalysis. Its technical advantages are deeply rooted in the company's years of accumulated expertise in X-ray diffraction technology, combining research-grade precision with industrial-grade reliability to help users unlock the secrets of material properties at the microscopic scale. The multi-function sample stage serves as the "hands and feet" of modern precision observation and measurement, precisely presenting samples within the "field of view" of analytical instruments. Its selection directly determines the feasibility, efficiency, and reliability of experiments. Understanding its basic principles, functional classifications, and technical specifications is key to selecting and effectively utilizing this equipment.

Non-Destructive Testing (NDT) is an indispensable quality assurance technology in modern industry. It enables the detection of internal defects, structures, and property conditions of materials by utilizing characteristics such as acoustic, optical, magnetic, and electrical properties—all without damaging or affecting the performance of the tested object. Compared to destructive testing, NDT has the following characteristics: First, it is non-destructive, as it does not impair the performance of the test object. Second, it is comprehensive. Since the testing is non-destructive, it allows for 100% full inspection of the test object when necessary, which is impossible with destructive testing. Third, it is full-process applicable. Destructive testing is generally only suitable for raw materials, such as tensile, compression, and bending tests commonly used in mechanical engineering. Destructive testing is conducted only on raw materials for manufacturing. For finished products and in-service equipment, destructive testing cannot be performed unless they are no longer intended for use. In contrast, NDT does not damage the test object’s performance, making it suitable for full-process testing, from raw materials and intermediate manufacturing stages to final products, as well as for in-service equipment. Among the many manufacturers of non-destructive testing equipment, Dandong Tongda Technology Co., Ltd. has developed a variety of NDT instruments that approach or achieve internationally advanced levels, thanks to its solid technical expertise and innovative capabilities. Technical Features: Portability, Safety, and Intelligence Tongda Technology's NDT Portable X-ray Welding Testing Machine exhibit several outstanding features. Their X-ray generators adopt an anode grounding and fan-forced cooling design, making them compact, lightweight, portable, and easy to operate. In terms of safety performance, the equipment is equipped with a delayed exposure function, effectively ensuring operator safety. The devices operate on a 1:1 work-rest cycle, with a rational duty cycle design that ensures detection efficiency while extending the equipment’s service life. The company’s products incorporate Programmable Logic Controller (PLC) technology and a modular design concept, enhancing automation, improving anti-interference capabilities, and ensuring an extremely low failure rate. Application Areas: Wide Adoption Across Multiple Industries Tongda Technology's NDT Portable X-ray Welding Testing Machine are suitable for various industrial sectors, including national defense, shipbuilding, petroleum, chemicals, machinery, aerospace, and construction. These instruments are used to inspect the welding quality of materials and components such as ship hulls, pipelines, high-pressure vessels, boilers, aircraft, vehicles, and bridges, as well as the internal quality of various lightweight metals, rubber, ceramics, and other materials.

Dandong Tongda XAFS Spectrometer: A Material Structure Analysis Tool for the Laboratory Precise analysis of atomic material structure without dependence on synchrotron radiation sources. X-ray Absorption Fine Structure (XAFS) spectroscopy serves as an important technique for investigating the local atomic and electronic structures of materials, with broad applications in catalysis, energy research, and materials science. Conventional XAFS methodology primarily relies on synchrotron radiation sources, which presents challenges including limited beam availability, complex application procedures, and the necessity to transport samples to large-scale scientific facilities for analysis. The X-ray Absorption Fine Structure developed by Dandong Tongda Technology Co., Ltd. aims to integrate this sophisticated analytical capability into standard laboratory environments. Core Advantages and Practical Value This instrument's design addresses several critical challenges researchers encounter: Laboratory-Based Alternative to Synchrotron Radiation: Eliminates the traditional dependency on synchrotron radiation sources, enabling researchers to conduct routine XAFS testing efficiently within their own laboratory settings, thereby significantly enhancing research productivity. In-Situ Testing Capabilities: Supports integration of various in-situ sample chambers (e.g., electrochemical, temperature-variable), enabling real-time monitoring of dynamic changes in material local atomic structure under simulated operational conditions (such as catalytic reactions or battery charge/discharge processes), providing valuable insights into reaction mechanisms. Automated Operation for Enhanced Efficiency: An 18-position sample turret enables automatic sample changing, facilitating continuous automated measurement of multiple samples and unmanned operation, thereby streamlining batch sample screening and extended in-situ experiments. Broad Application Scope The TD-XAFS spectrometer finds applications across numerous fields requiring detailed investigation of material local structures: New Energy Materials: Analysis of valence state changes and structural stability in lithium-ion battery electrode materials during charge/discharge processes; investigation of coordination environments at catalytic active sites in fuel cells. Catalysis Science: Particularly suitable for studying precise coordination structures of nanocatalysts and single-atom catalysts, active site characteristics, and their interactions with support materials, even at low metal loadings (<1%). Materials Science: Investigation of disordered structures, amorphous materials, surface/interface effects, and dynamic phase transition processes. Environmental Science: Analysis of valence states and coordination structures of heavy metal elements in environmental samples (e.g., soil, water), crucial for assessing toxicity and mobility. Biological Macromolecules: Study of electronic structures and geometric configurations of metal active centers in metalloproteins and enzymes. Summary Dandong Tongda's TD-XAFS spectrometer represents a high-performance domestic benchtop testing platform designed for universities, research institutions, and corporate R&D centers. It successfully incorporates synchrotron-level capabilities into conventional laboratories, substantially reducing the accessibility barrier to XAFS technology. The instrument provides researchers with convenient, efficient, and flexible tools for microscopic material structure analysis, serving as a practical solution for scientists exploring the microscopic world of matter.

In research fields such as life sciences, radiation biology, and pest control technology, precise, safe, and controllable irradiation methods are fundamental to many critical experiments. Leveraging its expertise in X-ray technology, Dandong Tongda Technology Co., Ltd. has developed the WBK-01 X-ray Irradiator, designed to provide a modern alternative to traditional radioactive isotope sources for various laboratories. I. Core Principle and Design Purpose The equipment operates by accelerating electrons through a high-voltage electric field to strike a metal target (e.g., a gold target), thereby generating high-energy X-rays. This design of an "electrically generated radiation source" fundamentally avoids the use of radioactive isotopes like Cobalt-60 (Co-60) or Cesium-137 (Cs-137), eliminating the long-term custody, substantial decommissioning costs, and potential safety hazards associated with source materials. II. Core Product Features High Safety: No Radiation When Powered Off: X-rays are only generated when the equipment is powered on and operating. There is no residual radiation after operation, significantly reducing laboratory security and management costs. Multiple Safety Interlocks: Equipped with multiple safety protection features including door-operation interlock, emergency stop, and overdose protection, ensuring the safety of operators and the environment. Precise Control and Good Reproducibility: Utilizes a digital control system, allowing users to precisely set irradiation parameters—including voltage (kV), current (mA), and irradiation time—via a touchscreen interface. The system enables stable dose output, ensuring uniformity in experimental conditions and reproducibility of results. Easy Operation and Simple Maintenance: The user interface is simple and intuitive, easy to learn and operate, lowering the barrier to use. Compared to isotope sources which require regular replacement and decay monitoring, the main maintenance for this equipment focuses on the periodic replacement of the X-ray tube, resulting in relatively fixed and manageable long-term maintenance costs. Flexible Sample Compatibility: The irradiation chamber is designed to accommodate various samples, from cell culture dishes and multi-well plates to small animals (e.g., fruit flies, mosquitoes, or mice). The sample stage can be designed to rotate, ensuring uniformity in radiation dose distribution. III. Main Application Scenarios Biomedical Research: Used for creating immunodeficient animal models (e.g., ablating bone marrow cells in mice), inducing cell apoptosis, synchronizing cell cycles, oncology research, and pre-treatment for stem cell transplantation. Sterile Insect Technique (SIT): This is a significant application area. It can be used to irradiate pupae of agricultural pests (e.g., Mediterranean fruit fly) or mosquitoes to render them sterile, thereby supporting green, pollution-free population control programs. Material Modification Research: Can be used to study the effects of X-rays on the properties of various materials (e.g., polymers, semiconductors). IV. Typical Model Parameters (Using WBK-01 as an example) X-ray Tube Voltage: Adjustable based on requirements, typically within a range from several tens to hundreds of kilovolts (kV), to suit different penetration depths and dose rate needs. Dose Rate: Can be adjusted based on voltage, current, and distance to meet the specific requirements of different experimental protocols. Uniformity: Ensured through optical system design and a sample rotation mechanism, guaranteeing uniform dose distribution within the irradiation field for reliable experiments. Summary The core value of the Dandong Tongda X-ray Irradiator lies in its replacement of inconvenient radioactive isotope sources with a safe, controllable, electrically generated X-ray source. It does not pursue excessive features but focuses on providing a stable, reliable, compliant, and easy-to-manage irradiation tool for scientific research and industrial applications. For laboratories seeking alternatives to isotopes or planning to establish new irradiation platforms, this is a practical piece of equipment worthy of evaluation and consideration by users in basic research and applied fields.

The multi-functional residual stress analyzer developed by Dandong Tongda Technology Co., Ltd. is designed to meet the needs of fast and accurate measurements in both laboratory and field environments. Based primarily on the X-ray diffraction principle, it enables non-destructive testing of the residual stress state inside materials. Versatile All-in-One Analysis This analyzer integrates multiple material analysis functions, significantly enhancing equipment utility and efficiency: Residual Stress Analysis: Supports various measurement modes such as standard同倾法 (omega-inclination), standard侧倾法 (psi-inclination), and standard摇摆法 (oscillation), capable of determining principal stresses and shear stresses for a comprehensive stress state evaluation. Retained Austenite Analysis: Employs the four-peak method for retained austenite testing, with fully automated data calculation for quick results. Diffraction Phase Analysis: Used to analyze crystal structures, chemical composition content, and distribution, helping researchers gain deeper insights into material constitution. Grain Size Analysis: Supports grain size evaluation from nanoscale to sub-micron scale, particularly suitable for fine grains ≤200 nm. Technical Features and Performance This instrument boasts multiple technical features aimed at ensuring precision, stability, and ease of use: High-Precision Measurement and Control: Utilizes a high-precision fully closed-loop vector drive servo system to ensure measurement accuracy and repeatability. Efficient Data Acquisition: Equipped with a multi-channel silicon strip linear array detector, which provides noise-free performance, high-intensity measurement, and rapid data collection to enhance detection efficiency. Portable Design: Features a lightweight construction, making it suitable not only for laboratory environments but also for on-site rapid measurements, adapting to various testing scenarios. User-Friendly Operation: Integrates Windows OS or automation functions, supporting one-click testing and real-time result display, lowering the operational barrier. Modularity and Safety: Employs a PLC control system with modular design for ease of operation and stable performance. Safety-wise, its low-power X-ray design complies with relevant safety standards, with radiation levels significantly below the annual public dose limit. Broad Application Fields Dandong Tongda’s multi-functional residual stress analyzer has extensive applications, covering almost all industrial sectors and research institutions requiring evaluation of material mechanical properties: Manufacturing Quality Control: Used to detect residual stresses in stamped, cast, and rolled parts during processing. Automotive Industry: Tests residual stresses in critical components such as camshafts and connecting rods to ensure reliability and durability. Aerospace: Evaluates working loads in critical areas of aerospace materials to assess safety. Materials Science Research: Applicable to various metal materials (e.g., carbon steel, alloy steel, titanium alloy, nickel-based materials), glass, and composite materials for residual stress, retained austenite, phase, and grain size analysis. Dandong Tongda Technology Co., Ltd.’s multi-functional residual stress analyzer demonstrates the company’s technical expertise in the field of material testing by integrating multiple analytical functions. This instrument provides engineers and researchers with a window into the intrinsic stress state of materials, helping to control product quality at the source, optimize process parameters, and thereby enhance product reliability and durability.

In the field of modern technology, many high-tech products—from smartphone screen substrates to core components of laser generators—rely on a fundamental material: synthetic single crystals. The precision of the cutting angle of these crystals directly determines the performance and yield of the final products. The X-Ray Orientation Analyzer is an indispensable instrument in the precision manufacturing of crystal devices. Utilizing the principle of X-ray diffraction, it accurately and rapidly measures the cutting angles of both natural and synthetic single crystals, including piezoelectric crystals, optical crystals, laser crystals, and semiconductor crystals. Dandong Tongda Science and Technology Co., Ltd. offers a range of reliable X-Ray Orientation Analyzers tailored to the research, processing, and manufacturing needs of the crystal materials industry. 01 Versatile Machine for Diverse Crystal Orientation Needs Dandong Tongda's X-Ray Orientation Analyzers primarily include models such as the TYX-200 and TYX-2H8. The TYX-200 model boasts a measurement accuracy of ±30″, with a digital display and a minimum reading of 10″. The TYX-2H8 model is an improved version of the TYX-200, featuring enhancements in the goniometer structure, load-bearing track, X-ray tube sleeve, support body, and an elevated sample stage. These improvements enable the TYX-2H8 to handle samples weighing 1–30 kg with diameters of 2–8 inches. It retains a digital angle display and a measurement accuracy of ±30″. 02 Advanced Technical Features for User-Friendly Operation Dandong Tongda's X-Ray Orientation Analyzers are designed with practicality and reliability in mind. Their user-friendly operation requires no specialized knowledge or advanced skills from the operator. The instrument features a digital angle display, ensuring intuitive and easy-to-read measurements while minimizing the risk of misreading. The display can be zeroed at any position, allowing direct reading of the wafer angle deviation. Some models are equipped with dual goniometers for simultaneous operation, significantly improving detection efficiency. A special integrator with peak amplification enhances measurement accuracy. The X-ray tube and high-voltage cable adopt an integrated design, improving high-voltage reliability. The detector high-voltage system uses a DC high-voltage module, and the vacuum suction sample stage further enhances measurement accuracy and speed. 03 Dedicated Sample Stage Designs for Various Testing Needs To meet the measurement requirements of samples with different shapes and sizes, Dandong Tongda offers a variety of specialized sample stages: TA Sample Stage: Designed for rod-shaped crystals, it features a load-bearing track and can test crystal rods weighing 1–30 kg with diameters of 2–6 inches (expandable to 8 inches). This stage can measure reference surfaces of rod-shaped crystals as well as surfaces of wafer-shaped crystals. TB Sample Stage: Also designed for rod-shaped crystals, it includes a load-bearing track and V-shaped support rails. It can test crystal rods weighing 1–30 kg, with diameters of 2–6 inches (expandable to 8 inches) and lengths of up to 500 mm. It measures end faces of rod-shaped crystals and surfaces of wafer-shaped crystals. TC Sample Stage: Primarily used for detecting the outer reference surfaces of single-crystal wafers such as silicon and sapphire. Its open-design suction plate avoids X-ray obstruction and positioning inaccuracies. The stage's suction pump securely holds wafers sized 2–8 inches, ensuring precise detection. TD Sample Stage: Designed for multi-point measurements of wafers such as silicon and sapphire. Wafers can be manually rotated on the stage (e.g., 0°, 90°, 180°, 270°) to meet specific customer measurement needs. 04 High-Performance Model for Large Sample Challenges For large and challenging sample detection, Dandong Tongda's X-Ray Orientation Analyzers demonstrate exceptional performance. The TYX-2H8 model, for example, is particularly suitable for orienting sapphire crystal ingots and rods. This instrument supports measurements of sapphire A, C, M, and R crystal orientations, with an adjustable measurement range of 0–45° via electric automation. Its technical specifications are impressive: Copper-target X-ray tube with grounded anode and forced air cooling. Adjustable tube current: 0–4 mA; tube voltage: 30 kV. Operation via computer or touchscreen control. Synchronized movement of the X-ray tube and detector; electric-driven rotary table. Total power consumption: ≤2 kW. Most notably, its sample handling capacity includes crystal ingots weighing up to 30–180 kg, with maximum dimensions of 350 mm in diameter and 480 mm in length. These capabilities make it suitable for large sample detection in most industrial scenarios. 05 Broad Applications Supporting Multiple Industries Dandong Tongda's X-Ray Orientation Analyzers are widely used across various industries involved in the research, processing, and manufacturing of crystal materials. In the semiconductor industry, they enable precise orientation cutting of silicon wafers. In the optoelectronics field, they are used for precision processing of sapphire substrates, optical crystals, and laser crystals. In the piezoelectric materials sector, they ensure accurate cutting angle measurements for stable end-product performance. The instruments are particularly well-suited for sapphire materials, which are in high demand due to their hardness, high light transmittance, and excellent physicochemical stability. Sapphire is widely used in LED substrates, consumer electronic screens, and optical windows. Dandong Tongda's X-Ray Orientation Analyzers have become essential tools in China's crystal material research and manufacturing fields, thanks to their reliable performance, diverse configurations, and strong adaptability. Their modular design and variety of sample stage options allow users to select configurations that meet specific needs, ensuring high detection accuracy while improving work efficiency. Whether for research institutions or manufacturing quality control and process optimization, these instruments provide robust technical support, empowering users to achieve breakthroughs in precision manufacturing.